Support device for early-demolished formwork

A technology of supporting device and early dismantling of formwork, applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problem of poor corrosion resistance, etc. The effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The preparation method of graphene oxide is obtained by referring to the method shown in Example 1 in the Chinese patent application number 201710096249.0.

[0064] Calcium fluoride, CAS number: 7789-75-5, product number XF123, purchased from Lingshou County Xinfu Mineral Products Processing Factory.

[0065] Sodium lauryl sulfate, CAS number: 151-21-3, model K12, was purchased from Shandong Baiqian Chemical Co., Ltd.

[0066] Aluminum, block, 25kg / block, type A00 aluminum ingot, aluminum content ≥ 99.99%, purchased from Tianjin Boyate Metal Material Trading Co., Ltd.

[0067] Strontium, particles, 19 mm in diameter, were purchased from Anaiji Chemical Co., Ltd.

[0068] Cerium, massive, 0.5kg / block, brand HR-1, was purchased from Sichuan Lanshi Rare Earth Materials Co., Ltd.

[0069] Hexachloroethane, CAS number: 67-72-1, product number: H811176, purchased from Shanghai Macklin Biochemical Technology Co., Ltd.

[0070] The stirring equipment is YCJB1200 permanent ma...

Embodiment 1

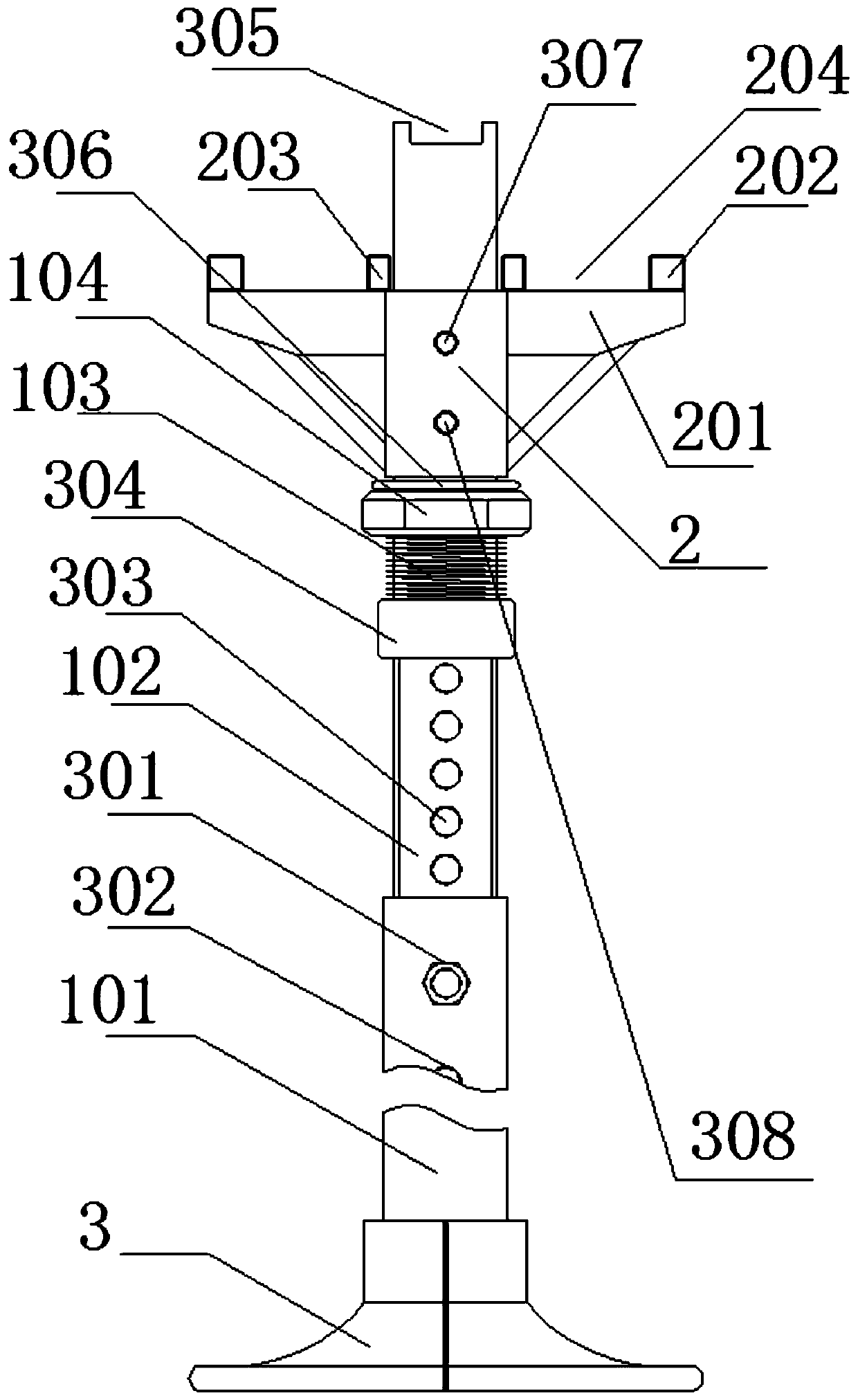

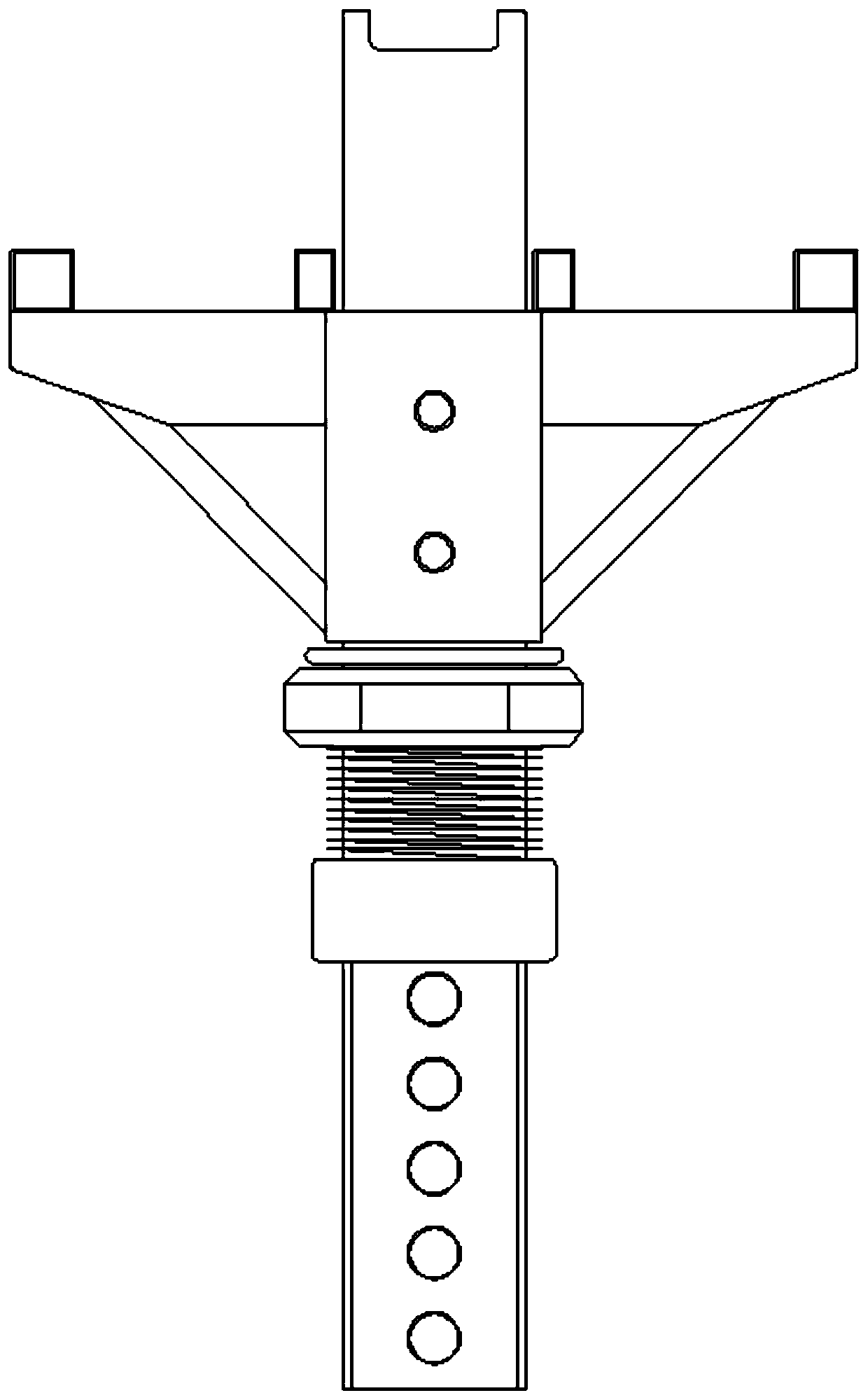

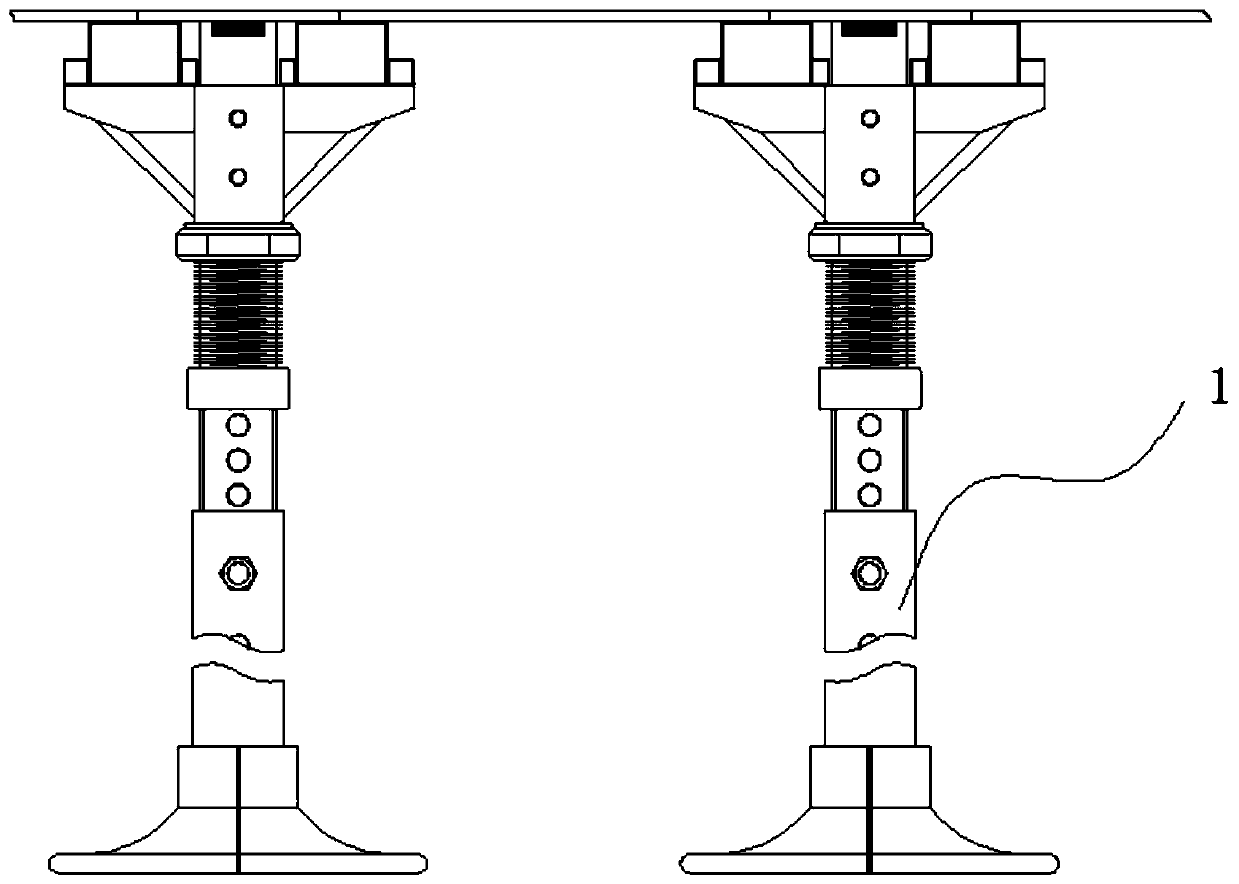

[0073] The bottom fixed rod 101 is provided with a fixed base 3 near the bottom, the fixed base 3 is provided with two pieces, and the position between the two fixed bases 3 and the bottom fixed rod 101 is provided with a connection Screws (not shown).

[0074]Two or more connecting bolts 301 are arranged at the position between the support rod 102 and the bottom fixing rod 101, and the through holes 302 matching the connecting bolts 301 are arranged at the position on the surface of the bottom fixing rod 101. The position on the surface of the support rod 102 is provided with first through holes 303 for fitting the connecting bolts 301 , and the distance between the through holes 302 is greater than the distance between the first through holes 303 .

[0075] A connecting collar 304 for connecting the bottom fixing rod 101 is provided on the surface of the support rod 102 .

[0076] A first installation slot 305 is provided at a middle position on the top surface of the suppo...

Embodiment 2

[0083] The bottom fixed rod 101 is provided with a fixed base 3 near the bottom, the fixed base 3 is provided with two pieces, and the position between the two fixed bases 3 and the bottom fixed rod 101 is provided with a connection Screws (not shown).

[0084] Two or more connecting bolts 301 are arranged at the position between the support rod 102 and the bottom fixing rod 101, and the through holes 302 matching the connecting bolts 301 are arranged at the position on the surface of the bottom fixing rod 101. The position on the surface of the support rod 102 is provided with first through holes 303 for fitting the connecting bolts 301 , and the distance between the through holes 302 is greater than the distance between the first through holes 303 .

[0085] A connecting collar 304 for connecting the bottom fixing rod 101 is provided on the surface of the support rod 102 .

[0086] A first installation slot 305 is provided at a middle position on the top surface of the supp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com