HDPE (high-density polyethylene)/LDPE (low-density polyethylene) blended foam material and preparation method thereof

A foaming material and blending technology, which is applied in the field of foaming materials and their molding, can solve the problems of non-uniform properties of foaming materials and uneven mixing of materials, and achieve uniform cells, good compatibility and uniform material properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

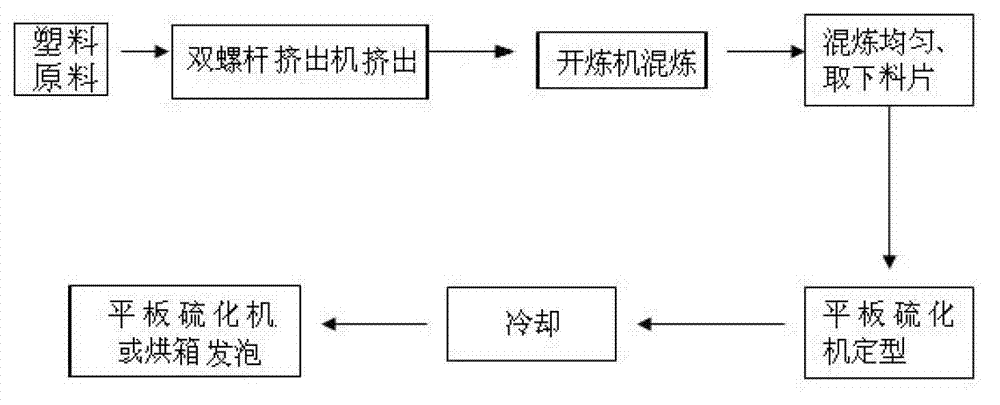

Method used

Image

Examples

Embodiment 1

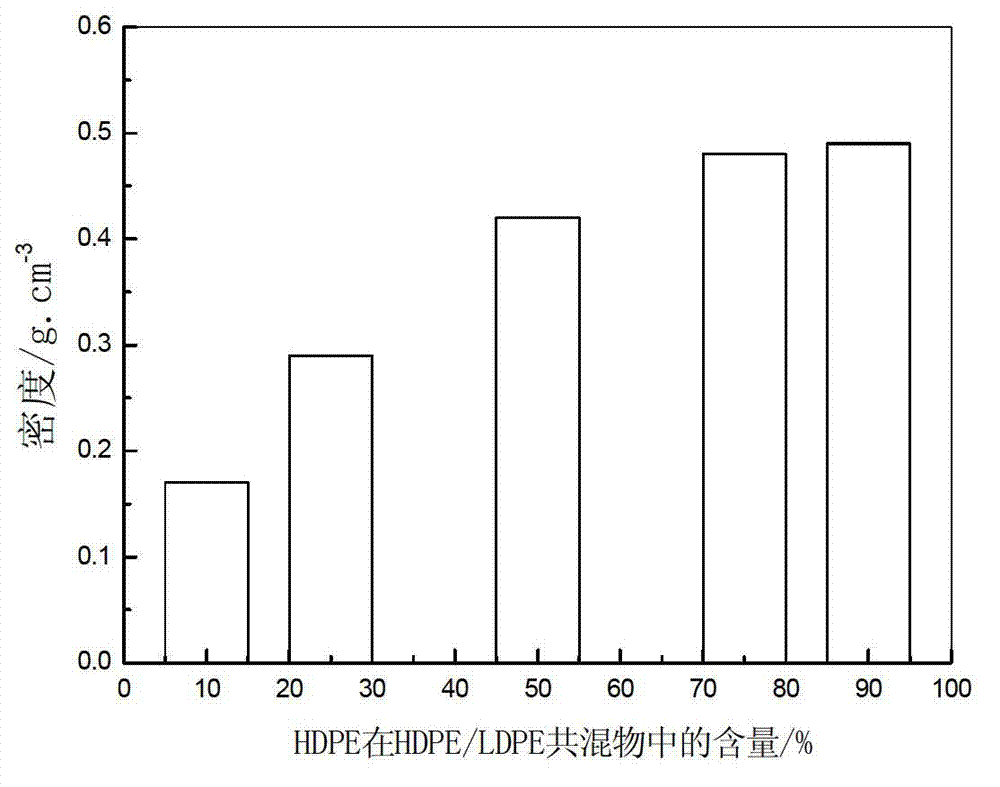

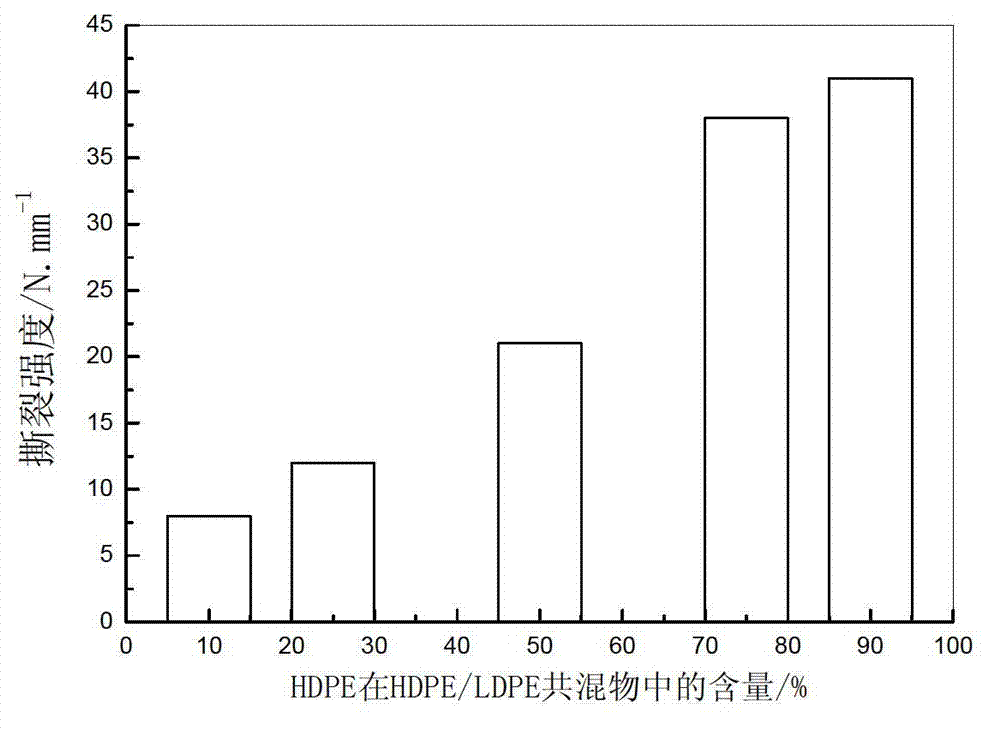

[0059] The foaming formula is: 10 parts of HDPE, 90 parts of LDPE, 0.5 parts of dicumyl peroxide (DCP), 3 parts of Ac foaming agent, 1.3 parts of zinc oxide, 0.5 parts of stearic acid, and 0.1 part of antioxidant 1010 , 3 parts of inorganic filler calcium carbonate.

[0060] Process:

[0061] (1) Mix HDPE and LDPE on a high-speed mixer according to the ratio, and then extrude the mixture through a twin-screw extruder to granulate. The temperature settings of each zone of the twin-screw extruder are shown in Table 3. ℃ drying for 8 hours to obtain a dry base material;

[0062] (2) Plasticize the dried blend in an open mill with a roll temperature of 143°C, gradually add other additives, and finally add foaming agent, and make triangular bags 5 times until the blend is evenly mixed , remove the sheet and flatten it while it is hot;

[0063] (3) Preform the tablet in a mold frame at 150°C with a pressure of 5 MPa for 10 minutes, and foam the prepared sample sheet on a flat vul...

Embodiment 2

[0068] The foaming formula is: 25 parts of HDPE, 75 parts of LDPE, 0.5 parts of benzoyl peroxide (BPO), 5 parts of Ac foaming agent, 1.5 parts of zinc oxide, 0.5 parts of stearic acid, 0.1 parts of antioxidant 1010 parts, 6 parts of inorganic filler mica powder.

[0069] Process:

[0070] (1) Mix HDPE and LDPE on a high-speed mixer according to the ratio, and then extrude the mixture through a twin-screw extruder to granulate. The temperature settings of each zone of the twin-screw extruder are shown in Table 3. ℃ drying for 8 hours to obtain a dry base material;

[0071] (2) Plasticize the dried blend in an open mill with a roll temperature of 144°C, gradually add other additives, and finally add foaming agent, and make triangular bags 6 times until the blend is evenly mixed , remove the sheet and flatten it while it is hot;

[0072] (3) Preform the sheet in a mold frame at 150°C with a pressure of 5 MPa for 10 minutes, and foam the prepared sample sheet on a flat vulcaniz...

Embodiment 3

[0077] The foaming formula is: 50 parts of HDPE, 50 parts of LDPE, 0.5 parts of dicumyl peroxide (DCP), 7 parts of Ac foaming agent, 1.7 parts of zinc oxide, 0.5 parts of stearic acid, and 1010 antioxidants 0.1 part, 9 parts of inorganic filler calcium carbonate.

[0078] Process:

[0079] (1) Mix HDPE and LDPE on a high-speed mixer according to the ratio, and then extrude the mixture through a twin-screw extruder to granulate. The temperature settings of each zone of the twin-screw extruder are shown in Table 3. ℃ drying for 8 hours to obtain a dry base material;

[0080] (2) Plasticize the dried blend in an open mill with a roll temperature of 145°C, gradually add other additives, and finally add foaming agent, and make triangular bags 7 times until the blend is evenly mixed , remove the sheet and flatten it while it is hot;

[0081] (3) Preform the sheet in a mold frame at 150°C with a pressure of 5 MPa for 10 minutes, place the prepared sample sheet in an electric heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com