A method for replenishing water during the coating process of a paper coating machine

A coating machine and paper technology, applied in the process of adding pulp raw materials, paper, paper machines, etc., can solve the problems of difficulty in meeting, water loss, long distance, etc., and achieve the effect of avoiding excessive water replenishment at one time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for replenishing water in a coating machine coating process of coated paper, the method comprising the following steps:

[0031] (1) The moisture content in the original coated paper is measured by a moisture measuring instrument to be 3.5%, and the required water replenishment amount is calculated to be 2% according to the national standard reference value of 5.5%.

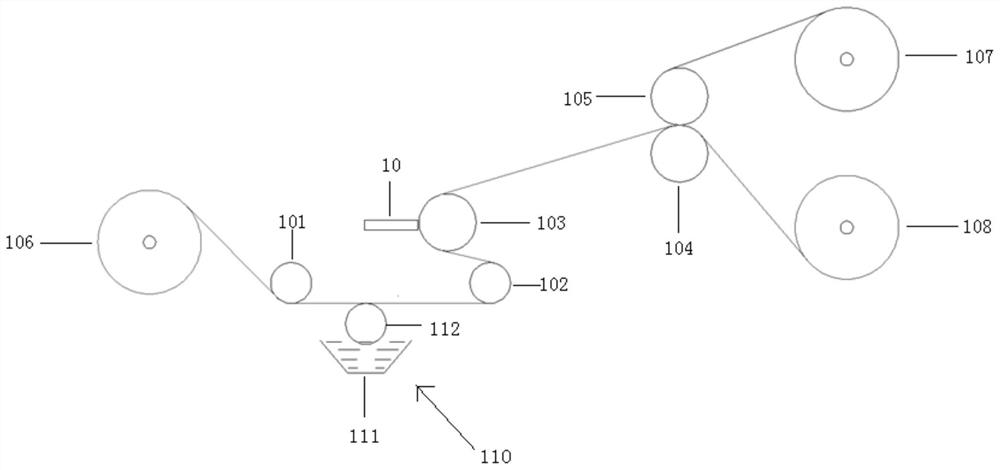

[0032] (2) Set the parameters of the above-mentioned roller water replenishing device (set the water replenishment amount to 2%), so that the original coated paper contacts the roller water replenishing device through the lower surface of the original coated paper before it travels to the coating head of the coating machine The roller shaft absorbs liquid water to obtain the first replenishment, and the coated paper after the first replenishment travels to the coating head of the coating machine for thermal coating;

[0033] (3) The moisture content in the coated paper after hot gluing is measured...

Embodiment 2

[0041] A method for replenishing water in a coating machine coating process of writing paper, the method comprising the following steps:

[0042] (1) The moisture content in the original writing paper is measured by a moisture measuring instrument to be 4%, and the required water replenishment amount is calculated to be 2% according to the reference value of the national standard of 6%.

[0043] (2) Set the parameters of the roller water replenishment device (set the water replenishment amount to 2%), so that the original writing paper contacts the roller shaft water replenishment device through the lower surface of the original writing paper before it travels to the coating head of the coating machine. The roller shaft absorbs the liquid water to obtain the first replenishment, and the writing paper after the first replenishment travels to the coating head of the coating machine for thermal coating;

[0044] (3) Using a moisture measuring instrument to measure the moisture co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com