Efficient energy-saving environment-friendly air return heating furnace

A high-efficiency energy-saving, heating stove technology, applied in the direction of household stove/stove, stove/stove top, space heating and ventilation, etc., can solve the problems of smoke pollution, single fuel, insufficient combustion, etc., and achieve improved combustion efficiency , easy to operate and use, good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

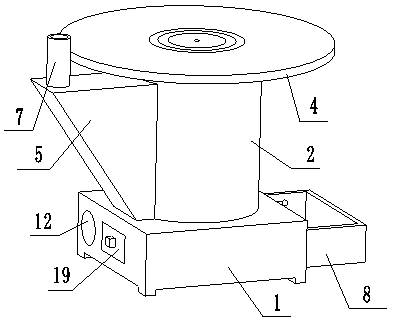

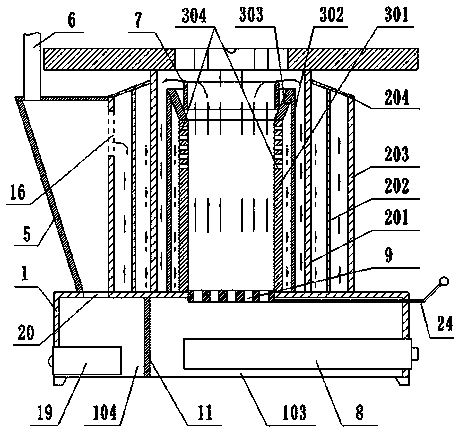

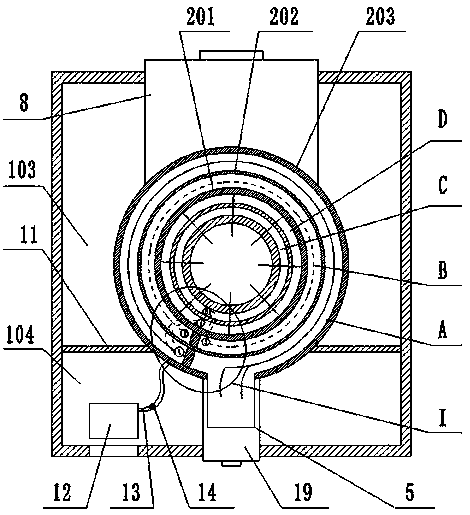

[0029] Such as Figure 1 to Figure 4 As shown, the high-efficiency, energy-saving and environment-friendly return air heating stove described in the present invention is mainly used as a heating stove for cooking, and can also be used as a heating stove for heating.

[0030] A high-efficiency, energy-saving and environment-friendly return air heating furnace includes a furnace base 1, a furnace body 2, a furnace core 3, a furnace panel 4 and a smoke exhaust chamber 5, and the furnace base 1, the furnace body 2 and the furnace panel 4 can be freely disassembled The furnace base 1 is a sealed structure with a cavity, and the furnace core 3 is arranged in the furnace body 2 and coaxially arranged on the furnace base with the furnace body 2. 1, the furnace panel 4 is arranged on the top of the furnace body 2, an opening communicating with the inner cavity of the furnace core 3 is provided on the top surface of the furnace base 1, and a furnace bridge 9 is provided at the opening; ...

Embodiment 2

[0038] Such as Figure 5 As shown, the high-efficiency, energy-saving and environment-friendly return air heating stove described in the present invention is mainly used as a heating stove for cooking, and can also be used as a stove for heating. factor.

[0039] The main structure of the return air heating furnace is basically the same as that of Embodiment 1, the only difference is that: a high-efficiency, energy-saving and environment-friendly return air heating furnace according to the present invention is provided with an anti-scalding net 205 on the outside of the furnace body 2 , the anti-scalding net 205 is arranged on the furnace base 1 and is located on the outer periphery of the outer furnace wall 203 , and a hollow body 206 is formed between the anti-scalding net 205 and the outer furnace wall 203 . The provided anti-scalding net 205 prevents contact with the outer furnace wall 203 during the heating process, thereby improving the safety of use.

Embodiment 3

[0041] Such as Figure 6 As shown, the high-efficiency, energy-saving and environment-friendly return air heating stove described in the present invention is mainly used as a heating stove for cooking, and can also be used as a stove for heating, and its purpose is to realize the sharing of firewood and coal.

[0042] The main structure of the return air heating furnace is basically the same as that of Embodiment 1, the only difference is that the high-efficiency, energy-saving and environment-friendly return air heating furnace of the present invention includes a hopper 17, and the hopper 17 is arranged in the ash box 8, under the action of external force, the hopper 17 can shrink inwardly with the ash box 8 in the furnace base 1, and is located directly below the furnace bridge 9, and a fire gathering ring is also provided in the base 1 18. The fire gathering ring 18 is arranged on the bottom surface of the furnace bridge 9 in a ring shape, and is located directly above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com