A kind of polypropylene foam composition and its preparation method and application

A polypropylene foam and composition technology, applied in plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve the problem of difficult to meet the requirements of thin-walled insulating layer communication cables, difficult to obtain small diameter cells, and unsuitable for communication. Cable and other problems, to achieve the effect of improving melt strength and processability, high physical heat resistance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the polypropylene foam composition in the specific embodiment of the present invention, comprises the following steps: take the polypropylene of formulation amount, high melt strength polypropylene, high density polyethylene, ethylene-propylene copolymer and siloxane coupling The agent was stirred for 4 minutes in a mixer with a stirring speed of 400r / min; then the foaming agent, antioxidant and lubricant in the formula amount were added, and mixed evenly; then the mixed raw materials were banburyed, melted and blended in an internal mixer, and then Melt, mix and extrude through a single-screw extruder to obtain the product; the temperature of the banburying and melt-blending is 158° C., and the time for banburying and melt-blending is 3 minutes; the screw length-to-diameter ratio of the single-screw extruder Its ratio of 25:1, the melting and mixing temperature of the single-screw extruder is 140-175°C, and the melting and mixing time of the si...

Embodiment

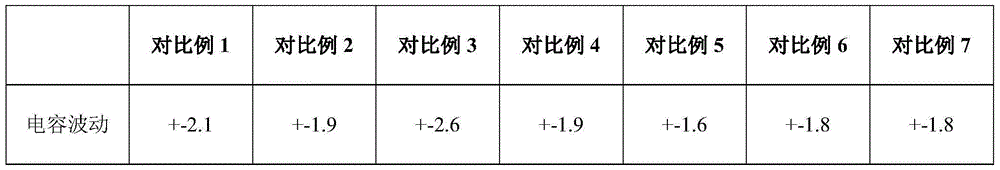

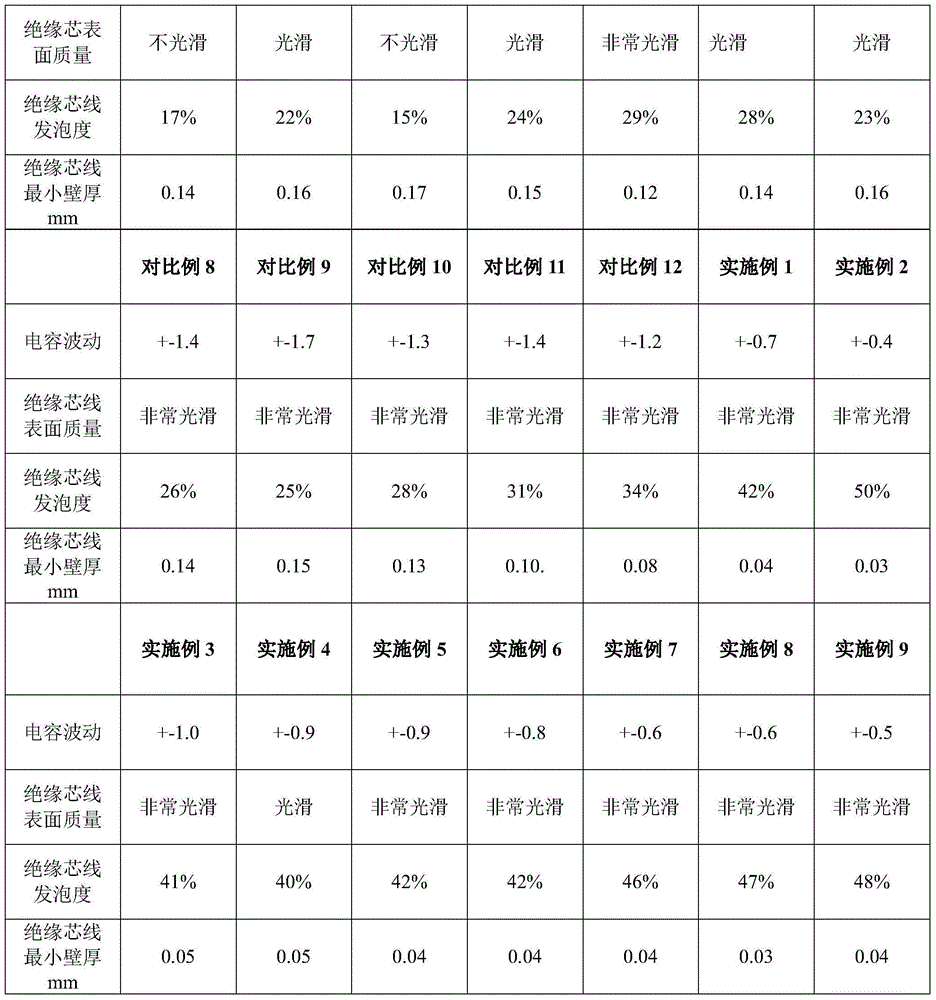

[0034] Examples, comparative examples

[0035] In this embodiment, the components of Comparative Examples 1-12 and Examples 1-2 are detailed in Table 1 below, where the numbers in Table 1 represent mass percentages, such as PP in Comparative Example 1, and the data in the table It is 98.7, which means that in the polypropylene foam composition of Comparative Example 1, PP accounts for 98.7% of the total amount of the polypropylene foam composition.

[0036] Table 1: the formula table of comparative example 1-12, embodiment 1-2

[0037]

[0038] HSMPP

experiment example

[0040] Get the polypropylene foam composition of embodiment 1-2, comparative example 1-12, then to the performance test of above-mentioned composition, test index comprises density, melt index, tensile strength, elongation at break density, heat distortion temperature and dielectric constant. Among them, density is tested according to ASTM D792 standard, melt index (230°C / 2.16KG) is tested according to ASTM D1238 standard, tensile strength is measured according to ASTM D638-2008 standard, elongation at break is measured according to ASTM D638-2008 standard, heat distortion temperature Measured in accordance with the ASTM D638 standard, and the dielectric constant is tested in accordance with ASTM 1531; the specific test results are shown in Table 2 below:

[0041] Table 2: The performance test data table of the polypropylene foam composition of Examples 1-2 and Comparative Examples 1-12

[0042]

Comparative example 1

Comparative example 2

Comparative exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com