Extrusion system and extrusion method for harmless swill separation

A technology for separating swill and extrusion cavity, applied in the direction of presses, manufacturing tools, etc., can solve the problem of inability to adjust and control the moisture content of the extruded material, and achieve easy adjustment of the moisture content of the discharge material, high energy utilization, and extrusion. high feed efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

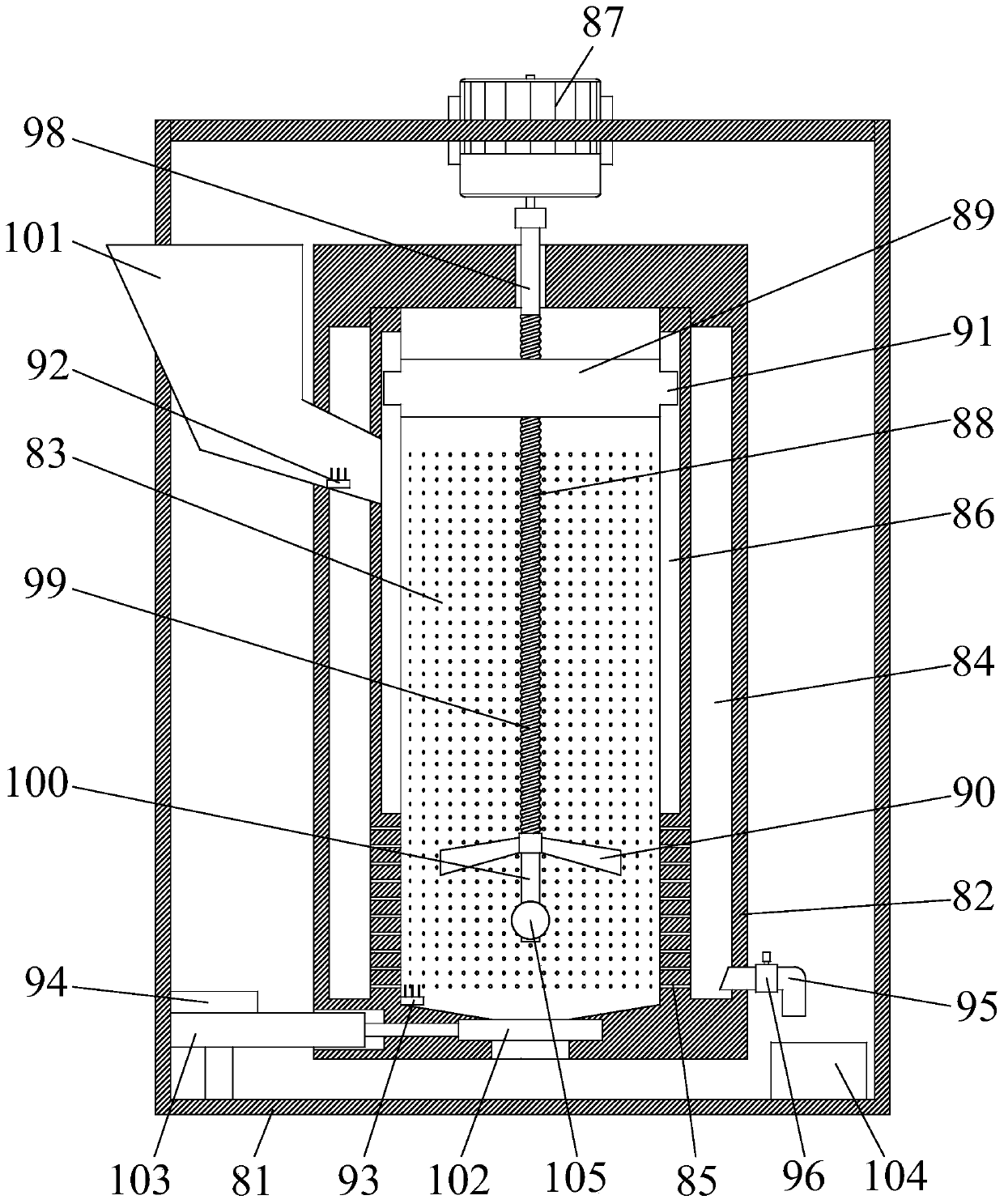

[0058] See figure 1 This embodiment provides an extrusion system for harmless separation of swill, and the extrusion system is used to squeeze the food experience. The extrusion system includes an extrusion frame 81, an extrusion shell 82, a feeding mechanism, an extrusion device, a detection device, an automatic discharging device, and an extrusion controller, and may also include a water storage tank 104.

[0059] The extrusion frame 81 is composed of a plurality of square tubes spliced, and the splicing method can be welding, clamping, screwing, etc., of course, it can also be integrally formed. The bottom end of the squeeze frame 81 can be provided with a structure such as a pulley to facilitate the squeeze frame 81 to move on the ground. At the same time, the bottom of the extrusion frame 81 can also be provided with a limiting structure, which can limit the movement of the extrusion frame 81 on the ground, and ensure that the extrusion frame 81 is stably placed in a desired...

Embodiment 2

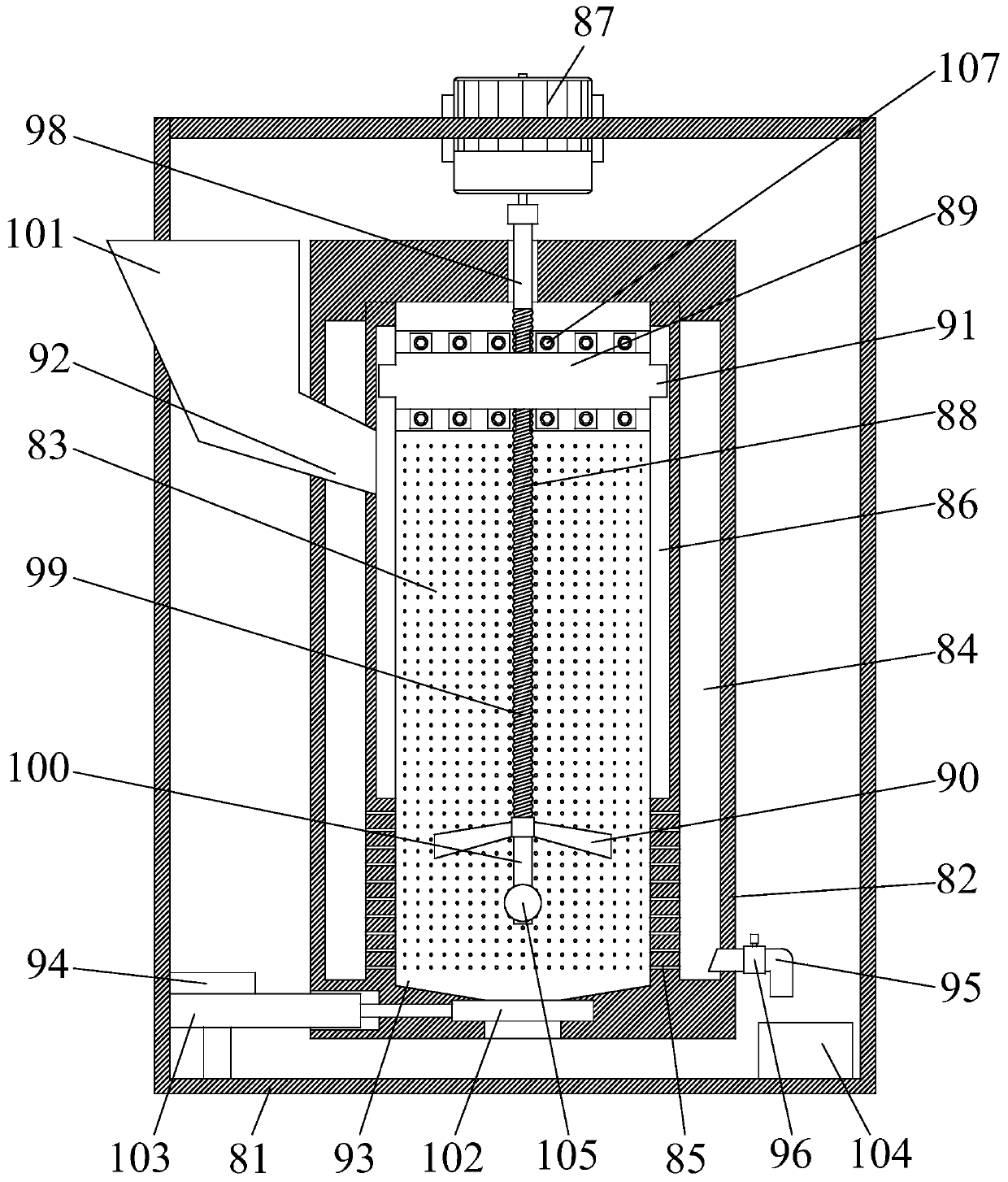

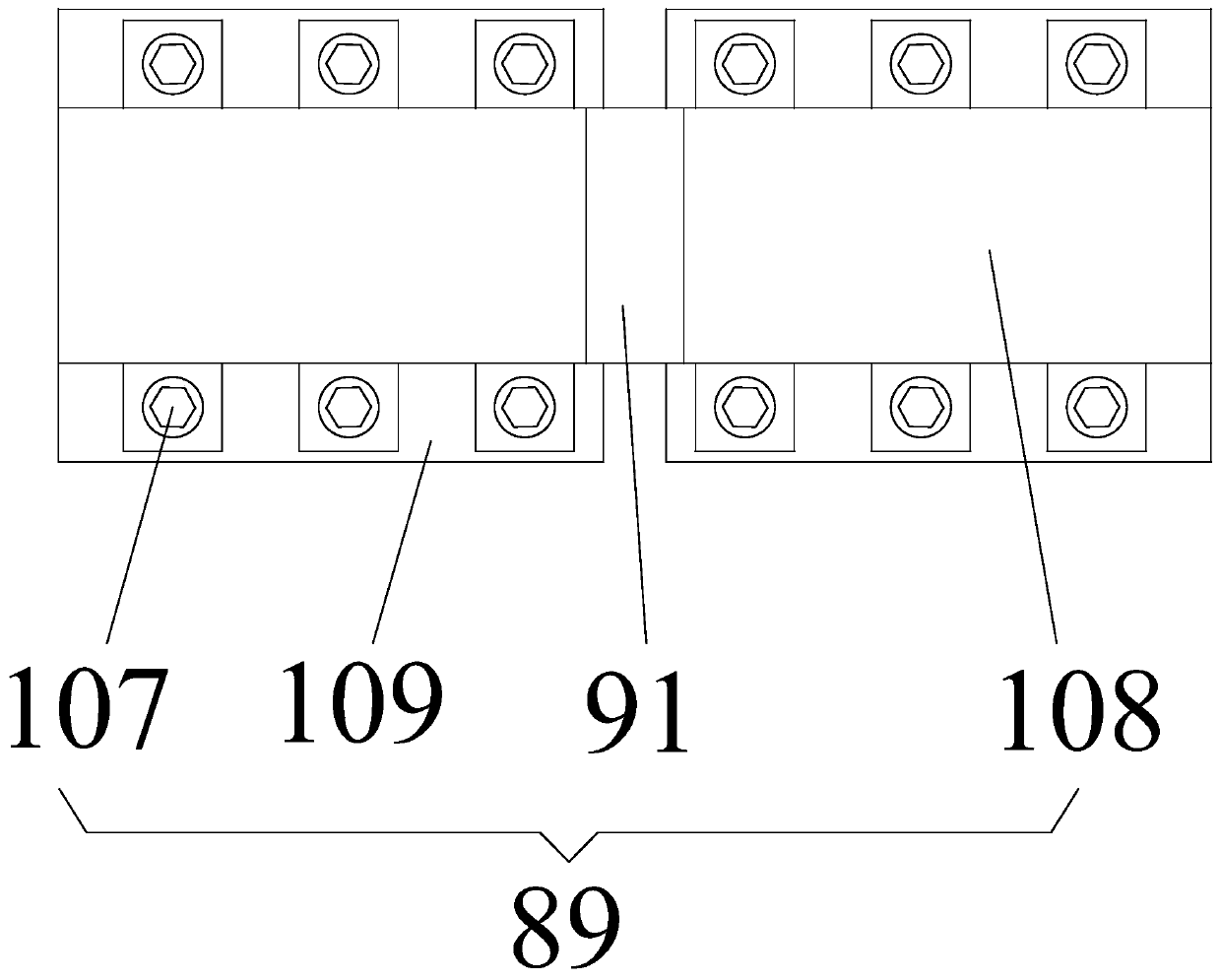

[0072] See figure 2 , image 3 as well as Figure 4 This embodiment provides an extrusion system for harmless separation of swill. The extrusion system is similar to that of Example 1, except that the extrusion block 89 is a detachable structure, which is detachably connected to the stud 88 on. Among them, the extrusion block 89 includes a bolt 107 and two extrusion components. The number of bolts 107 is multiple, and the two extrusion components are detachably connected by multiple bolts 107. Each extrusion assembly includes a semicircular block 108 and two sets of mounting bars 109. The two sets of mounting bars 109 are respectively fixed on the two circular surfaces of the semicircular block 108. The mounting bars 109 on the surfaces of different semicircular blocks 108 are fixed by a plurality of bolts 107, so that the two semicircular blocks 108 are spliced into a round cake structure. In this way, when the extrusion block 89 needs to be disassembled, the two semicirc...

Embodiment 3

[0074] See Figure 5 This embodiment provides an extrusion system for harmless separation of swill. The extrusion system adds a liquid level sensor 97 on the basis of the first embodiment. The liquid level sensor 97 is a detection device and is installed in the water storage space 84 and used to detect the liquid level of the liquid in the water storage space 84. The squeeze controller is used to determine whether the liquid level is greater than a preset liquid level. When the liquid level is greater than the preset liquid level, the squeeze controller drives the liquid outlet switch 96 to open so that the liquid in the water storage space 84 is discharged.

[0075] The squeeze system for the harmless separation of swill, the liquid level sensor can detect the liquid level in the water storage space, and the squeeze controller will drive the liquid outlet switch to open when the detected liquid level is greater than the preset liquid level. , In order to discharge the liquid in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com