Pressure sensor unit and pressure sensor

A pressure sensor, flexible conductive technology, applied in the field of flexible equipment, can solve the problems of non-conforming pressure sensor, difficult pressure sensor unit, low sensitivity resolution, etc., to improve sensitivity and resolution, uniform deformation, and increase detection range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

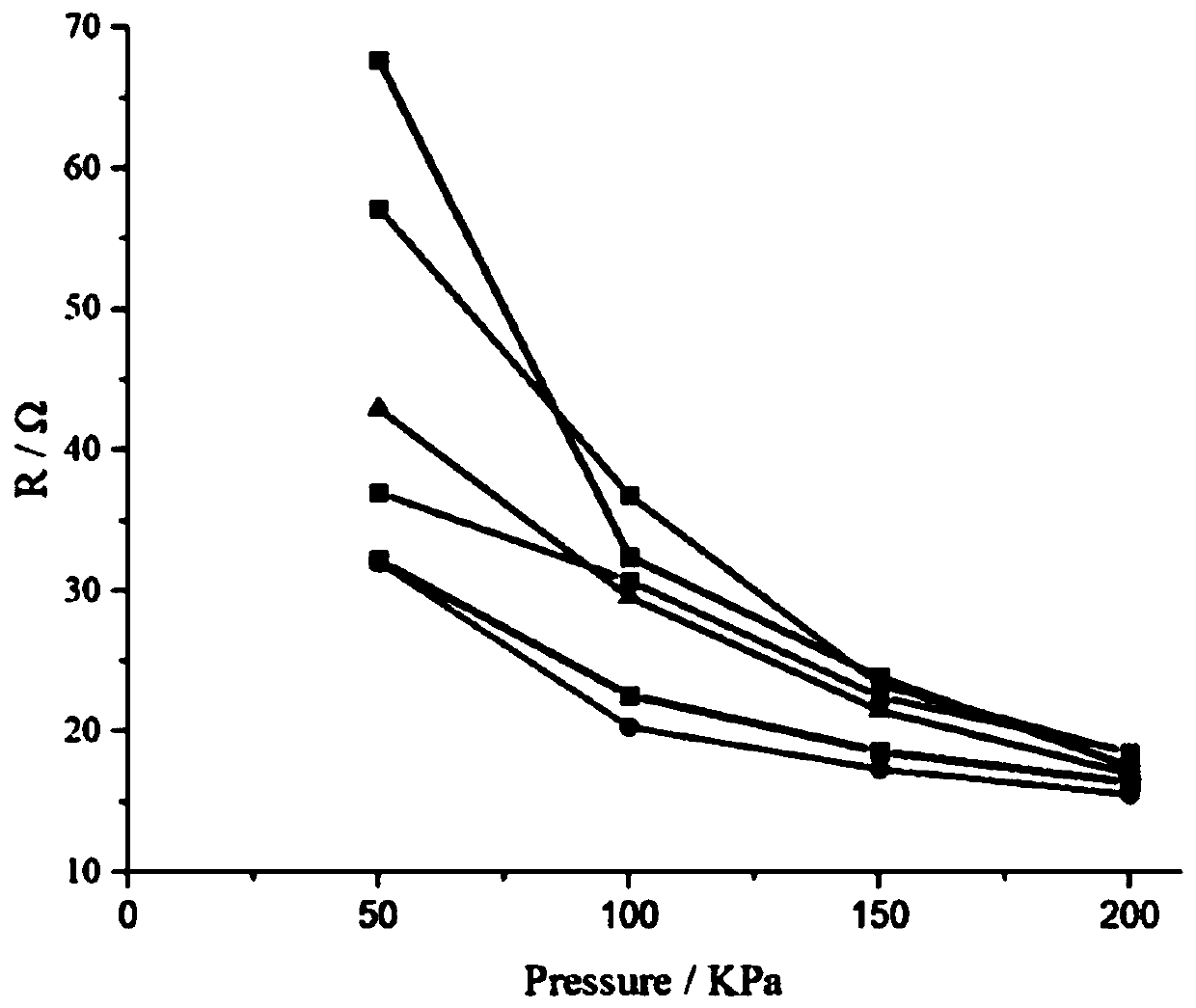

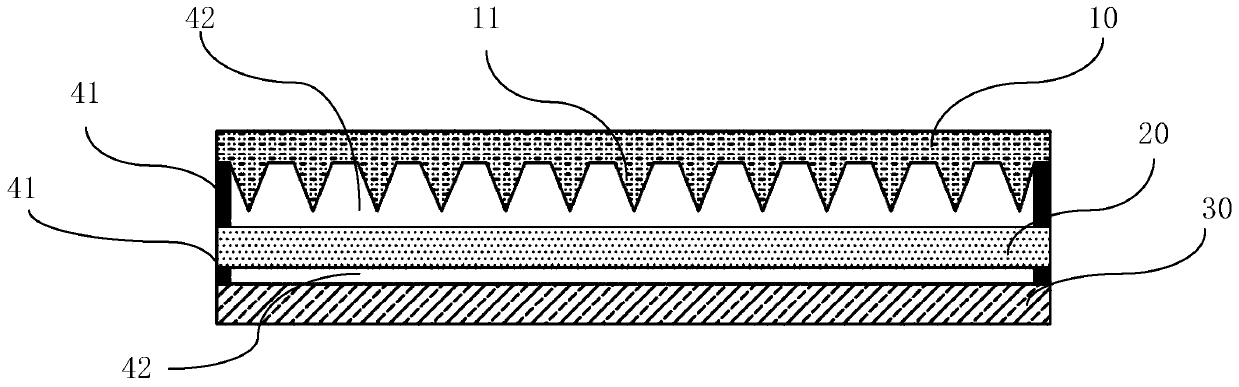

[0034] A polydimethylsiloxane film with a semicircular microstructure is used as the microstructure layer 10, wherein the semicircular microstructure has a radius of 250 microns and a uniform spacing of 500 microns. A highly flexible conductive film with pressure sensitive properties is used as the flexible conductive film layer 20, wherein the flexible conductive film layer 20 is a composite of styrene-butadiene block copolymer and multi-walled carbon nanotubes. The interdigital electrode layer 30 is an interdigital circuit prepared on a flexible circuit board. Use high-strength glue to bond and package the three along the outer non-working area. After the packaging is completed, use a constant loading pressure testing machine for calibration, and the calibration results are as follows Figure 4 ( Figure 4 The middle abscissa is the pressure applied to the pressure sensor unit, and the ordinate is the resistance measured by the pressure sensor unit under this pressure, the...

Embodiment 2

[0036]An Eco-flex film with a semicircular microstructure is used as the microstructure layer 10, wherein the radius of the semicircular microstructure is 100 microns, and the uniform spacing is 250 microns. A highly flexible conductive film with pressure sensitive properties is used as the flexible conductive film layer 20, and the flexible conductive film layer 20 is a composite of thermoplastic polyurethane and multi-walled carbon nanotubes. The interdigital electrode layer 30 is an interdigital circuit prepared on a flexible circuit board. Use high-strength glue to bond and package the three along the outer non-working area. After the packaging is completed, use a constant loading pressure testing machine for calibration, and the calibration results are as follows Figure 5 ; It has very good linearity, sensitivity, resolution and intrinsic repeatability relative to commercial pressure sensors.

Embodiment 3

[0038] A thermoplastic polyurethane film with a prism-shaped microstructure is used as the microstructure layer 10, wherein the side length of the prism-shaped microstructure is 500 microns, the depth is 250 microns, and the uniform spacing is 500 microns. A highly flexible conductive film with pressure sensitive properties is used as the flexible conductive film layer 20, and the flexible conductive film layer 20 is a composite of polydimethylsiloxane and activated carbon. The interdigital electrode layer 30 is an interdigital circuit prepared on a flexible circuit board. Use high-strength glue to bond and package the three along the outer non-working area. After the packaging is completed, use a constant loading pressure testing machine for calibration, and the calibration results are as follows Figure 6 ; It has very good linearity, sensitivity, resolution and intrinsic repeatability relative to commercial pressure sensors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com