Three-dimensional photonic crystal and its application

A photonic crystal, three-dimensional technology, applied in optics, optical components, instruments, etc., can solve the problem of photonic band gap limitation, inability to form an effective band gap, and high incidence angle dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

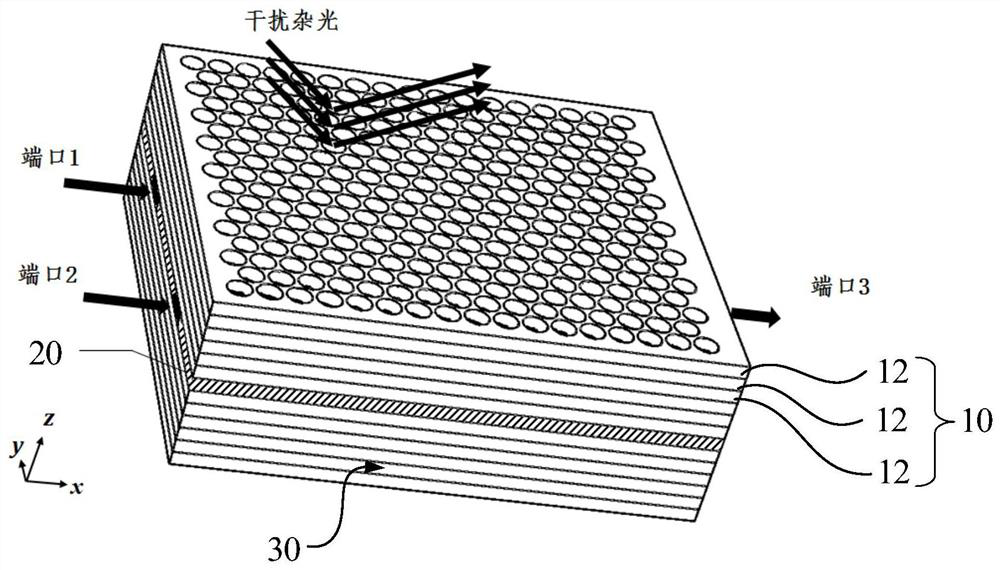

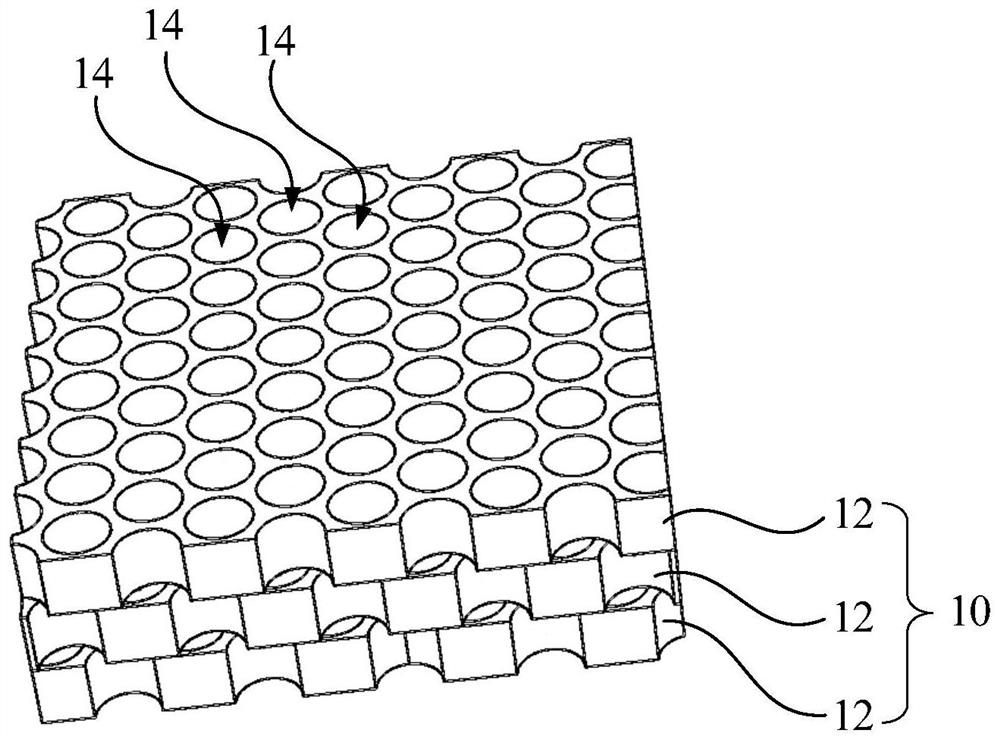

[0058] This example is prepared as figure 1 The 3D photonic crystal shown.

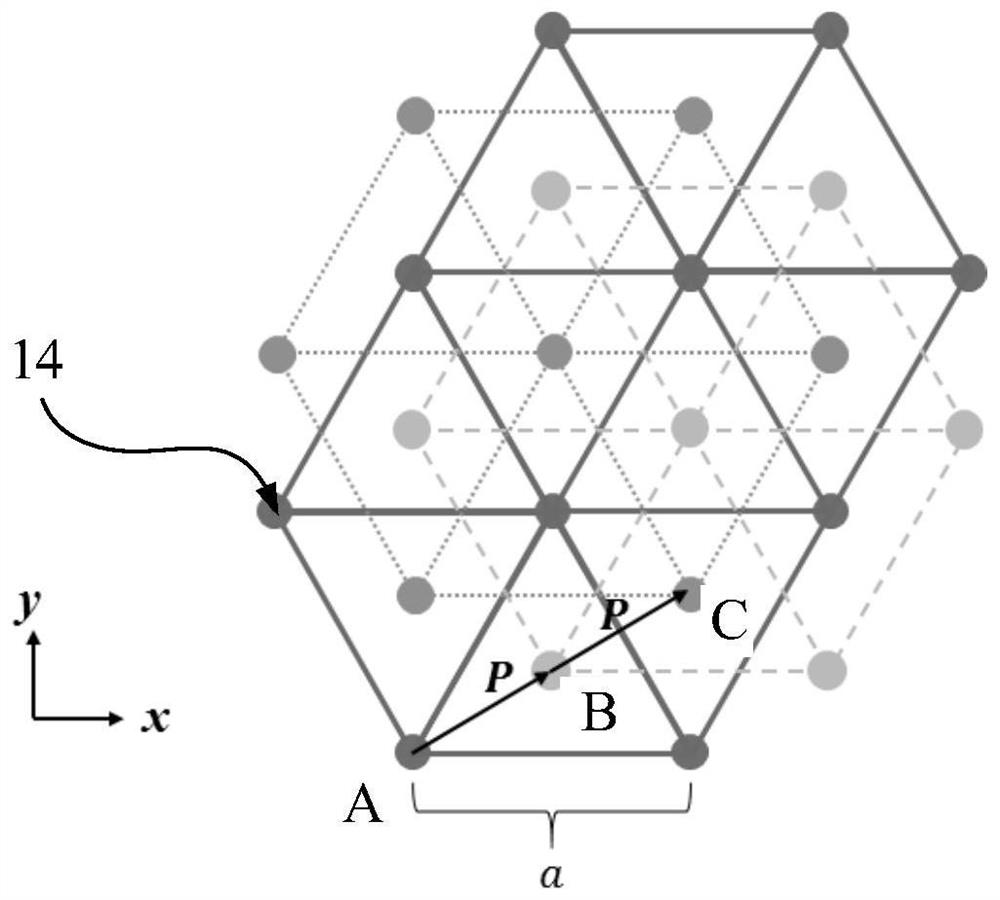

[0059] Through electron beam exposure combined with reactive ion beam etching technology, an array of holes arranged periodically in a triangular hexagonal structure is etched on the SOI wafer to obtain a base layer. Wherein, the distance between two adjacent holes is recorded as a, and the wavelength λ of the input optical signal is 1550nm, so it can be obtained that a=738nm, the aperture size is 0.88a, and the thickness of the SOI wafer is 0.82a.

[0060] When the three base layers are stacked together by wafer bonding technology, and when the hole array is etched on each silicon monolayer, the position of the hole array is relative to the upper layer, and there is one on the xy plane. image 3 The displacement along the vector P(0.5a, 0.29a) is shown, thus obtaining a periodic structure.

[0061] to combine Figure 4 , in the process of preparing the base layer, after selectively removing 5 rows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com