Graphene modified ink and preparation method thereof

A graphene modification and graphene technology, applied in ink, household utensils, applications, etc., can solve the problems of phenol harm to human body, fragrance volatilization, loss of ink flavor, etc., and achieve good antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

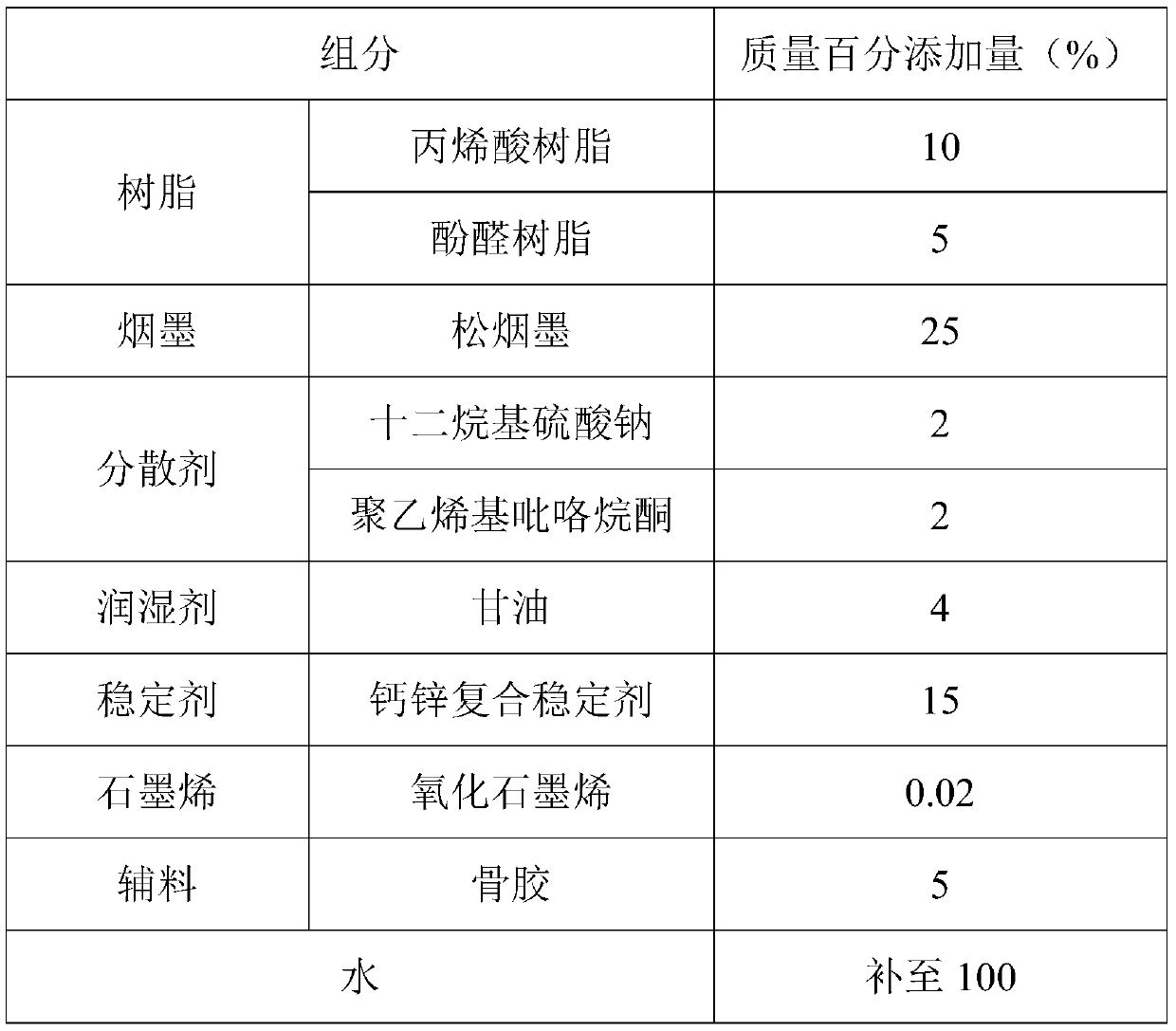

[0058] This embodiment provides a kind of graphene modified ink, the preparation raw material of described graphene modified ink comprises the following components by mass percentage:

[0059]

[0060] The preparation method of graphene modified ink described in the present embodiment comprises the following steps:

[0061] (1) The above resin (acrylic resin and phenolic resin), pine smoke ink, dispersant (sodium lauryl sulfate and polyvinylpyrrolidone), wetting agent (glycerin), graphene oxide, bone glue and After mixing with water for 35 minutes, place it in a ball mill and grind for 40 minutes to obtain a mixed slurry;

[0062] (2) After mixing the mixed slurry obtained in step (1) with a stabilizer (calcium-zinc composite stabilizer) for 15 minutes, sieve with a 200-mesh sieve with an aperture to obtain the graphene-modified ink.

Embodiment 2

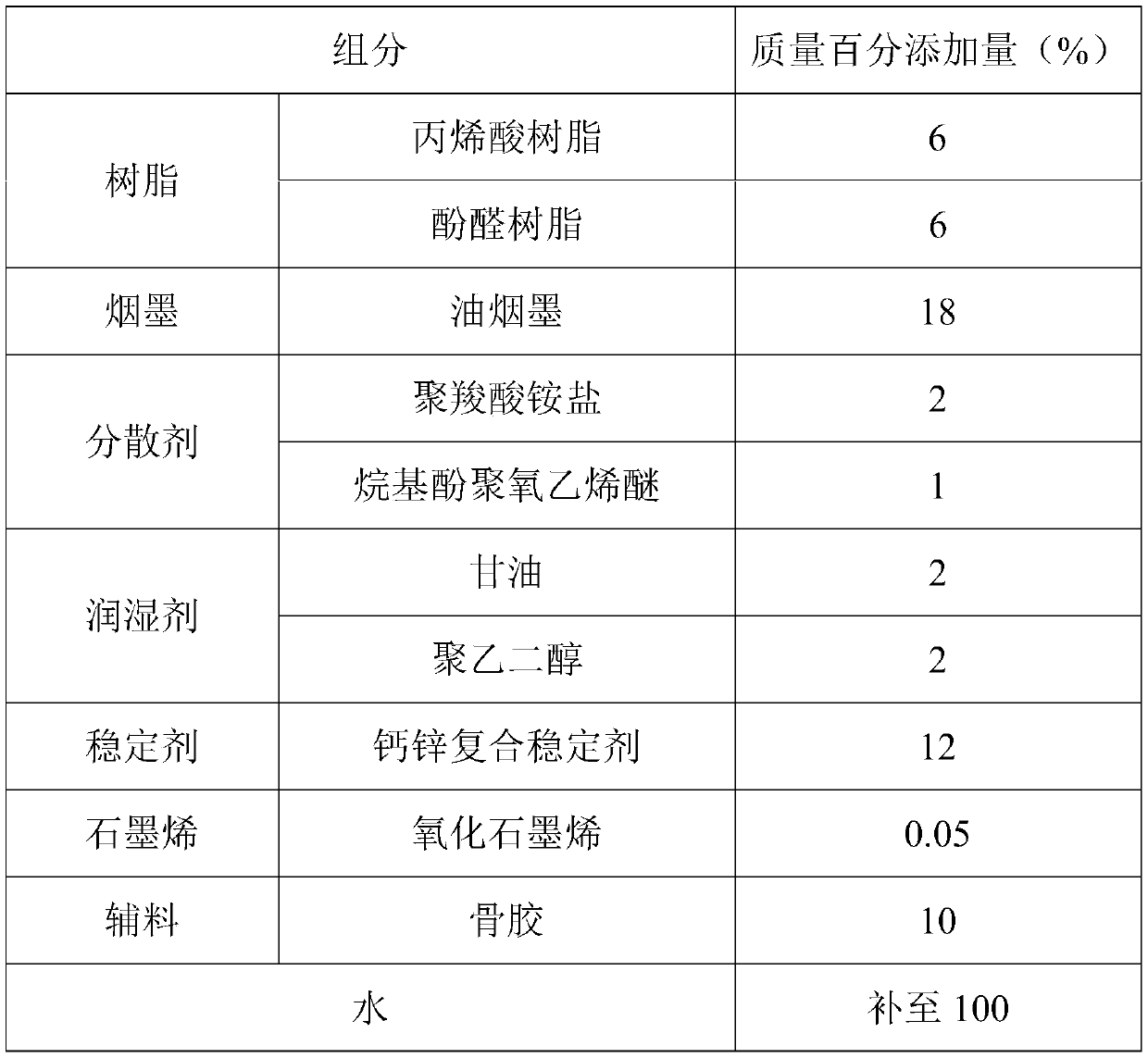

[0064] This embodiment provides a kind of graphene modified ink, the preparation raw material of described graphene modified ink comprises the following components by mass percentage:

[0065]

[0066] The preparation method of graphene modified ink described in the present embodiment comprises the following steps:

[0067] (1) The above-mentioned resin (acrylic resin and phenolic resin), lampblack ink, dispersant (polycarboxylate ammonium salt and alkylphenol polyoxyethylene ether), wetting agent (glycerin and polyethylene glycol), After graphene oxide, bone glue and water were mixed for 30 minutes, they were placed in a ball mill and ground for 60 minutes to obtain a mixed slurry;

[0068] (2) After mixing the mixed slurry obtained in step (1) with a stabilizer (calcium-zinc composite stabilizer) for 10 minutes, sieve it through a sieve with an aperture of 500 mesh to obtain the graphene-modified ink.

Embodiment 3

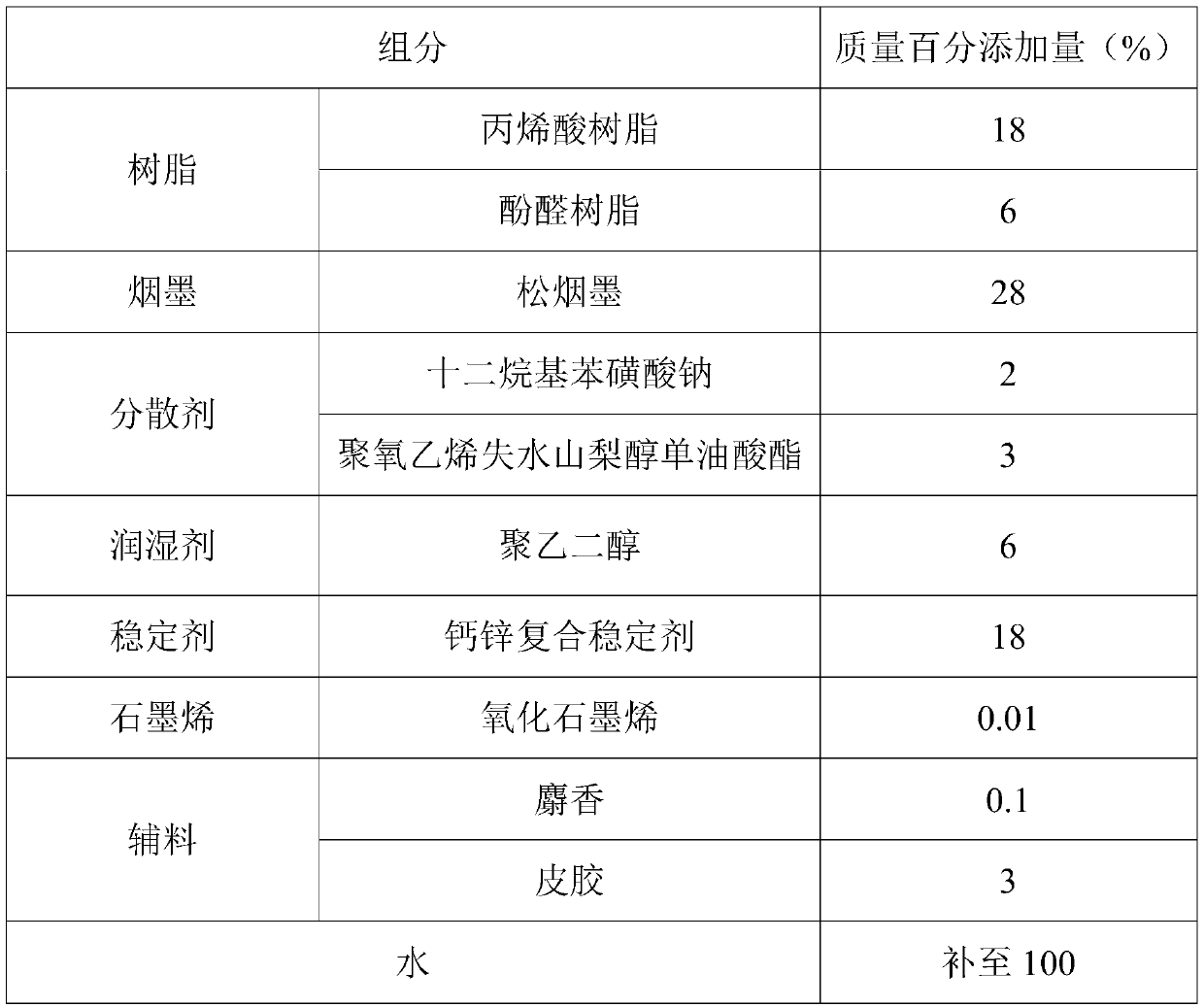

[0070] This embodiment provides a kind of graphene modified ink, the preparation raw material of described graphene modified ink comprises the following components by mass percentage:

[0071]

[0072] The preparation method of graphene modified ink described in the present embodiment comprises the following steps:

[0073] (1) The above-mentioned resin (acrylic resin and phenolic resin), pine smoke ink, dispersant (sodium dodecylbenzenesulfonate, polyoxyethylene sorbitan monooleate), wetting agent ( Glycerin and polyethylene glycol), graphene oxide, auxiliary materials (musk, hide glue) are mixed with water for 40 minutes, and placed in a ball mill to grind for 30 minutes to obtain a mixed slurry;

[0074] (2) After mixing the mixed slurry obtained in step (1) with a stabilizer (calcium-zinc composite stabilizer) for 20 minutes, sieve it through a 100-mesh sieve with an aperture to obtain the graphene-modified ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com