Composite material for liquid medicine packaging bag

A composite material and packaging bag technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of short shelf life, no antibacterial and anti-mildew effect, not durable, etc., and achieve the effect of increasing shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

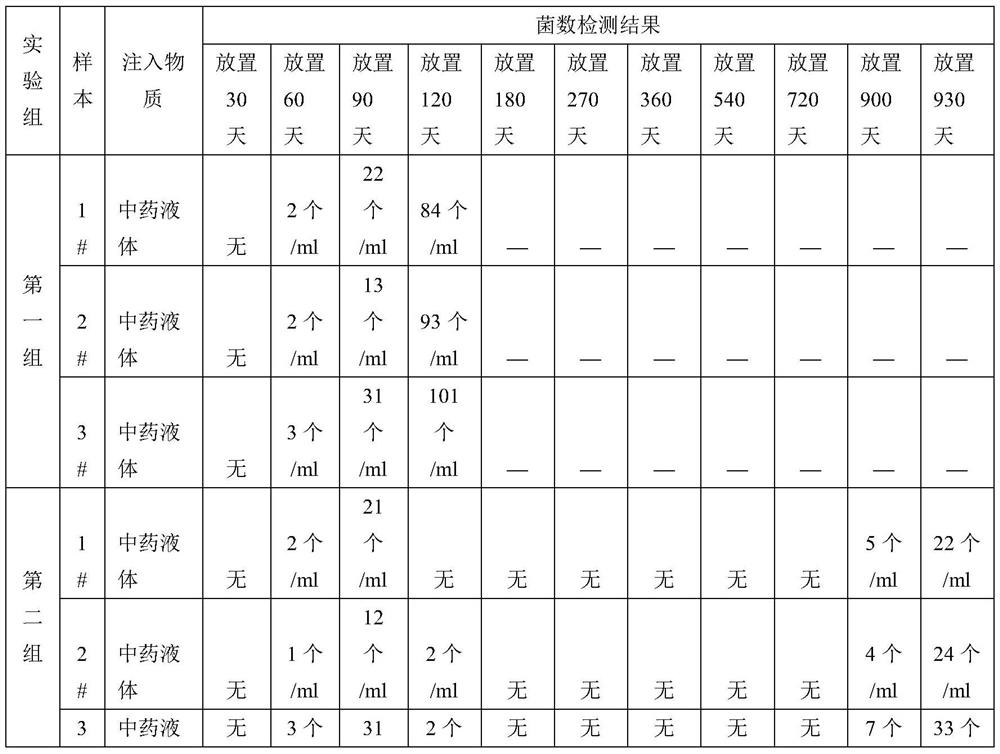

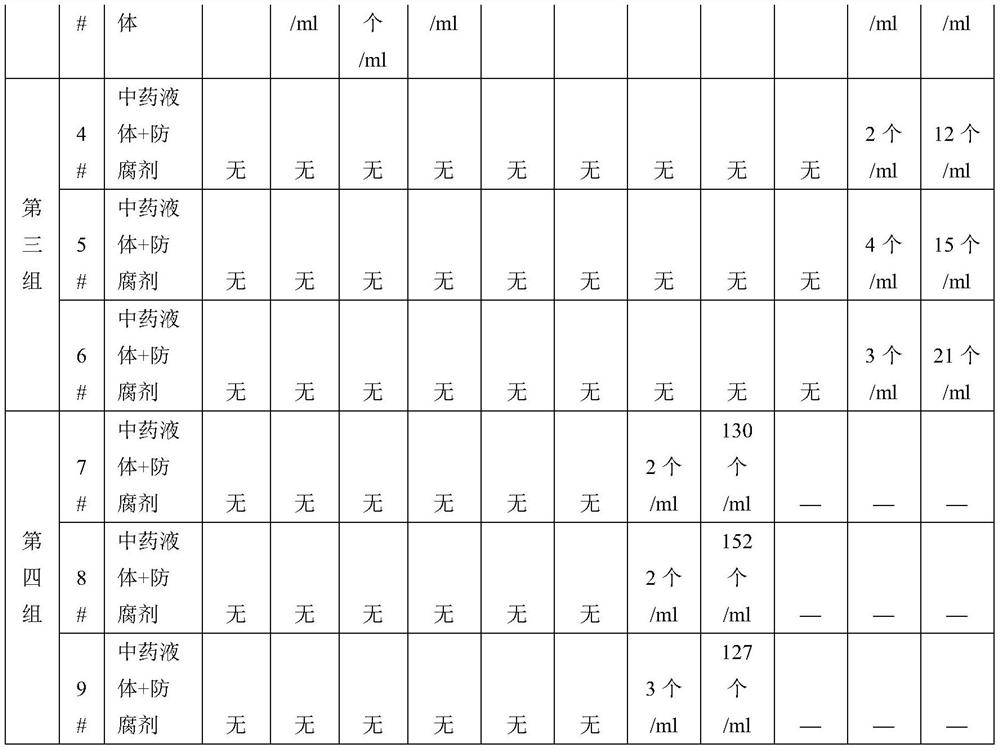

Examples

Embodiment 1

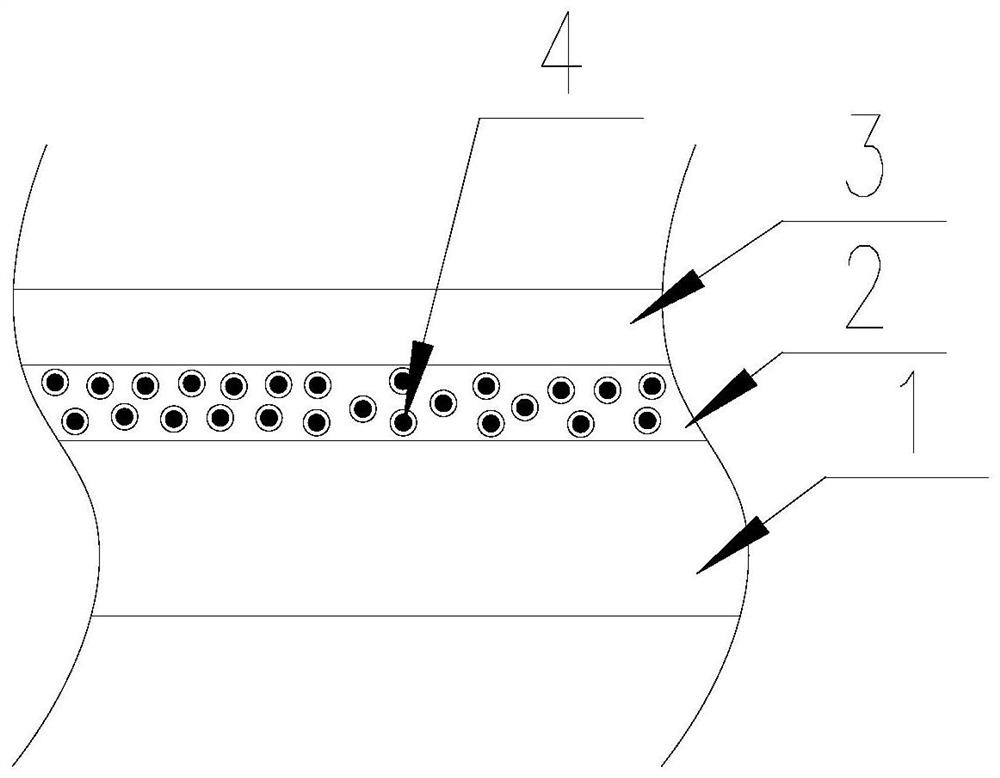

[0036] like figure 1 As shown, a composite material for a liquid medicine packaging bag is composed of a barrier layer, an antibacterial layer, and a waterproof and breathable layer from the outer layer to the inner layer. The antibacterial layer includes an antibacterial material and a viscose material. The antibacterial material is silver and The composite of PLGA, the viscose material is polyurethane, and the material of the waterproof breathable layer is PE.

[0037] The mass ratio of EVOH and LDPE is 3:1.

[0038] EVOH and LDPE are prepared by conventional co-extrusion method.

[0039] The specific form of the antibacterial layer is: nano silver powder and PLGA are evenly mixed into the viscose layer.

[0040] The specific preparation method is: dissolve PLGA in dichloromethane to form a PLGA solution, add nano-silver powder under stirring conditions and stir evenly, then stir at a low speed until the dichloromethane is completely volatilized to obtain a uniformly mixed...

Embodiment 2

[0048] The difference between this embodiment and Example 1 is that the specific form of the antibacterial material is: silver is the core, PLGA is the microsphere of the shell, the microspheres are distributed in the viscose material, and the shell of PLGA can Nano-silver package, in the early stage, before PLGA is degraded, nano-silver cannot be released. At this time, it can be antibacterial and anti-mildew by the sterilized packaging material or the anti-fungal agent in the drug itself, and as the water vapor in the liquid drug enters To the antibacterial layer, the PLGA shell is degraded until the nano-silver is released, thereby supplementing the antibacterial and antifungal properties of the drug.

[0049] The antibacterial material is prepared by a microemulsion method.

[0050] Specifically, nano-silver is added to the PLGA solution, and is emulsified into microspheres under the stirring condition of a high-pressure homogenizer, and the solution of the PLGA is that PL...

Embodiment 3

[0054] Embodiment 3 The difference between this embodiment and Embodiment 1 is that the mass ratio of EVOH and LDPE is 2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com