Fully-mechanized excavating continuous construction forepoling system and method

A technology of advanced support and fully mechanized excavation, which is used in earth-moving drilling, mine roof support, mining equipment, etc., can solve the problems of parallel operation of excavation and support, etc., so as to improve support efficiency, reduce time and effort, and improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

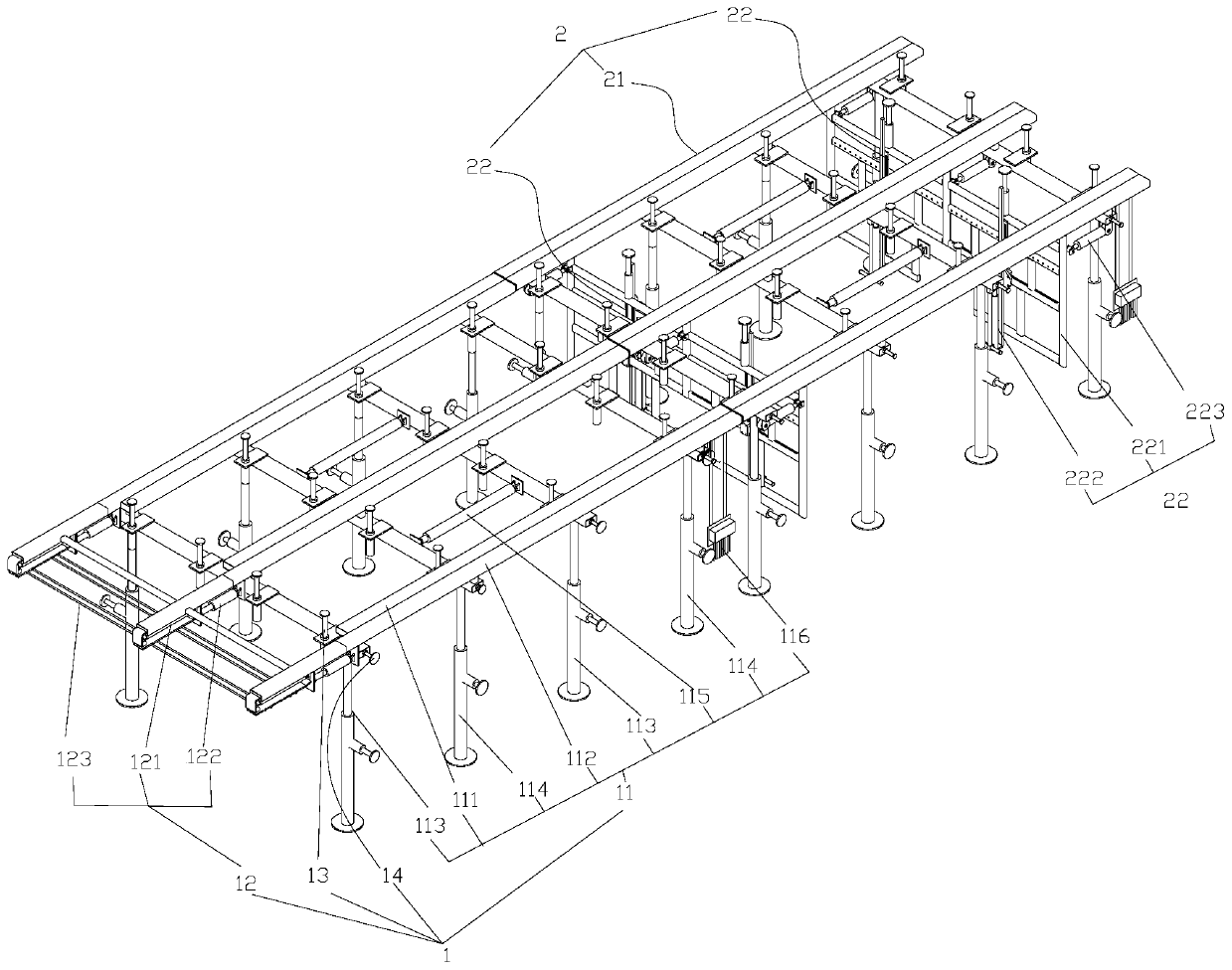

[0046] like figure 1 As shown, the advanced support system for the continuous construction of fully mechanized excavation in the roadway includes the first bracket group 1 and the second bracket group 2 arranged continuously. The first bracket group 1 includes the first self-moving bracket 11, the upper anchor net mechanism 12, the upper anchor The net mechanism 12 is installed on the end of the first self-moving support 11 away from the second support group 2, the left end in the figure;

[0047] The second bracket group 2 includes a second self-moving bracket 21 and two groups of bolt drill parts 22, and the bolt drill parts 22 are vertically installed at both ends of the second mobile bracket 21;

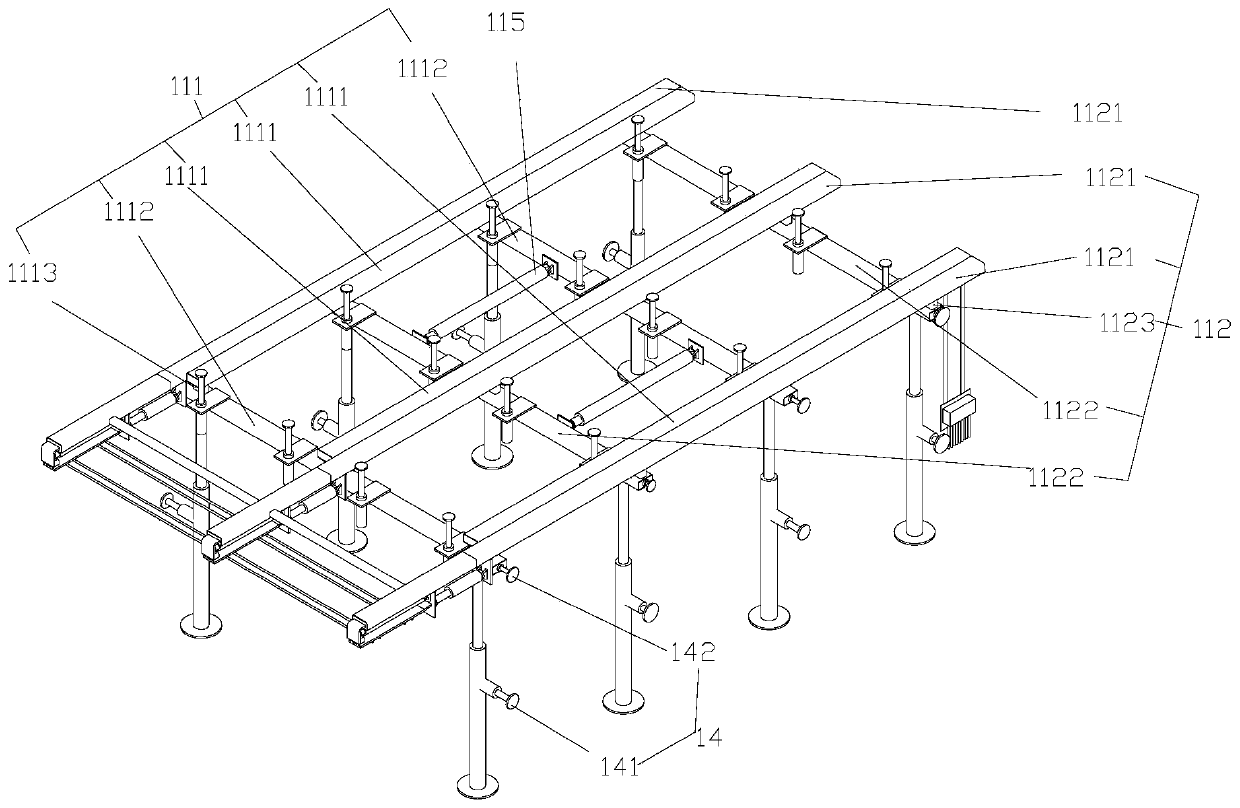

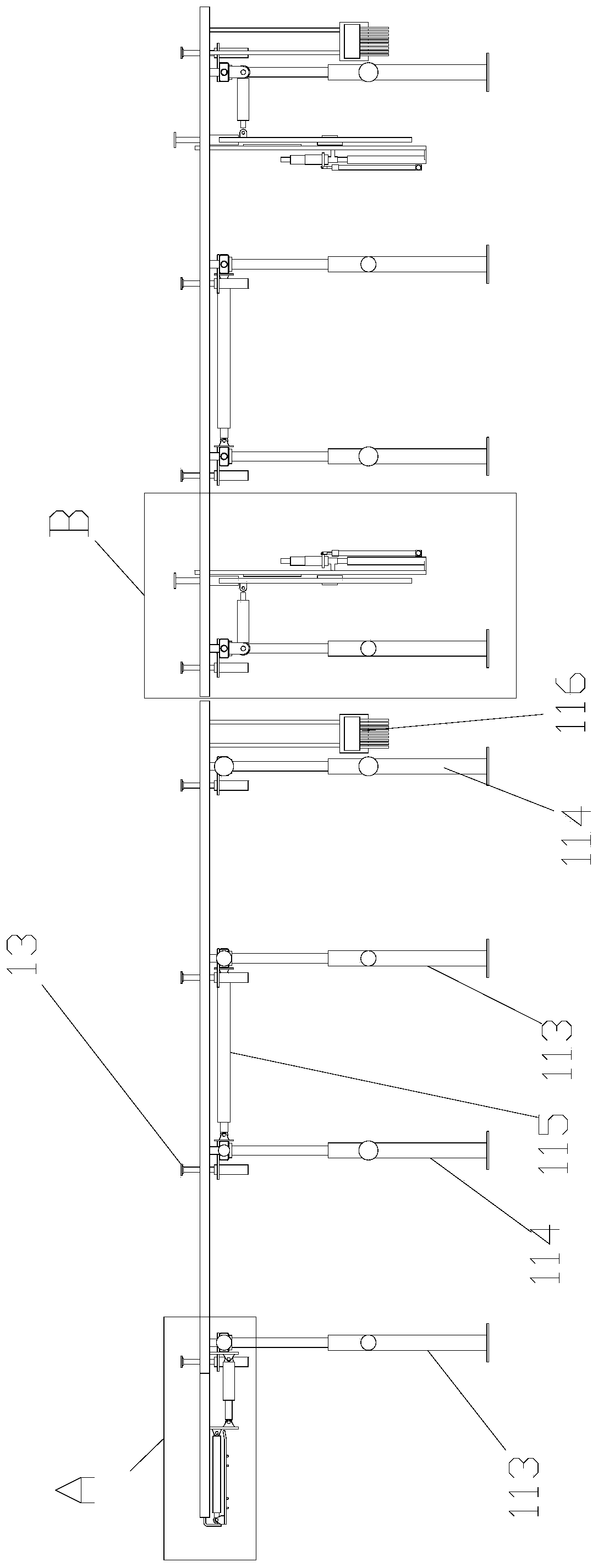

[0048] combine figure 2 , image 3 As shown, in this embodiment, the first self-moving support 11 and the second self-moving support 21 have the same composition and structure. Here, the first self-moving support 11 is taken as an example. The first self-moving support 11 incl...

Embodiment 2

[0064] like Figure 9 As shown, the difference from the first embodiment above is that a third bracket group 3 is added between the first bracket group 1 and the second bracket group 2,

[0065] The third bracket group 3 also includes a third self-moving bracket, which is the same as the first self-moving bracket. The required equipment can be installed on the third self-moving support as required.

[0066] In the end, the first support group 1 is mainly used for the protection of the roadheader, the anchor net mechanism at the front, and the placement of equipment such as dust removal fans. 3 It is mainly used for the protection of the secondary transport belt at the rear of the roadheader to realize the automatic support function. In actual use, the length of the first group of supports is 8.5m, and the length of the second and third groups is 7.1m, which can also be adjusted according to the actual situation. The width is generally 4.7-5m according to the width of the roa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com