Trans-critical reciprocating piston compressor taking CO2 as refrigerant

A reciprocating piston, transcritical technology, applied in piston pumps, machines/engines, mechanical equipment, etc., can solve problems such as the hole in the ozone layer and the atmospheric greenhouse effect, and achieve the effects of reducing the friction coefficient, high compression efficiency, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

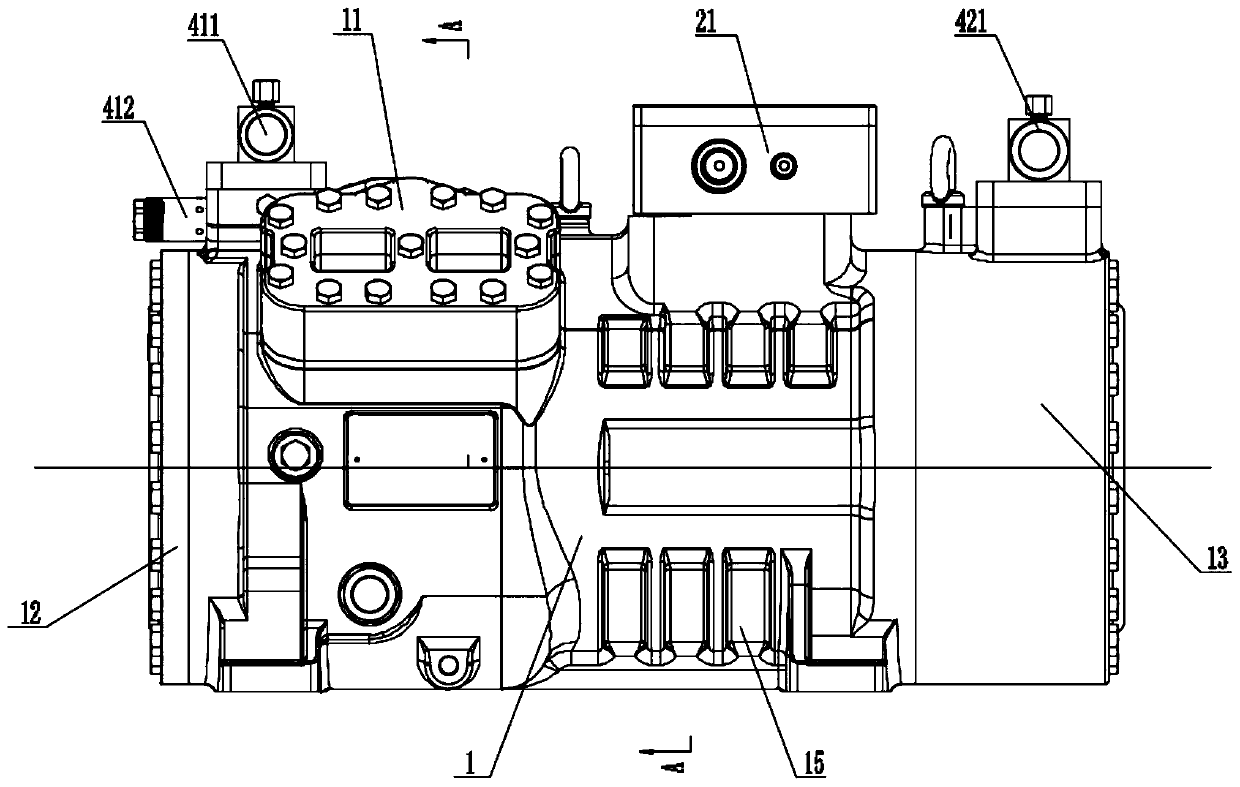

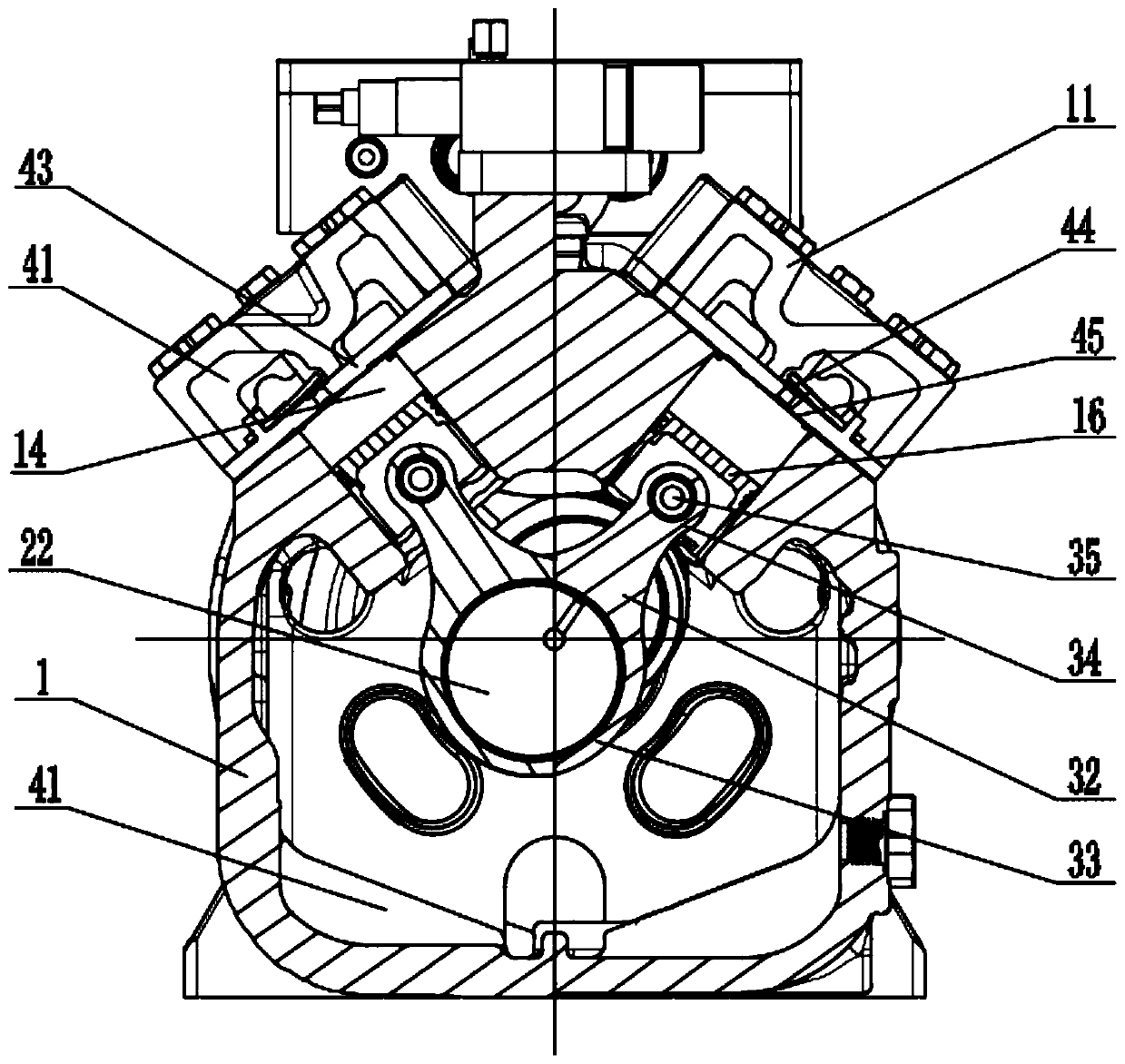

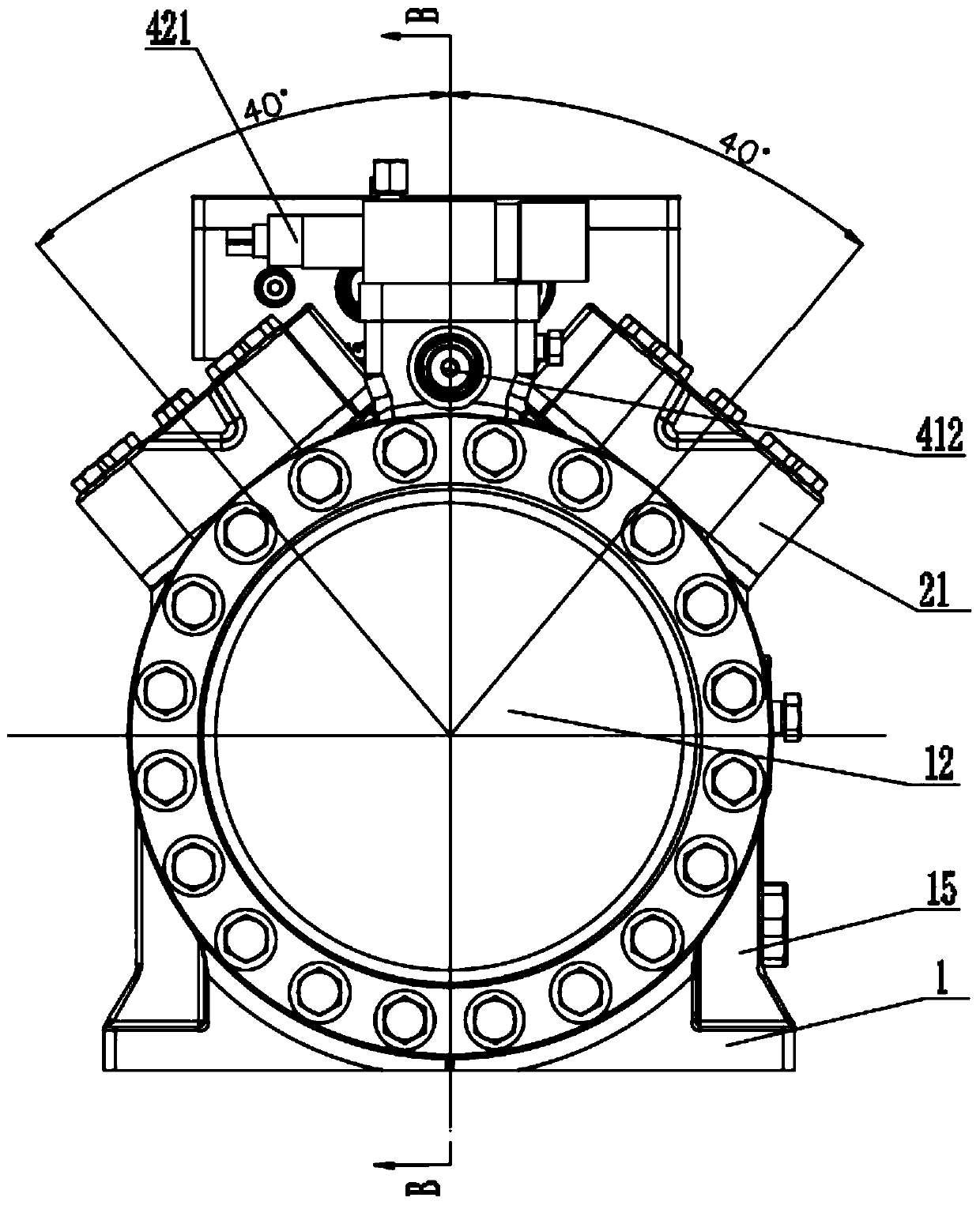

[0024] like Figure 1 to Figure 4 shown, a CO 2 A transcritical reciprocating piston compressor used as a refrigerant includes a body 1. Cylinder heads 11 are staggered on both sides of the body top of the body 1, and the cylinder heads 11 realize the isolation of high and low pressure CO. 2 gas. Air cylinders 14 are arranged inside the body 1, two on each side of the air cylinders 14, which are arranged in a V shape on both sides of the side of the body 1, and the angle formed by the cylinders 14 and the vertical axis of the body 1 is 40 degrees. A piston 16 is arranged inside the cylinder 14, and the piston 16 is made of aluminum alloy and is treated by anodizing process, which makes the piston 16 more wear-resistant, improves the service life of the cylinder 14, and indirectly increases the service life of the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com