Arc fuse curved surface additive posture modeling method and control method

A modeling method and surface technology, applied in the field of additive manufacturing, can solve the problems of less research, pose modeling and control, and no patent intellectual property rights or academic research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

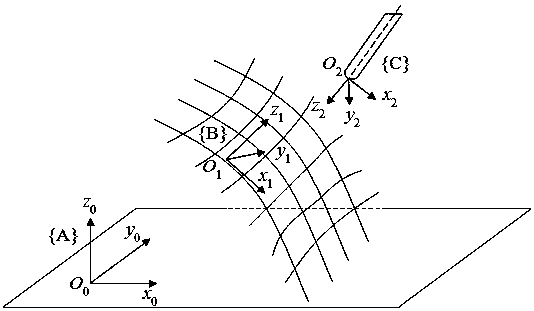

[0097] see figure 1 , an arc fuse surface additive pose modeling method, the modeling method includes the following steps:

[0098] S1. Establish workpiece coordinate system {A}, which is Cartesian coordinate system O 0 x 0 the y 0 z 0 ;

[0099] Among them, O 0 x 0 the y 0 The surface is a horizontal plane, O 0 point position and O 0 x 0 , O 0 the y 0 The direction of the workpiece is determined according to the simplest principle of workpiece positioning (the workpiece is positioned according to the point and direction specified by the user), O 0 z 0 The direction is opposite to the direction of gravity, and the workpiece coordinate system {A} satisfies the conditions of the right-hand rule; preferably, for the convenience of practical operation, O 0 x 0 , O 0 the y 0 The direction of the base coordinate system of the robot is consistent, and the origin is the feature point on the workpiece that is convenient for positioning;

[0100] S2. Establish the weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com