Damping mechanism for bobbin winder

A shock-absorbing mechanism and winding machine technology, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve problems such as large vibration, achieve low cost, improve the mechanical characteristics of the drum, and prolong the structural cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

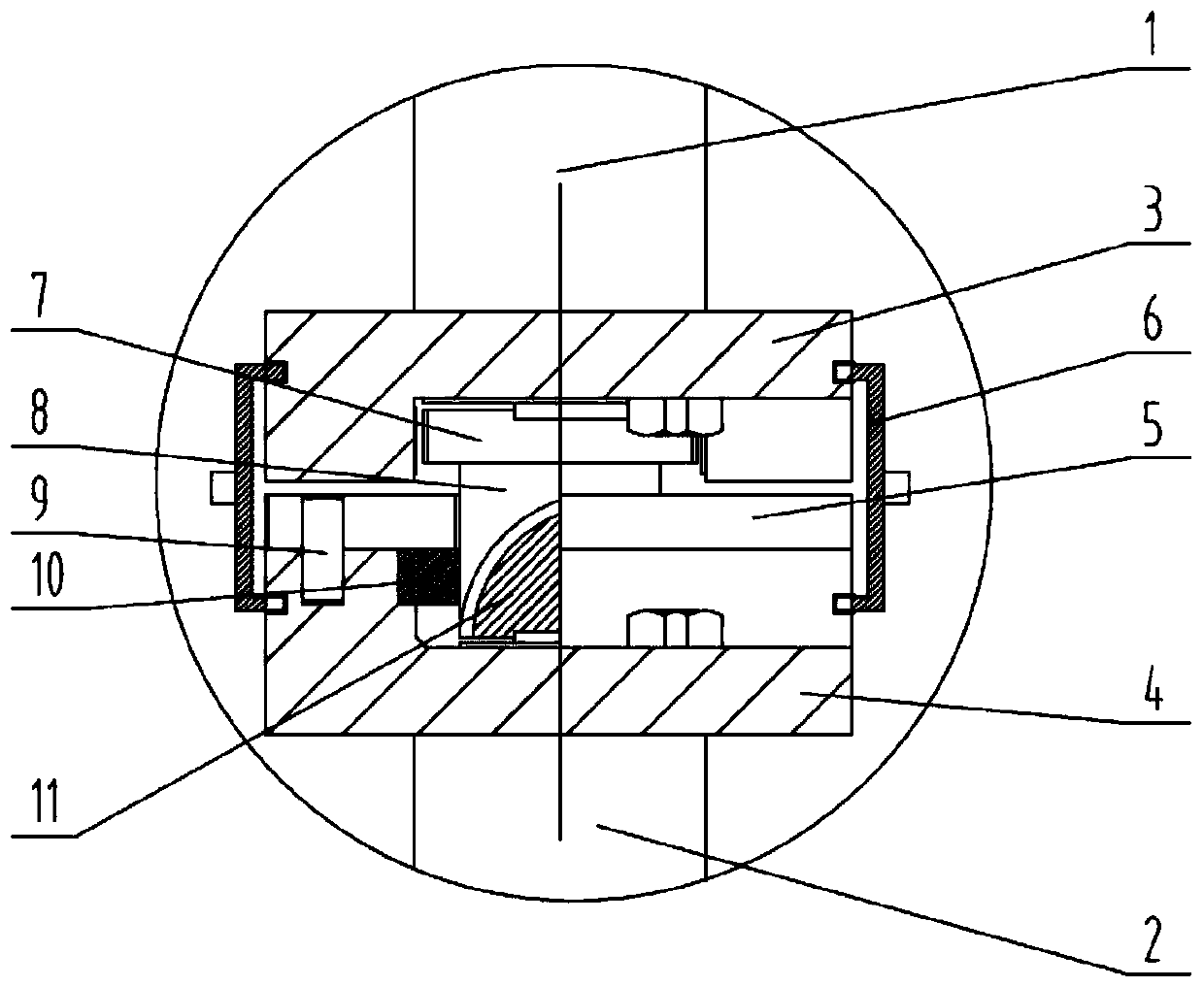

[0022] Implementation case 1: The shock absorbing mechanism for the winder includes the main body and the drum 1, the drum frame 2 is arranged at the lower end of the drum 1, and the shock absorbing assembly is arranged between the drum 1 and the drum frame 2, and the shock absorbing assembly includes an upper shock absorbing sleeve 3 and the lower shock-absorbing sleeve 4, between the upper shock-absorbing sleeve 3 and the lower shock-absorbing sleeve 4, an upper shock-absorbing plate 7, a spherical slide plate 8, a spherical bearing 11 and a lower shock-absorbing plate are sequentially arranged from top to bottom. The vibration plate, the spherical bearing 11 is a hemispherical structure, the spherical bearing 11 is slidingly connected with the spherical slide 8, the hard shear ring 5 is set on the outer side of the spherical slide 8, and the hard shear ring 5 is connected with the lower The part of the shock absorbing sleeve 4 is provided with a highly elastic damping ring 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com