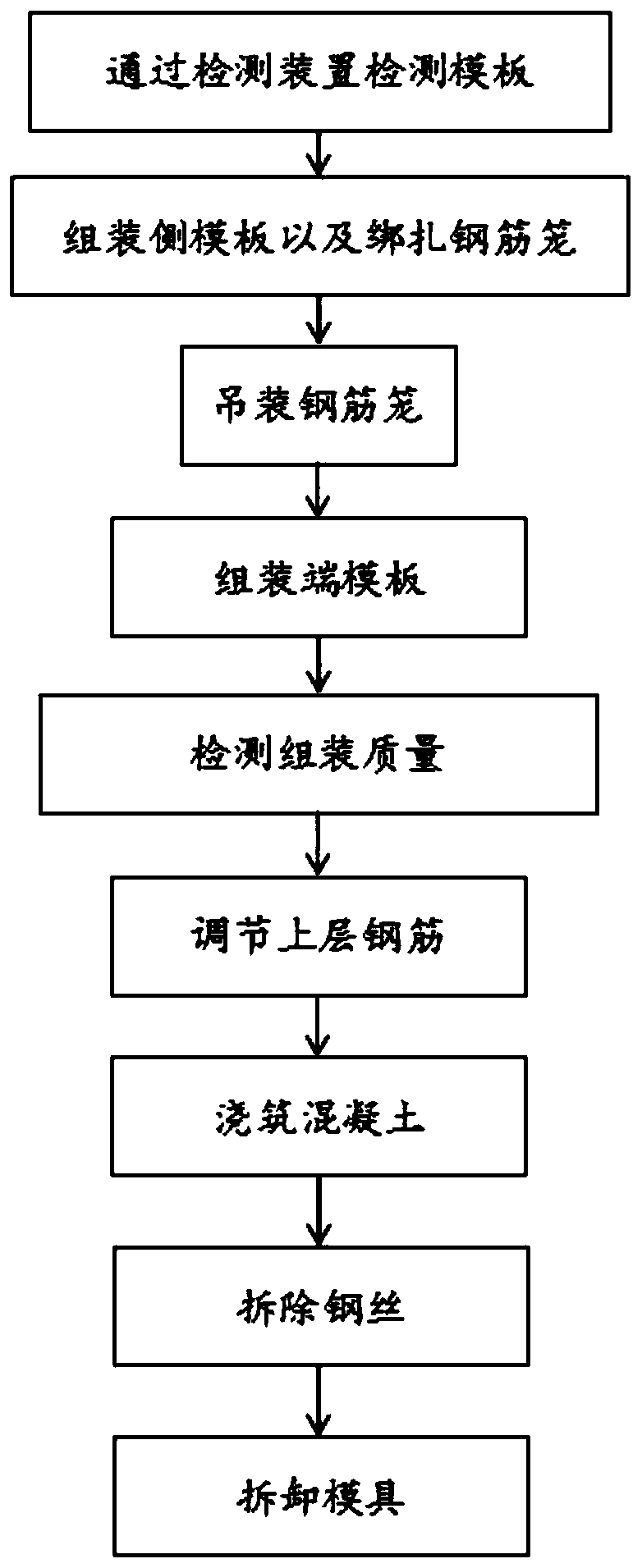

Manufacturing process of high-quality prefabricated column

A preparation process and prefabricated column technology, applied in manufacturing tools, columns, piers, etc., can solve the problems of oversized steel protective layer, structural instability, and unqualified component inspection and acceptance, and achieve reduced operation difficulty, convenient operation, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

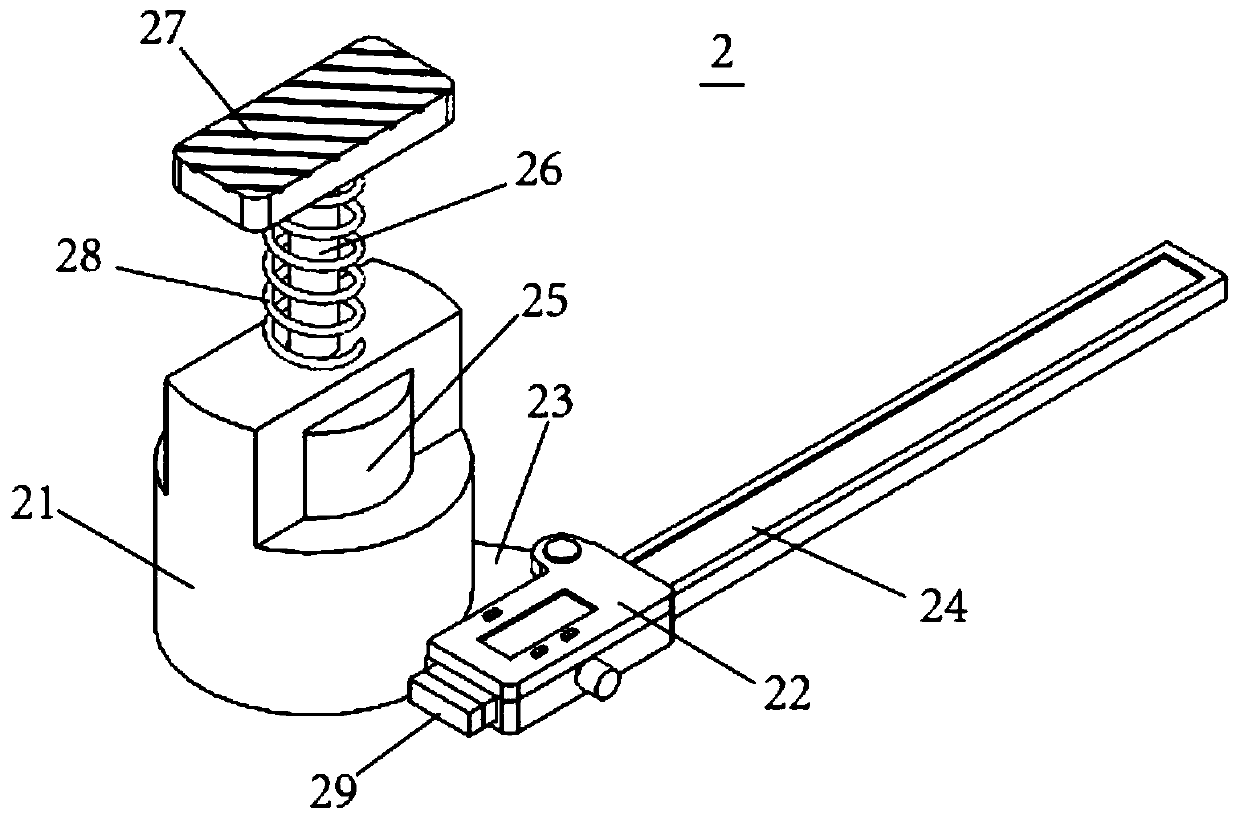

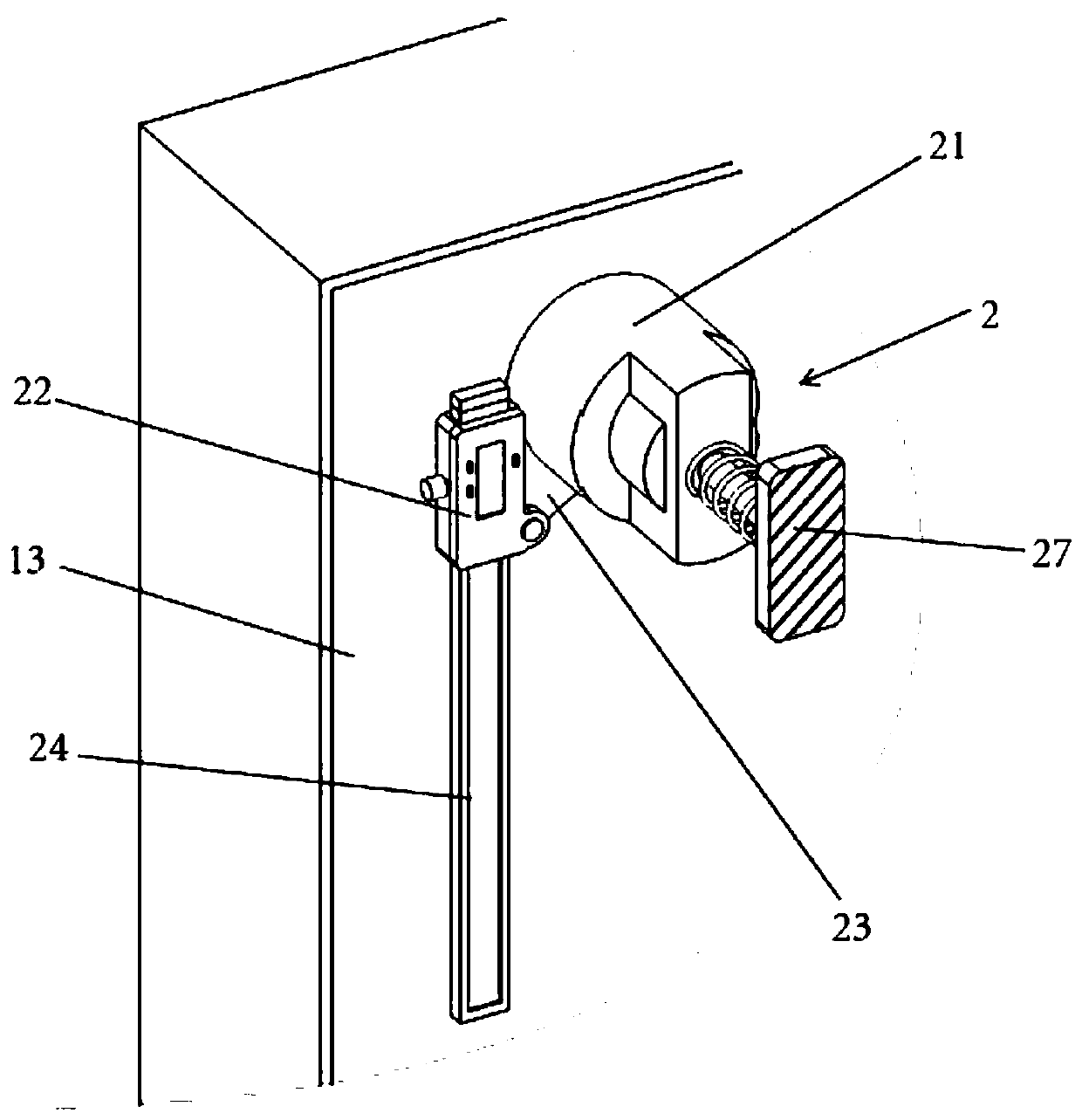

[0049] refer to Figure 1 to Figure 7 As shown, an embodiment of the high-quality prefabricated column preparation process of the present invention includes a mold platform 11 for building a mold 1, two side templates 12, two end templates 13 and at least four main ribs 14 for prefabrication (the main reinforcement includes the upper layer of reinforcement 15), some stirrups, and some sleeves 17. After the mold is set up, the grouting can be done after the installation of the main reinforcement, the stirrups and the sleeve, and the finished product can be obtained after curing.

[0050] In order to prepare high-quality prefabricated columns, the mold preparation drawings are quali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com