Normal-temperature high-frequency cavity inlet power measuring device and method

A technology of power measurement and high-frequency cavity, which is applied in the field of power measurement device of normal temperature and high-frequency cavity into cavity, can solve the problems of broken cavity, inability to accurately measure deflection angle, small coupling degree, etc., so as to improve measurement accuracy and facilitate power consumption. Monitoring and closed-loop control of low-level systems, reducing the effect of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

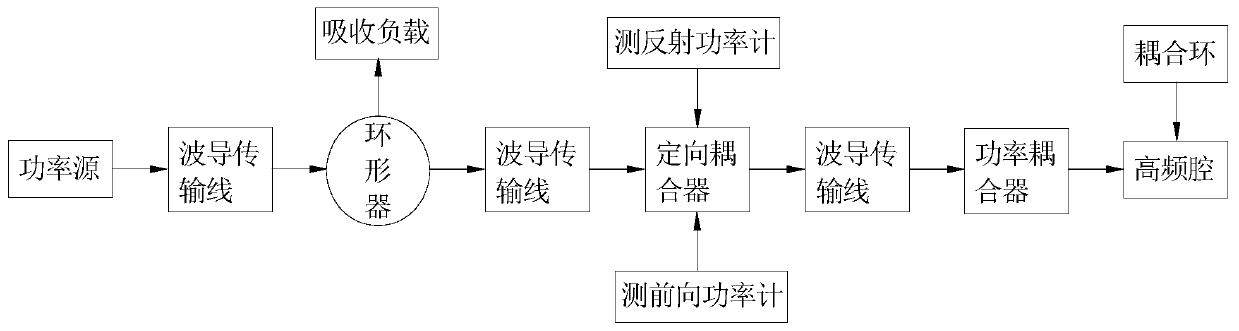

[0045] In this embodiment, a normal-temperature high-frequency cavity cavity power measurement device, such as figure 1 As shown, it includes a power source, a circulator, a directional coupler, a power coupler and a high-frequency cavity connected in sequence, among which, between the power source and the circulator, between the circulator and the directional coupler, and between the directional coupler and the power coupling The directional couplers are connected by waveguide transmission lines; the circulator is also equipped with an absorbing load, the high-frequency cavity is also equipped with a coupling ring, and the directional coupler is also equipped with a reflection power meter and a forward power meter. In the structure of the device, the directional coupler is similar to a transformer, and its main function is to take out a small part of the high microwave power for measurement by the reflected power meter and the forward power meter; the main function of the powe...

Embodiment 2

[0048] In this embodiment, a method for measuring the power of a room-temperature high-frequency cavity entering the cavity is realized by using the measuring device described in Embodiment 1.

[0049] The measurement method is to first calculate the entrance reflection coefficient of the high frequency cavity by measuring the field amplitude signal, phase angle signal and coupling degree of the high frequency cavity; then measure the reflected power and forward power of the directional coupler, and use the entrance reflection coefficient Calculate the power attenuation coefficient from the directional coupler to the entrance of the high-frequency cavity using the amplitude value; finally, use the power attenuation coefficient to calculate the forward power, reflected power and actual power entering the cavity at the entrance of the high-frequency cavity.

[0050] The concrete process of above-mentioned measurement method comprises the following steps:

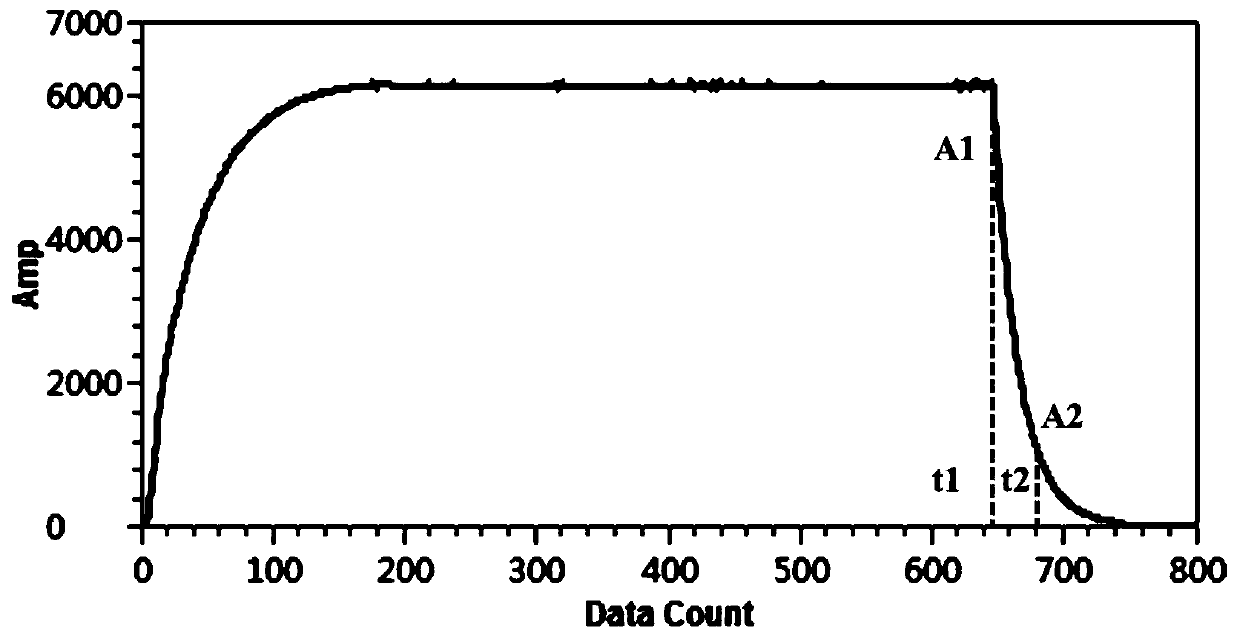

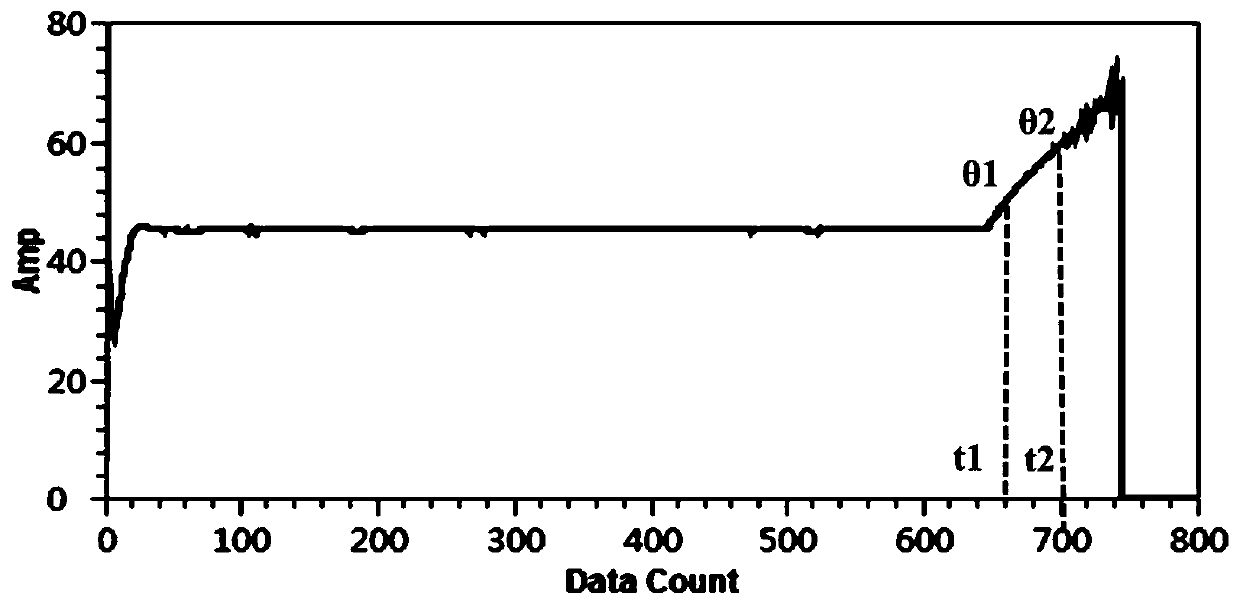

[0051] S1: Collect the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com