Beef quality regulation and control method and beef product produced by same

A beef and quality technology, applied in the direction of food drying, food ingredients as taste improvers, food ingredients as taste improvers, etc., can solve the problems of difficult chewing, dark color, dry and hard texture, etc. Low energy consumption, improved dry and hard effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

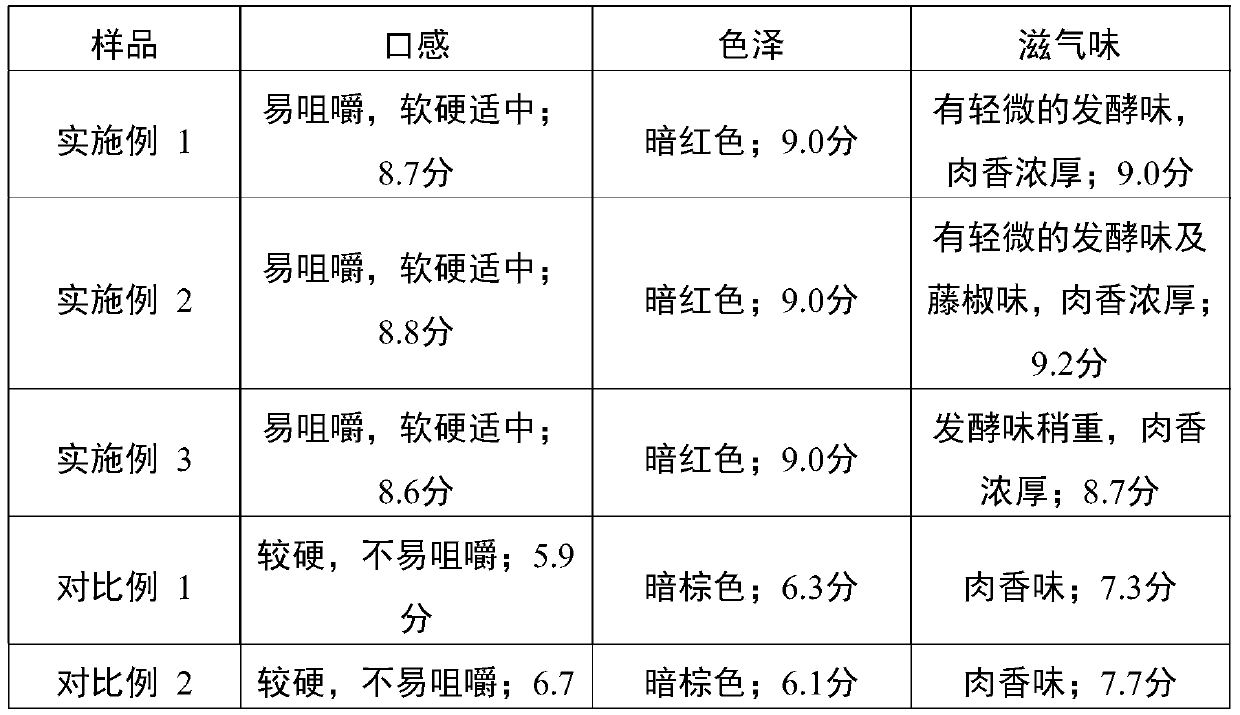

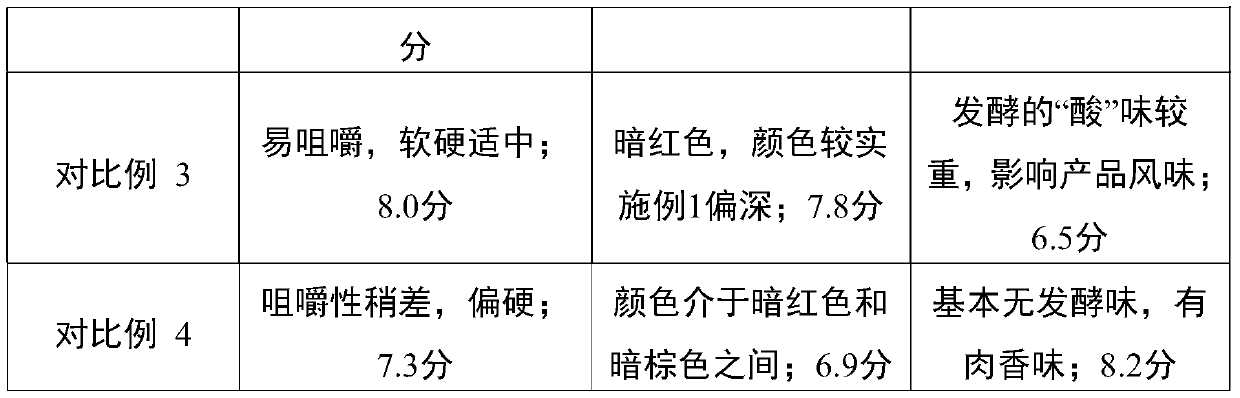

Examples

Embodiment 1

[0031] The present embodiment provides a kind of preparation method of beef strip product:

[0032] (1) Selection of raw meat: Select qualified frozen beef tenderloin and thaw it in a cold storage at 0-4°C.

[0033] (2) Trim and cut into strips: remove the fascia and fat on the surface of the raw meat at 10-12°C. According to product specifications, cut into long strips along the direction of muscle fibers.

[0034] (3) Pickling: After cleaning and disinfecting the fermentation room, pickle the beef strips evenly mixed with the marinade, the ambient temperature of the fermentation room is 20° C., and the pickling time is 48 hours. The marinade includes auxiliary materials and starters, wherein the starters include: 2.5×10 9 ~8×10 10 cfu / g Staphylococcus carnus and 3×10 10 ~9.8×10 10 cfu / g Staphylococcus bovis.

[0035] The auxiliary materials include table salt, trehalose, garlic powder, onion powder, cinnamon powder, and soy sauce. Based on the weight of raw meat, the ...

Embodiment 2

[0044] This example uses the same method as Example 1 to prepare beef strips, the difference is that rattan pepper powder and rattan pepper oil are added to the auxiliary materials of the marinade, and the added amount is 5% and 5% respectively based on the weight of raw meat. 50%.

Embodiment 3

[0046] In this example, beef strips were prepared using the same method as in Example 1, except that the curing conditions were as follows: the fermentation temperature was 18° C., and the curing time was 60 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com