A kind of PET electroplating decorative film production process and its production equipment

A production process and electroplating equipment technology, applied in the field of PET electroplating decorative film production process and production equipment, can solve problems such as low yield of electroplating decorative film, reduce the proportion of defective products, ensure production quality, and improve yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

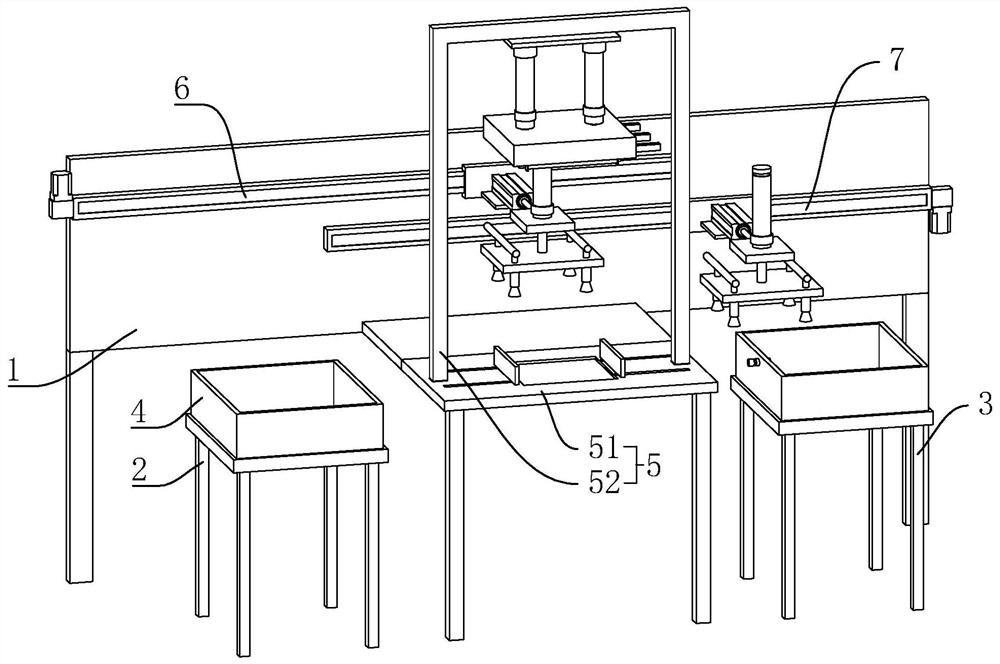

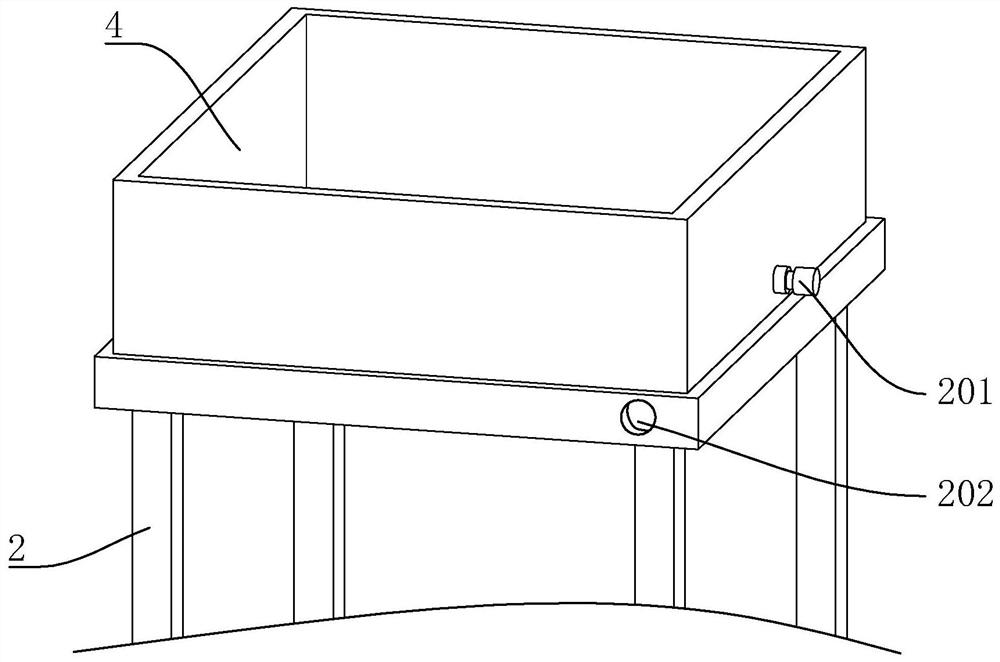

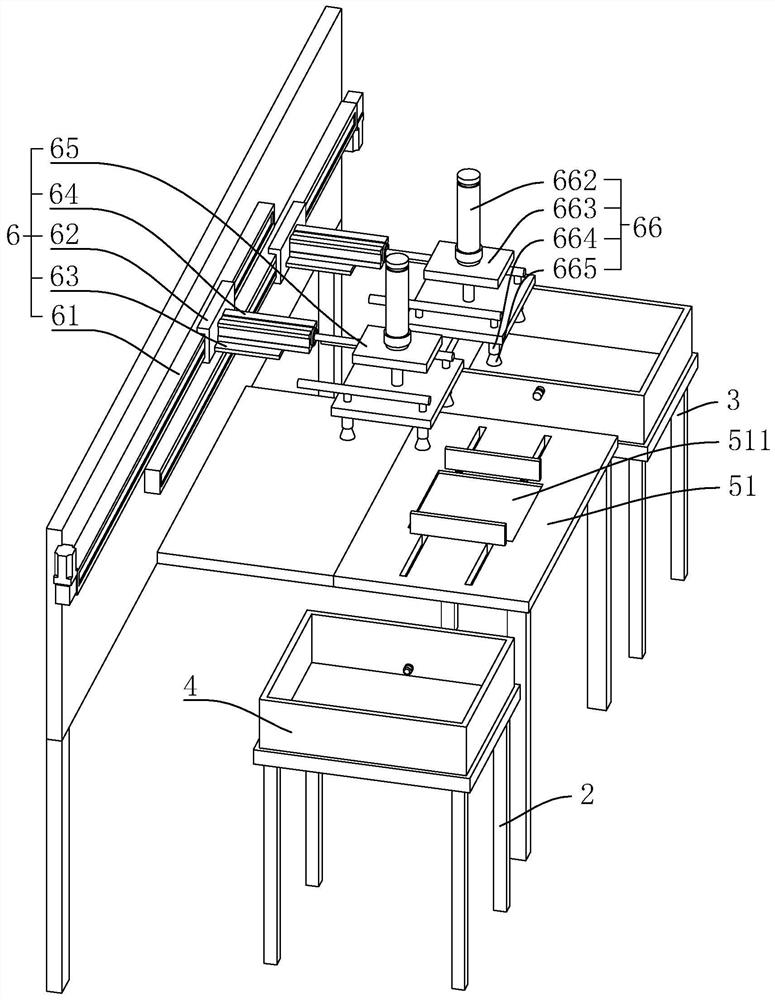

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0052] A PET electroplating decorative film production process, comprising the following production steps:

[0053] Step1: Use roll-to-roll electroplating equipment to plate the corresponding film layer on the PET film;

[0054] Step2: Print the corresponding protective ink on the PET film that has been coated;

[0055] Step3: Laser cutting the PET film that has been printed with protective ink, and cutting it into the corresponding required shape pattern;

[0056] Step4: Detect the finished PET film after cutting;

[0057] Step5: Cut the finished PET film after the inspection to divide it into PET electroplating decorative films of the same size. During the electroplating process of the PET film, the PET film needs to be cooled synchronously. During the production of the PET electroplating decorative film At this time, the PET film is first electroplated,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com