High-performance TA1 bar wire and preparation method thereof

A high-performance, silk technology, applied in the direction of improving process efficiency, can solve problems such as enterprise losses, and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

[0039] 1. The experimental material uses grade 0 special sponge titanium with a C content of 0.012%. According to the requirements of the present invention, the alloy components are mixed. See Table 2. The balance is titanium and unavoidable impurities.

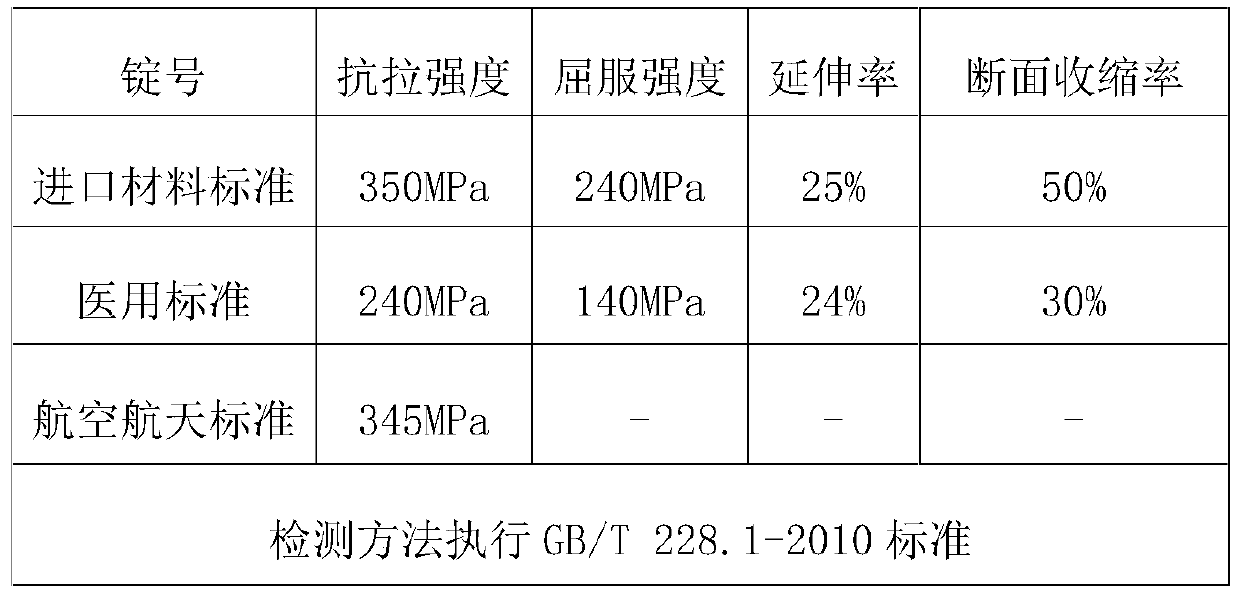

[0040] Table 2 Chemical composition of titanium alloy (wt%)

[0041] FeCNOH Requirements of the invention≤0.15≤0.10≤0.03≤0.15≤0.008 Example 10.1380.0140.0140.1450.001 Example 20.1430.0120.0160.1320.001

[0042] 2. The electrode is pressed by a 3500 ton hydraulic press, and then smelted in a vacuum consumable melting furnace into a Ф450mm ingot.

[0043] 3. After the ingot is peeled on the surface, the riser and the bottom are removed, the billet forging is carried out in a 2500 ton hydraulic press, the forging temperature is 1000 ℃, the heat preservation is 300 min, and the forging to a square billet with a side length of 150 mm, Surface defects such as pits and folds are trimmed clean.

[0044] 4. After grinding, the qualifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com