A method for automatic control of large valve switching of ethylene cracking furnace

An ethylene cracking furnace, automatic control technology, applied in non-electric variable control, electric fluid pressure control, hydrocarbon cracking and hydrocarbon production, etc., can solve downstream compression, separation system fluctuations, large impact on equipment body, and low operation fault tolerance rate and other issues to achieve the effect of reducing post-system fluctuations, improving stability, and increasing fault tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0039] Taking the large valve switching control process of a 1 million t / h ethylene cracking furnace in a factory as an example, the steps are as follows:

[0040] (1) First, initialize and check the initial allowable work, so that the related valves such as the cracked gas valve are in normal working condition, and at the same time, the furnace COT, dilution steam flow, furnace negative pressure, furnace SS temperature, large valve pressure difference, large valve The pressure parameters of anti-coke steam are within the range of process requirements, and the preparation state of related blind plate and root valve public works shall be confirmed;

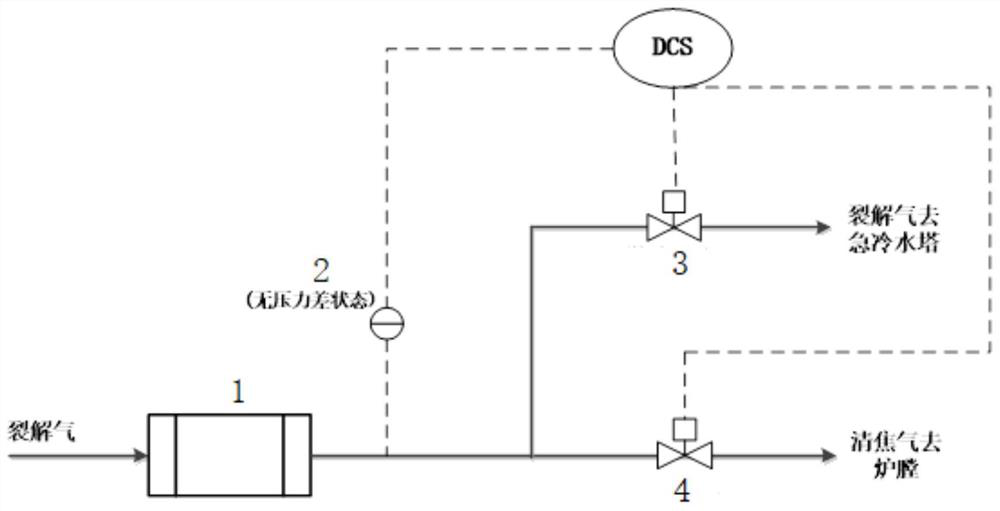

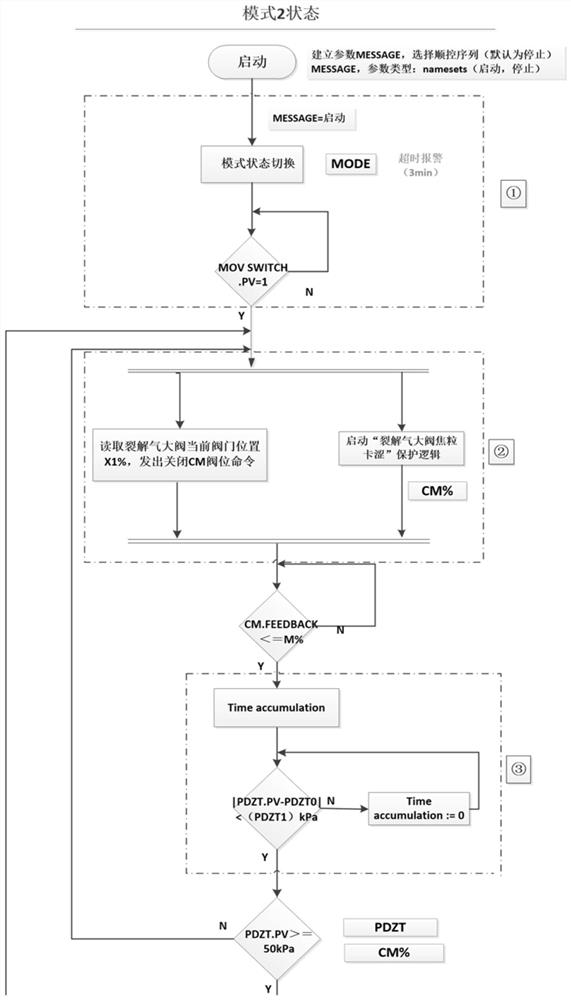

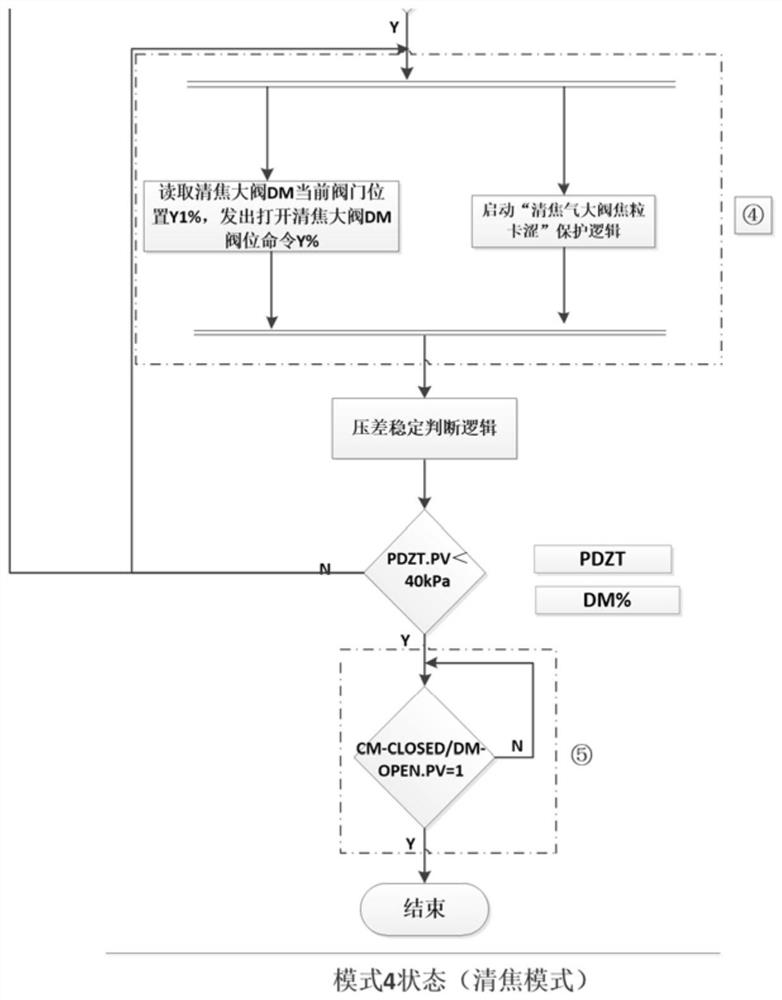

[0041] (2) Switch the cracking furnace mode from the hot standby mode to the large valve automatic switching mode. After detecting the status feedback parameter of the large valve automatic switching mode, based on the DCS, the cracking gas large valve closing command is issued, and the cracking gas large valve coke particles are st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com