Micro-crosslinking elastomer foaming material as well as preparation method and application thereof

A foaming material and micro-crosslinking technology, which is applied in the field of elastomer foaming materials, can solve problems such as creep, poor dimensional stability, and permanent deformation of melted polymers in crystal regions, and achieve reduced permanent deformation and good dimensional stability , Increase the effect of foaming ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

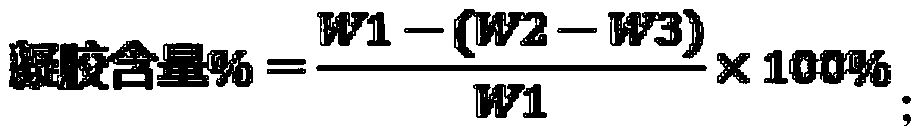

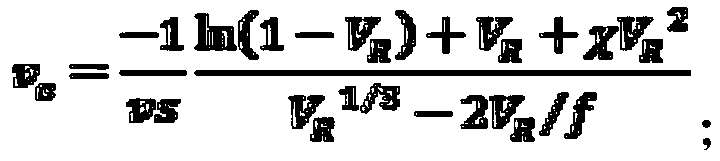

[0021] The invention provides a kind of preparation method of micro-crosslinked elastomer foaming material, comprises the following steps:

[0022] S1. Carry out cross-linking reaction on the low-melting point thermoplastic elastomer to obtain a slightly cross-linked vulcanizate with a gel content of no more than 60 wt%; the low-melting point elastomer is selected from one of EVA, POE, OBC, EPDM and SEBS or various;

[0023] S2. Saturating the micro-crosslinked vulcanized rubber with a physical foaming agent, and after the saturation is balanced, the micro-crosslinked elastomer foam material is obtained by raising the temperature or releasing the pressure.

[0024] In order to improve the foaming properties of low-melting thermoplastic elastomers, reduce the permanent deformation of foam materials during use, and have better dimensional stability, the present invention provides a foamable micro-crosslinked thermoplastic elastomer that can be melted and recycled. The method of...

Embodiment 1

[0049] EPDM (EPDM, Dow, 4820P) was selected as the base material. First, EPDM was put into an internal mixer, mixed at 80°C for 4 minutes, then 0.2phr of BIPB was added, and the internal mixing was continued for 4 minutes. Then the rubber is discharged, and after standing for 24 hours, the positive vulcanization time t of the rubber at 180°C is measured by a vulcanization meter. 90 . Next, place the obtained rubber material in a mold with a thickness of 1mm, and heat press it with a flat vulcanizer at a pressure of 10MPa at a temperature of 180°C. 90 +2min, take out the sample and cool for 5min to obtain a slightly crosslinked vulcanizate with a thickness of 1mm, a gel content of 45wt%, and a crosslinking density of 6.0×10 -6 mol / cm 3 .

[0050] The micro-crosslinked vulcanizate prepared in this example was placed in an autoclave for gas saturation. The saturated gas was carbon dioxide, the saturation pressure was 5 MPa, the saturation temperature was 25°C, and the saturati...

Embodiment 2

[0059] In addition to using 20MPa / 90℃ supercritical N 2 It is a foaming agent, except for depressurizing physical foaming, other operations are the same as in Example 1; an EPDM foaming material with a micro-crosslinked structure is obtained by physical foaming.

[0060] The density of EPDM foam material is 0.05g / cm 3 , The magnification is 17.2 times, the dimensional shrinkage rate after heat treatment at 70°C / 40min is 4%, and the foaming material is melted and molded to obtain a transparent film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Crosslink density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com