Assembling tool and method for accelerator cavity device of free electron laser device

A technology for laser device and assembly tooling, which is used in metal processing, metal processing equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] The present invention is described in detail below in conjunction with accompanying drawing:

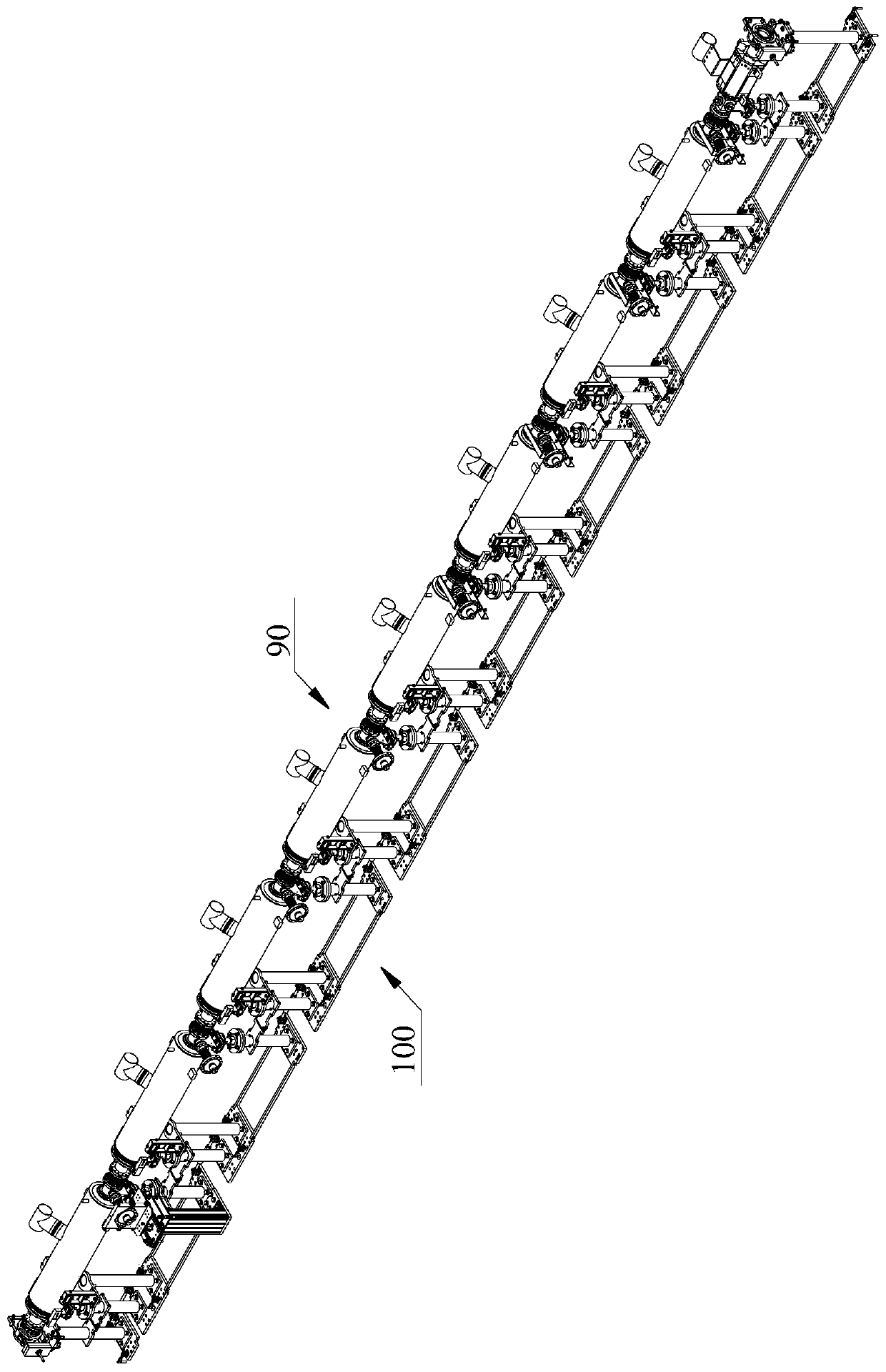

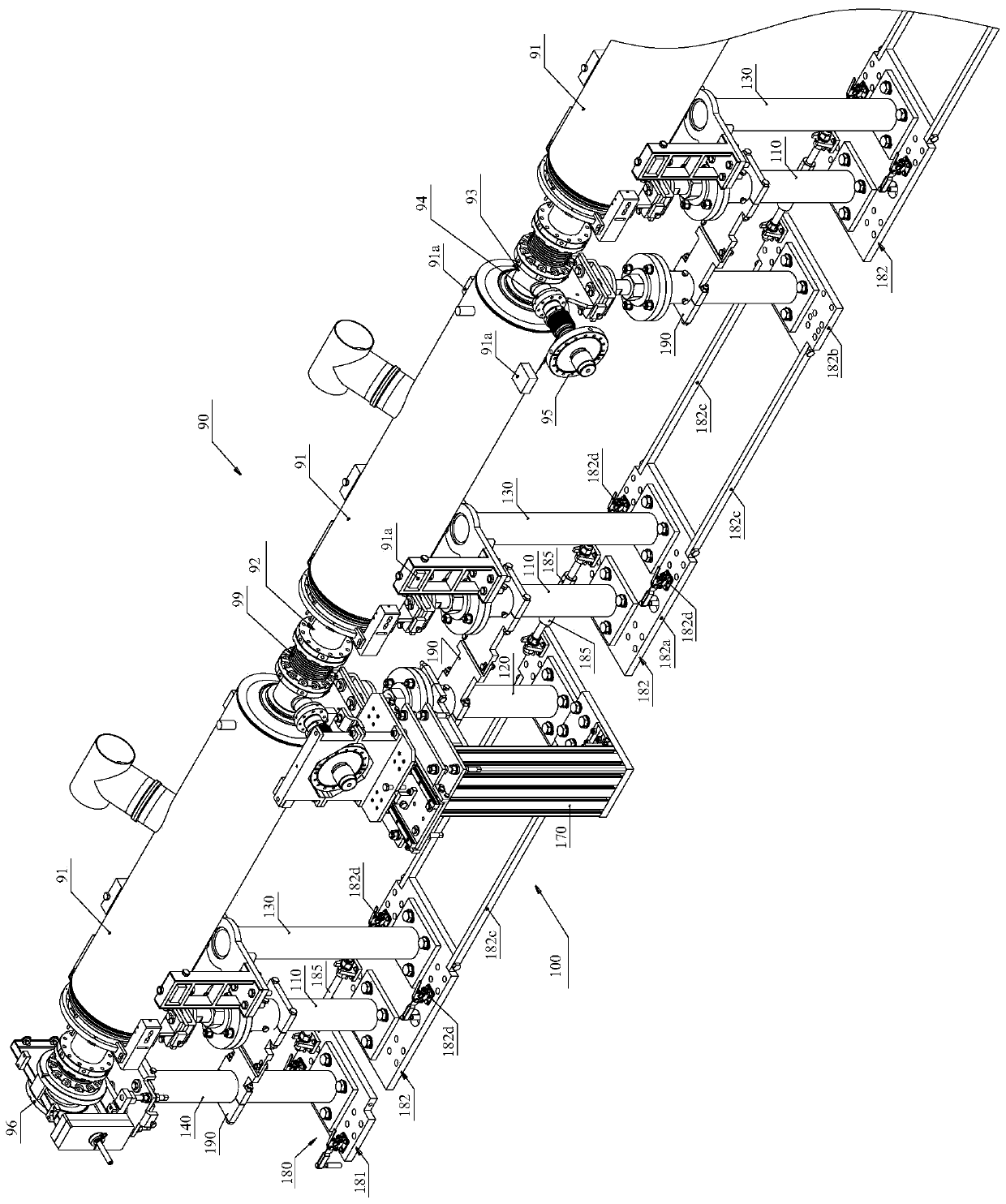

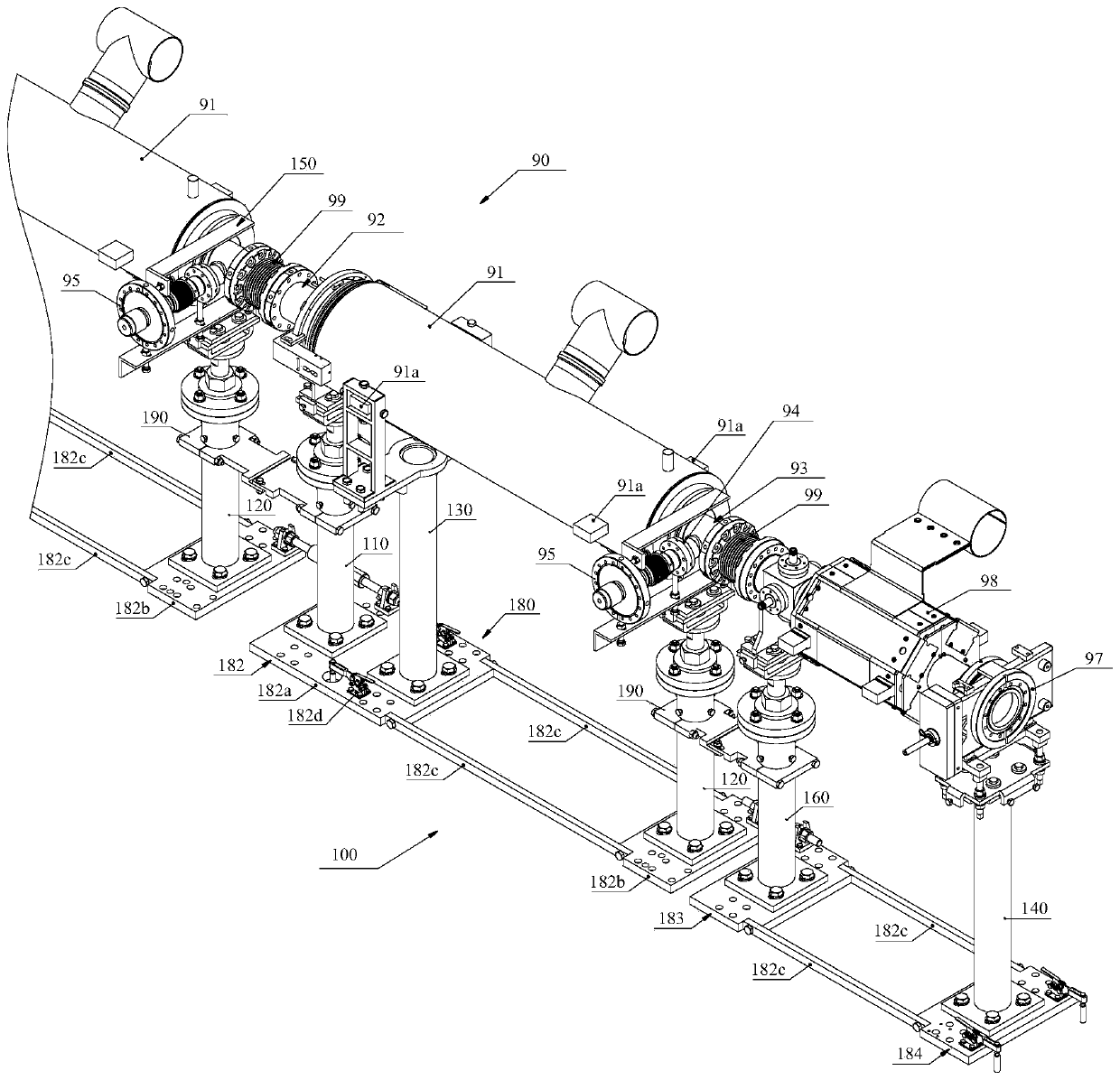

[0099] Please refer to Figure 1 to Figure 3 , the accelerator cavity device 90 of the free electron laser device includes an upstream valve 96 , a cavity string, a low temperature monitoring chamber 98 and a downstream valve 97 connected in sequence. Wherein the chamber string is formed by a plurality of segmental cavity bodies 91, and the adjacent segmental cavity bodies 91 are communicated by bellows 99, wherein the upstream valve 96 communicates with the adjacent segmental cavity bodies 91 by bellows 99, and the downstream valve 97 communicates with the adjacent segmental cavity bodies 91. Adjacent segment cavities 91 are communicated through vacuum tubes and bellows 99 , and a cryogenic monitoring chamber (BPM) 98 is sheathed on the vacuum tubes for monitoring electron beams passing through the accelerator cavity device 90 . The section cavity body 91 includes an upstrea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com