Cooling device for glass product

A cooling device and product technology, applied in household refrigeration devices, applications, household appliances, etc., can solve problems such as low cooling efficiency of cooling equipment, and achieve the effects of improving cooling efficiency, facilitating adjustment, and facilitating evaporative cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

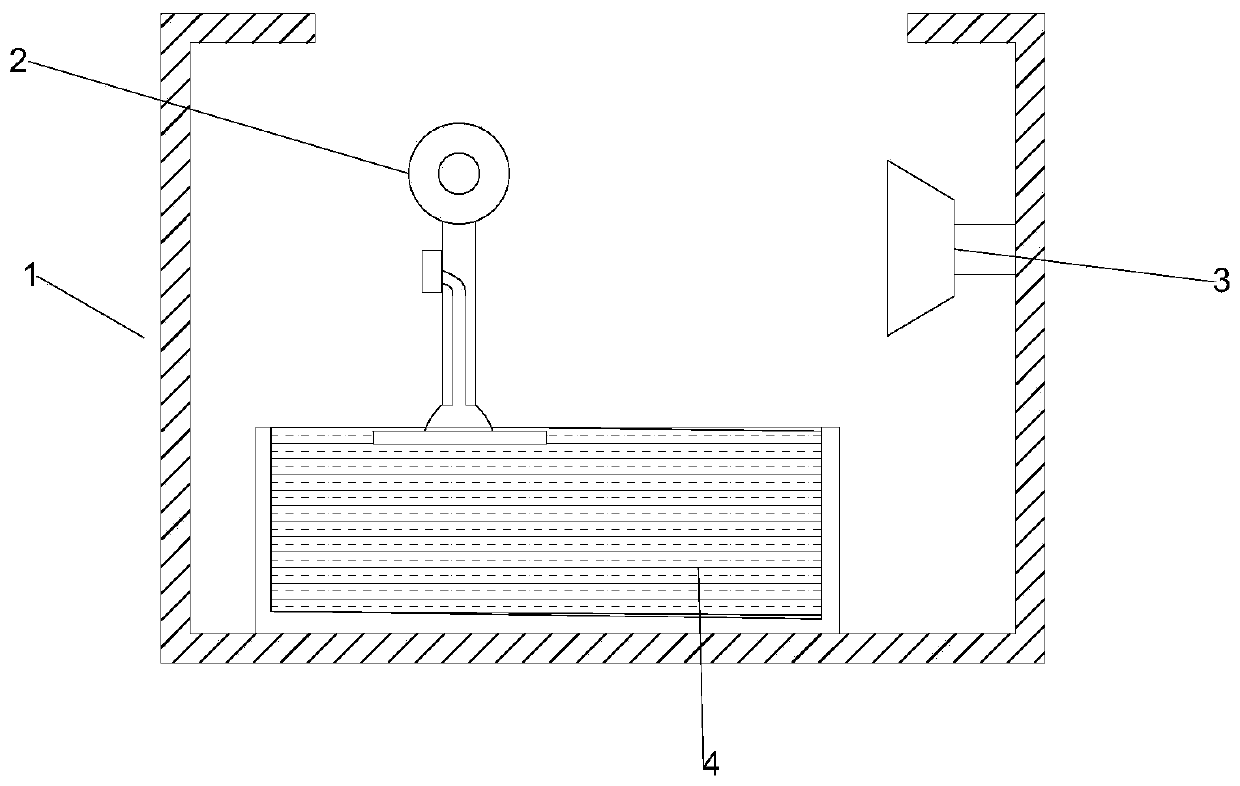

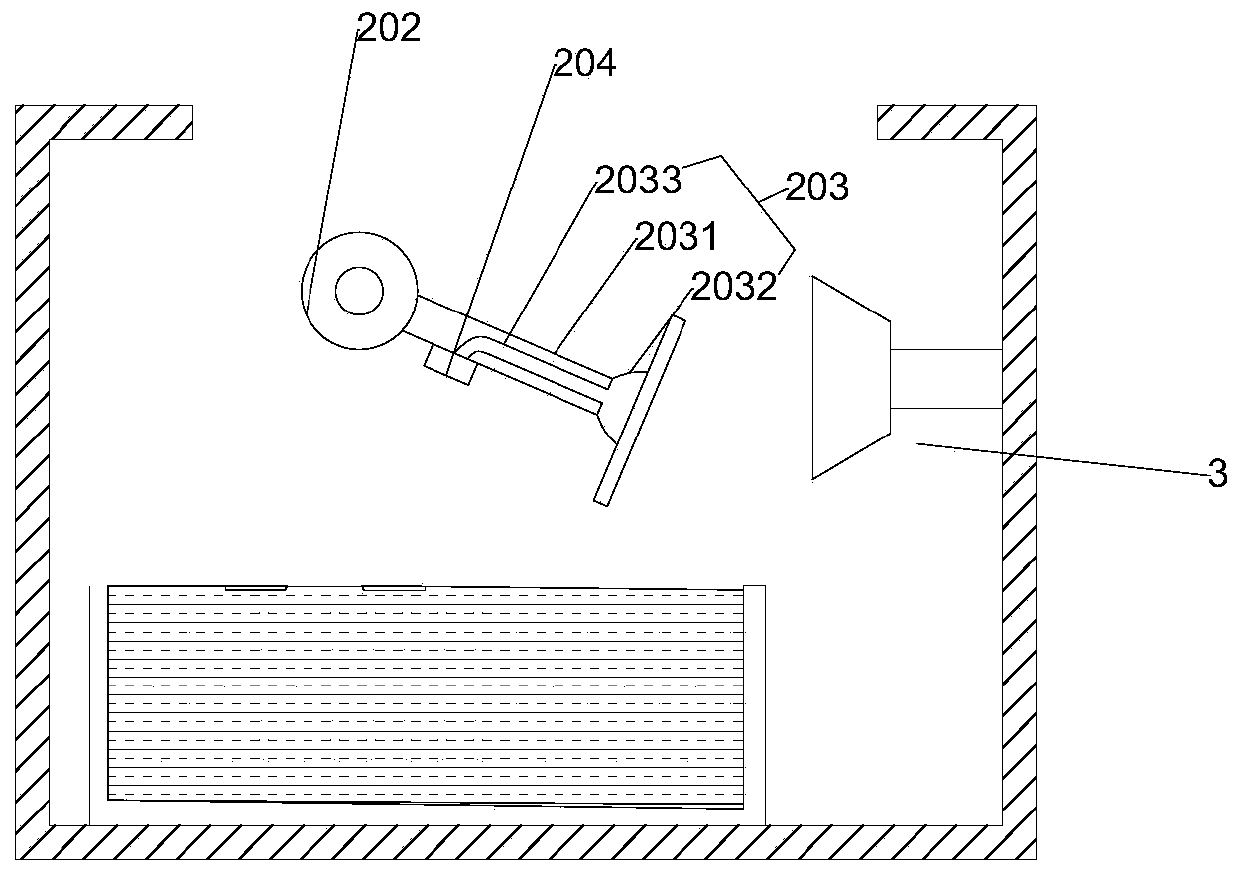

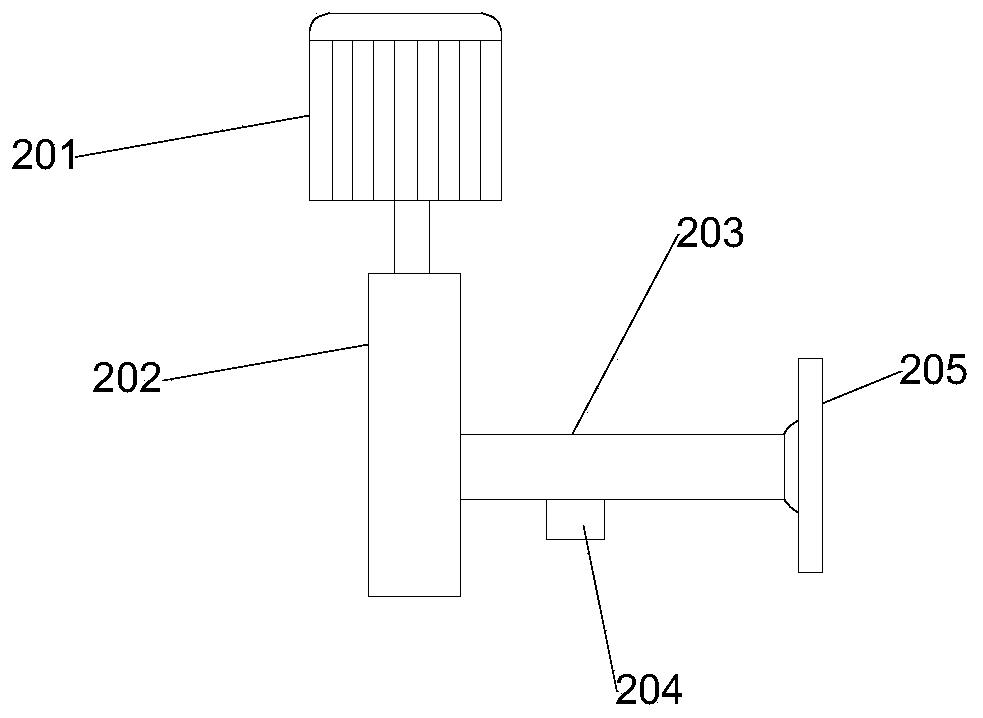

[0032] figure 1 It is a structural schematic diagram of a cooling device for a glass product in which the product to be cooled is at the lowest end in Example 1 of the present invention; figure 2 It is a structural schematic diagram of a cooling device for a glass product after the product to be cooled is rotated at a certain angle in Example 1 of the present invention; Figure 8 It is the overall three-dimensional schematic diagram of Embodiment 1 of the present invention; as figure 1 , figure 2 and Figure 8 , a cooling device for glass products, comprising a box body 1, a clamping mechanism 2, a drying mechanism 3, a cooling water tank 4 and a position adjustment mechanism 5, a cooling water tank 4 is placed at the bottom of the box body 1, and the cooling water tank 4. There is cooling water inside. The top of the cooling water tank 4 is provided with a clamping mechanism 2 fixedly connected to the inner side of the rear wall of the box body 1. The clamping mechanism ...

Embodiment 2

[0044] Figure 5 It is a structural schematic diagram of a cooling device for glass products in Example 2 of the present invention;

[0045] Figure 6 It is a three-dimensional schematic diagram of the position adjustment mechanism in Embodiment 2 of the present invention; Figure 7 It is a structural schematic diagram of a cooling device for a glass product after the position of the cooling device is adjusted in Example 2 of the present invention; Figure 5 , Figure 6 , Figure 7 The difference between embodiment 2 and embodiment 1 is that it also includes a position adjustment mechanism 5, which is fixedly connected to the side wall of the box body 1 by welding.

[0046] Such as Figure 5 and Figure 6 , the position adjustment mechanism 5 includes an arc-shaped plate 501, a connecting rod 502, a second magnet 503, a spring 504 and an arc-shaped slide rail 505, and the vertical section of the arc-shaped plate 501 is a fan-shaped mechanism whose center angle is greater...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap