Antibacterial, mildew-proof and mothproof rice paper virginal pulp, prepared rice paper and preparation method

An antibacterial, anti-mildew, and anti-moth-eaten technology, which is applied in the field of rice paper manufacturing, can solve the problems of rice paper with less anti-bacterial, anti-mildew, and anti-insect moths, which is not conducive to large-scale production, and the preparation process is cumbersome.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a method for preparing antibacterial, mildew-proof and insect-proof rice paper. The preparation method specifically includes the following steps:

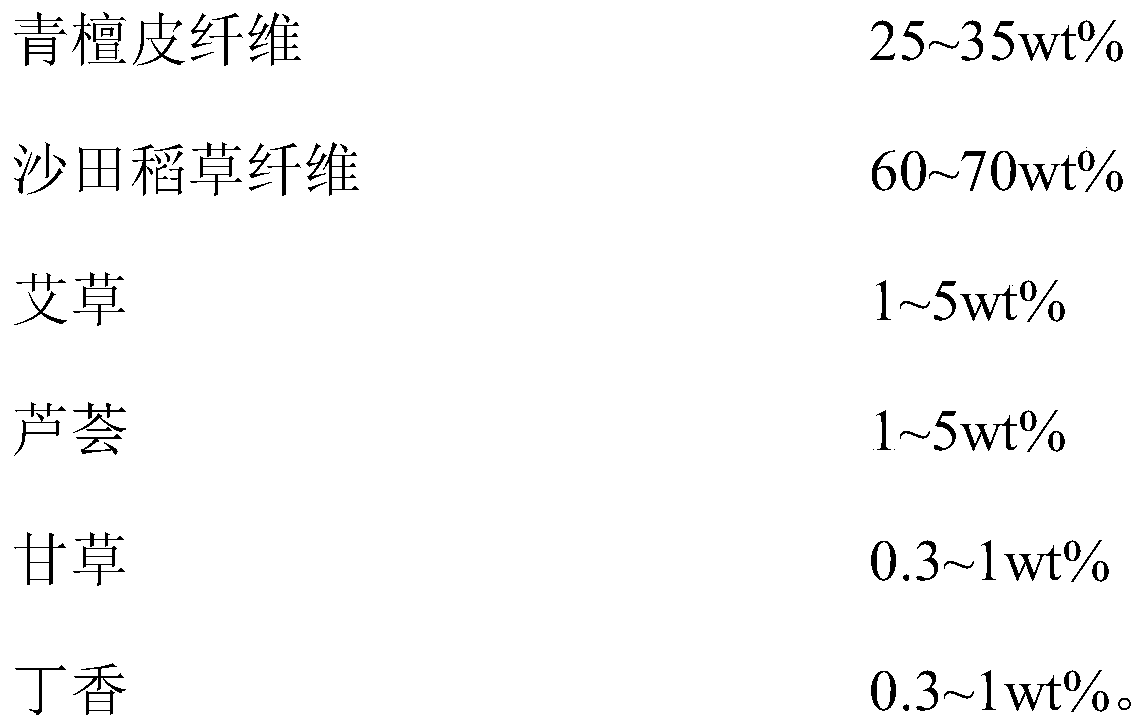

[0037] (1) mixing green sandalwood bark fiber, sandalwood straw fiber, mugwort, aloe, licorice and cloves by the following mass percentages to obtain the original pulp of rice paper;

[0038]

[0039] (2) The rice paper raw pulp obtained in step (1) is successively prepared to obtain the described rice paper through scooping, squeezing, drying and drying, and adding 2wt% chitosan to the scooping liquid in the scooping process Sugar acetic acid solution, the added chitosan acetic acid solution accounts for 0.8wt% of the original pulp of rice paper.

[0040] See Table 1 for a summary of the distribution ratio of each component in the rice paper puree prepared in each embodiment and the concentration and addition amount of the chitosan acetic acid solution in the paper scooping liquid.

[0041] The ...

Embodiment 2

[0043] This embodiment provides a method for preparing antibacterial, mildew-proof and insect-proof rice paper. The preparation method specifically includes the following steps:

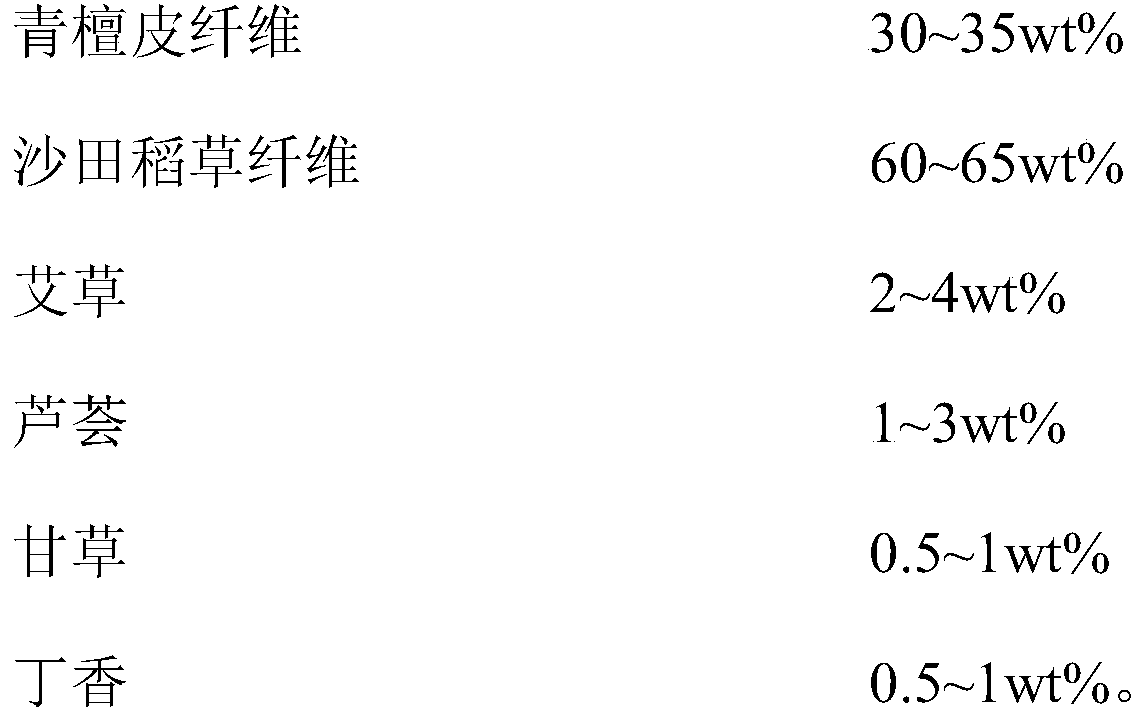

[0044] (1) mixing green sandalwood bark fiber, sandalwood straw fiber, mugwort, aloe, licorice and cloves by the following mass percentages to obtain the original pulp of rice paper;

[0045]

[0046] (2) The rice paper raw pulp obtained in step (1) is successively prepared to obtain the described rice paper through scooping, squeezing, drying and drying, and adding 2wt% chitosan to the scooping liquid in the scooping process Sugar acetic acid solution, the added chitosan acetic acid solution accounts for 0.6wt% of the original pulp of rice paper.

[0047] See Table 1 for a summary of the distribution ratio of each component in the rice paper puree prepared in each embodiment and the concentration and addition amount of the chitosan acetic acid solution in the paper scooping liquid.

[0048] The ...

Embodiment 3

[0050] This embodiment provides a method for preparing antibacterial, mildew-proof and insect-proof rice paper. The preparation method specifically includes the following steps:

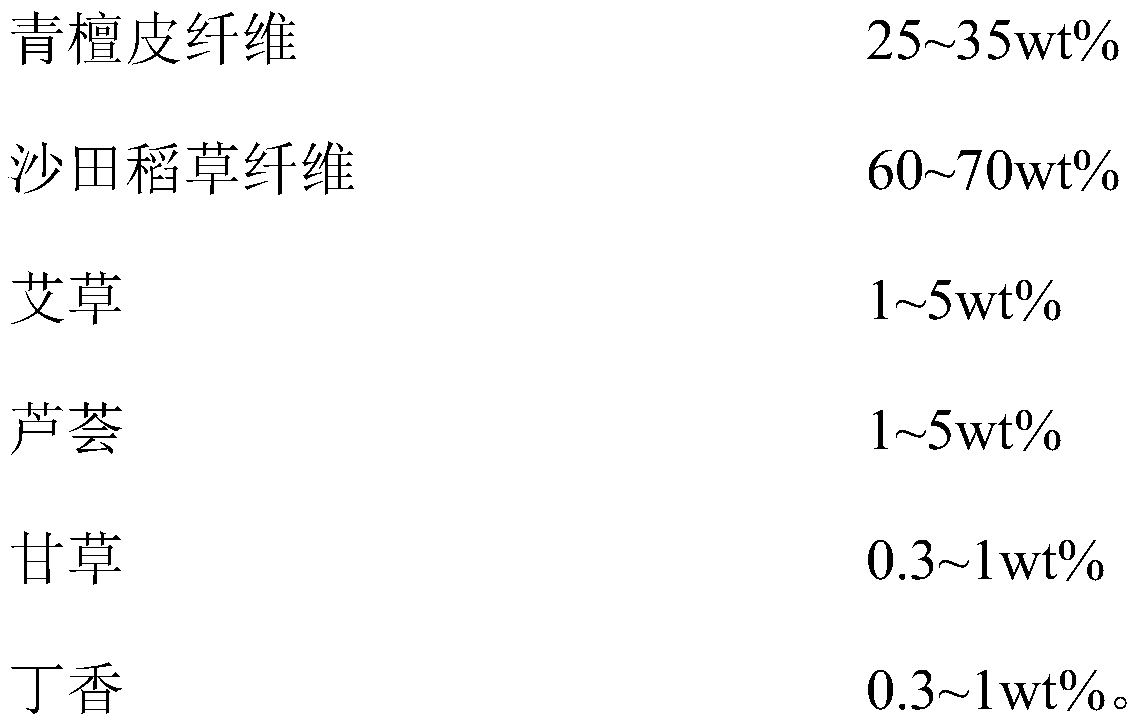

[0051] (1) mixing green sandalwood bark fiber, sandalwood straw fiber, mugwort, aloe, licorice and cloves by the following mass percentages to obtain the original pulp of rice paper;

[0052]

[0053]

[0054] (2) The rice paper raw pulp obtained in step (1) is successively prepared to obtain the described rice paper through scooping, squeezing, drying and drying, and adding 2wt% chitosan to the scooping liquid in the scooping process Sugar acetic acid solution, the added chitosan acetic acid solution accounts for 0.5wt% of the original pulp of rice paper.

[0055] See Table 1 for a summary of the distribution ratio of each component in the rice paper puree prepared in each embodiment and the concentration and addition amount of the chitosan acetic acid solution in the paper scooping liquid.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com