Numerical simulation method for inter-box flow of liquid metal cooled fast reactor

A liquid metal cooling and numerical simulation technology, applied in CAD numerical modeling, design optimization/simulation, etc., can solve problems such as low software calculation efficiency, poor convergence, and increased uncertainty in thermal and hydraulic analysis calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0159] The method of the present invention will be further described in detail below in conjunction with the specific embodiments of the accompanying drawings:

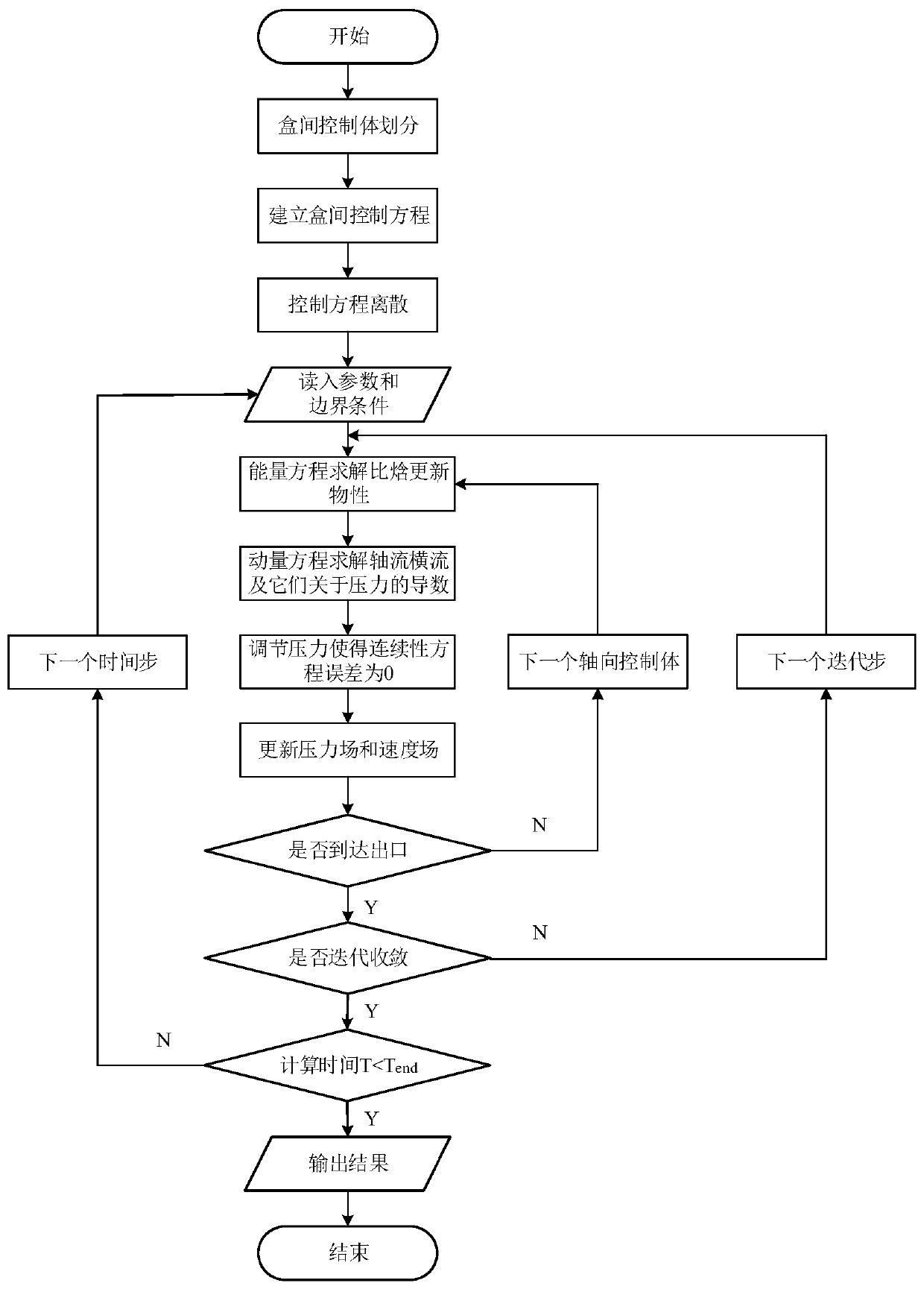

[0160] like figure 1 As shown, the present invention provides a numerical simulation method for flow between liquid metal cooling fast reactor core boxes, comprising the following steps:

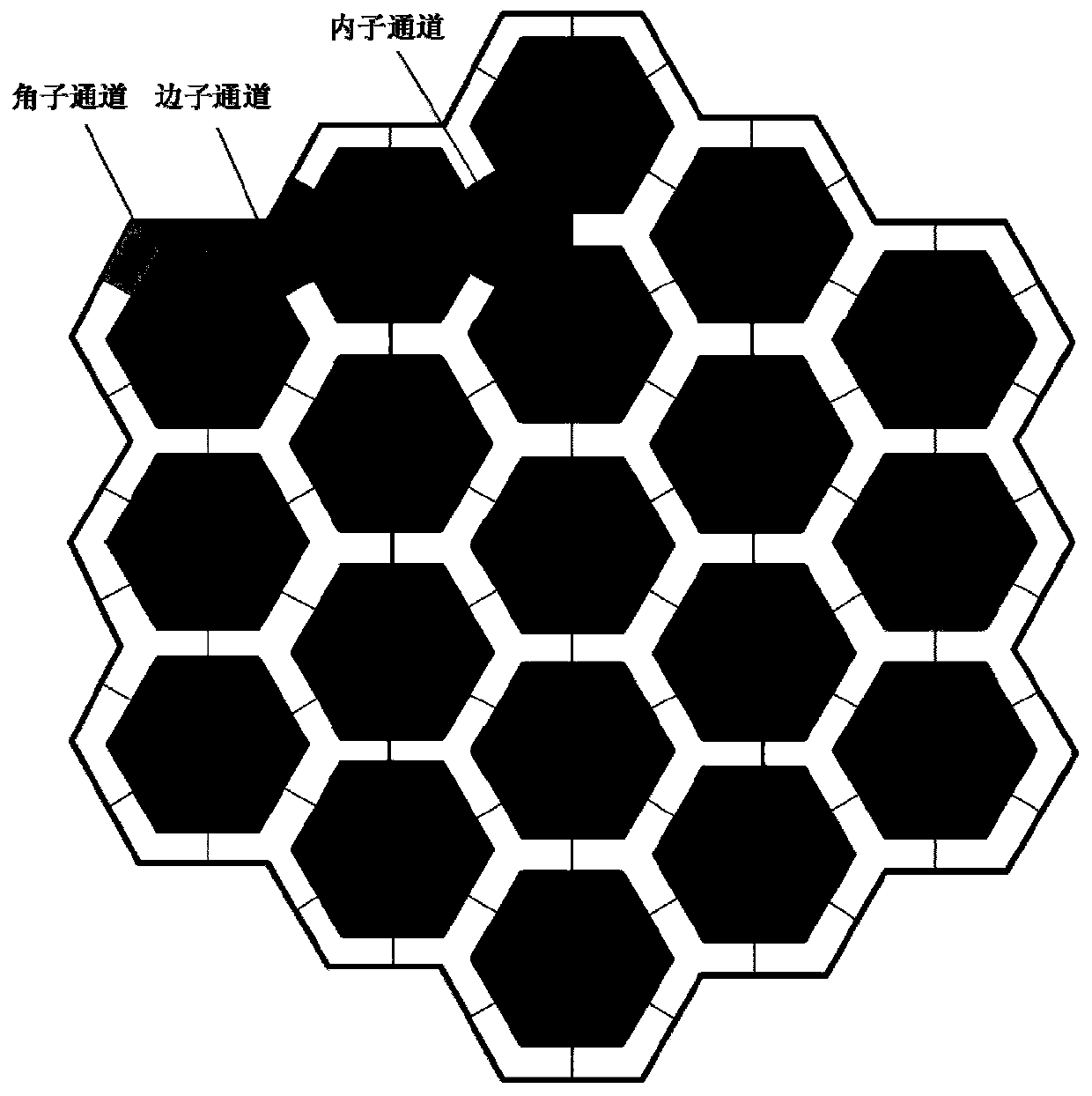

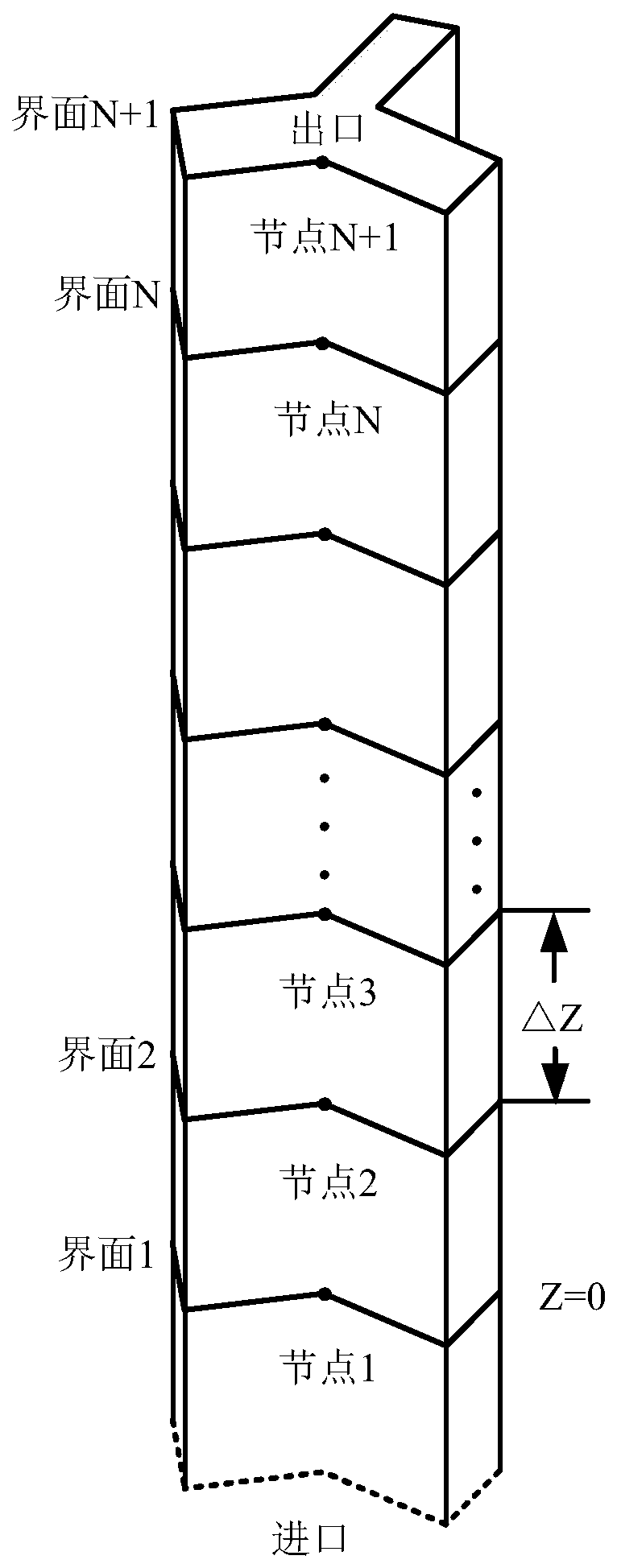

[0161] Step 1: The idea of sub-channels is adopted in the radial direction of the core to divide the control body for the channels between boxes, such as figure 2 As shown, the center of each component is connected radially, and the outermost ring component is perpendicular to the wall, and the inter-box channel is divided into three types: the inner sub-channel between the boxes, the side sub-channel between the boxes and the corner sub-channel between the boxes; the axial direction is along the The channel between boxes divides the control body with equal height or variable height, such as image 3 As shown in , the positions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com