A kind of printed steel plate and preparation method thereof

A steel plate and printing technology, which is applied in the field of printed steel plate and its preparation, can solve the problems of poor wear resistance and environmental corrosion resistance, and achieve the effects of improving hydrophobicity, self-cleaning performance, and environmental corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

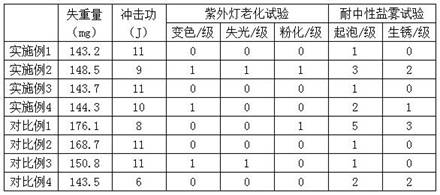

Examples

Embodiment 1

[0070] A printed steel plate, comprising successively bonded hot-dip galvanized steel sheet layers, a primer layer, a transfer printing ink layer, an adhesive layer and a topcoat layer, the materials for the topcoat layer include the following raw materials in parts by weight:

[0071] 25 parts polyvinylidene fluoride

[0072] 0.4 parts of polyamide wax

[0073] Fluorocarbon surfactant 0.02 part

[0074] Carbon nanotube 0.5 part

[0075] Solvent A 55 parts.

[0076] The fluorocarbon surfactant is formed by mixing anionic fluorosurfactant and nonionic fluorosurfactant at a weight ratio of 4:1.

[0077] The anionic fluorosurfactant is DuPont FSA, and the nonionic fluorosurfactant is DuPont FSO.

[0078] The carbon nanotubes have a diameter of 55 nm and a length of 1.2 μm.

[0079] The solvent A is formed by mixing dimethylacetamide and N-methyl-2-pyrrolidone in a weight ratio of 4:2.

[0080] The preparation method of the material of described top coat layer comprises the ...

Embodiment 2

[0124] A printed steel plate, comprising successively bonded hot-dip galvanized steel sheet layers, a primer layer, a transfer printing ink layer, an adhesive layer and a topcoat layer, the materials for the topcoat layer include the following raw materials in parts by weight:

[0125] 20 parts polyvinylidene fluoride

[0126] 0.2 parts of polyamide wax

[0127] Fluorocarbon surfactant 0.003 parts

[0128] Carbon nanotube 0.2 parts

[0129] Solvent A 50 parts.

[0130] The fluorocarbon surfactant is formed by mixing anionic fluorosurfactant and nonionic fluorosurfactant at a weight ratio of 3:1.

[0131] The anionic fluorosurfactant is a mixture of FS-62 and FSE in a weight ratio of 2:1, and the nonionic fluorosurfactant is a mixture of FSN-100 and FS-300 in a weight ratio of 3:2 made.

[0132] The carbon nanotubes have a diameter of 30 nm and a length of 0.5 μm.

[0133] The solvent A is formed by mixing dimethylacetamide and N-methyl-2-pyrrolidone in a weight ratio of ...

Embodiment 3

[0178] A printed steel plate, comprising successively bonded hot-dip galvanized steel sheet layers, a primer layer, a transfer printing ink layer, an adhesive layer and a topcoat layer, the materials for the topcoat layer include the following raw materials in parts by weight:

[0179] 30 parts polyvinylidene fluoride

[0180] 0.6 parts of polyamide wax

[0181] Fluorocarbon surfactant 0.03 parts

[0182] 0.8 parts of carbon nanotubes

[0183] Solvent A 60 parts.

[0184] The fluorocarbon surfactant is formed by mixing anionic fluorosurfactant and nonionic fluorosurfactant at a weight ratio of 5:1.

[0185] The anionic fluorosurfactant is FBS, and the nonionic fluorosurfactant is FSN-100.

[0186] The carbon nanotubes have a diameter of 80 nm and a length of 2 μm.

[0187] The solvent A is formed by mixing dimethylacetamide and N-methyl-2-pyrrolidone in a weight ratio of 5:2.

[0188] The preparation method of the material of described top coat layer comprises the steps: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com