Offshore soil texture seabed jetting disturbance device

An offshore and earth-based technology, applied to spraying vehicles, sea area engineering, water conservancy projects, etc., can solve problems such as high strength of the seabed surface, limited pressure difference inside and outside the barrel foundation, difficult barrel foundation penetration, etc., to ensure construction quality and construction efficiency, short offshore operation time, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

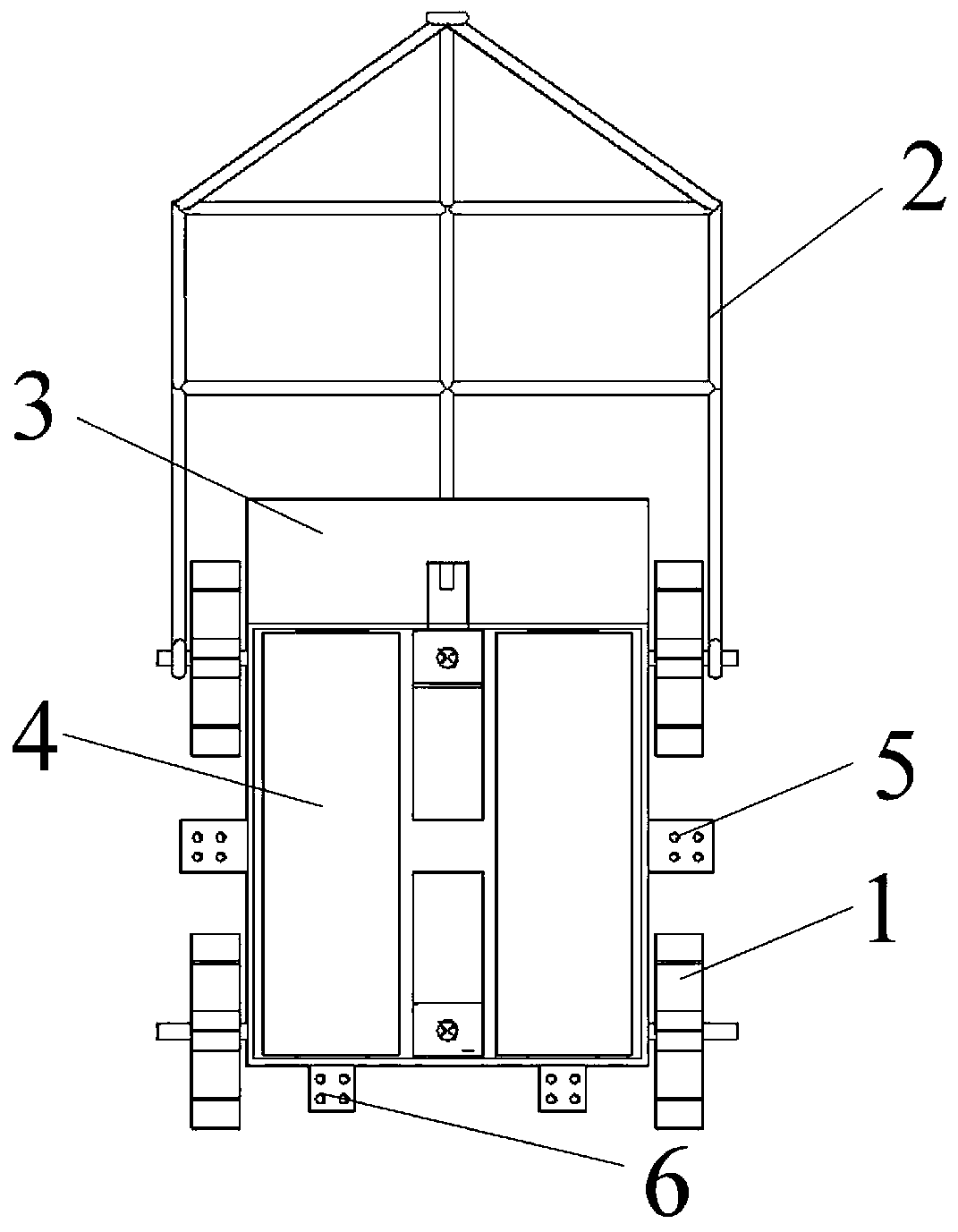

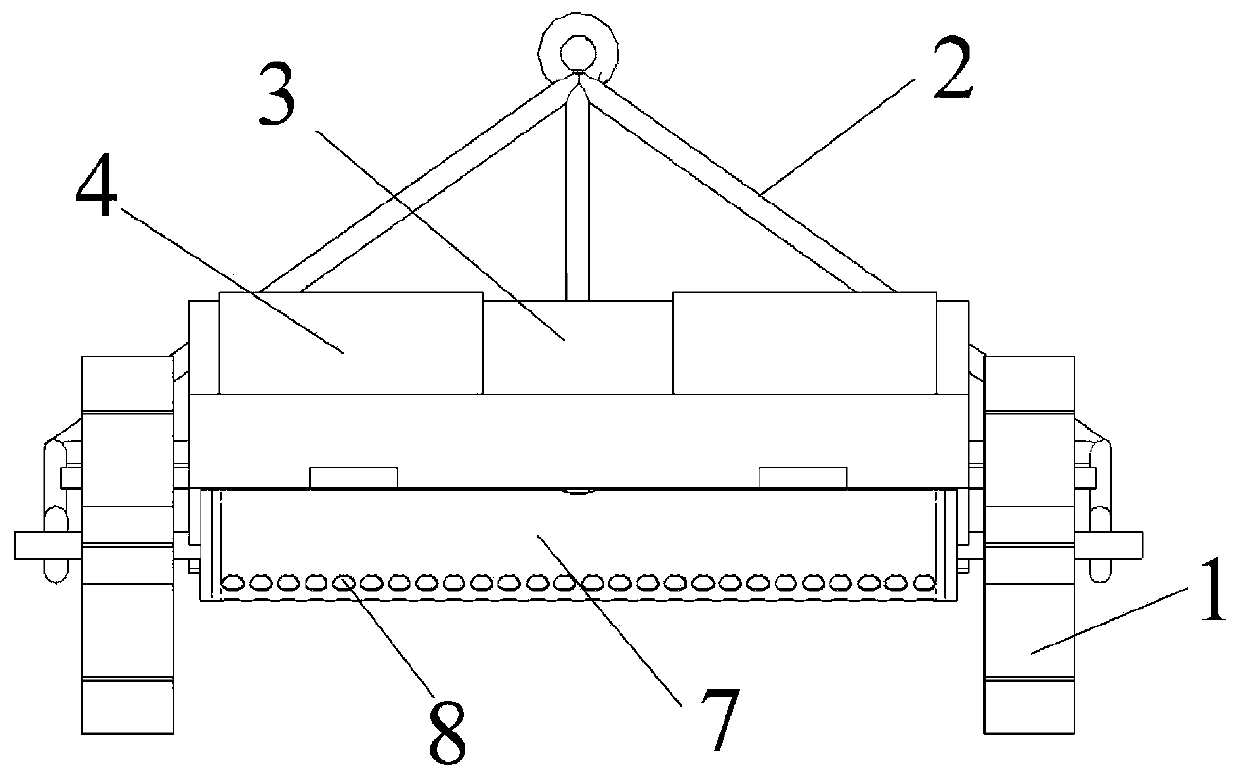

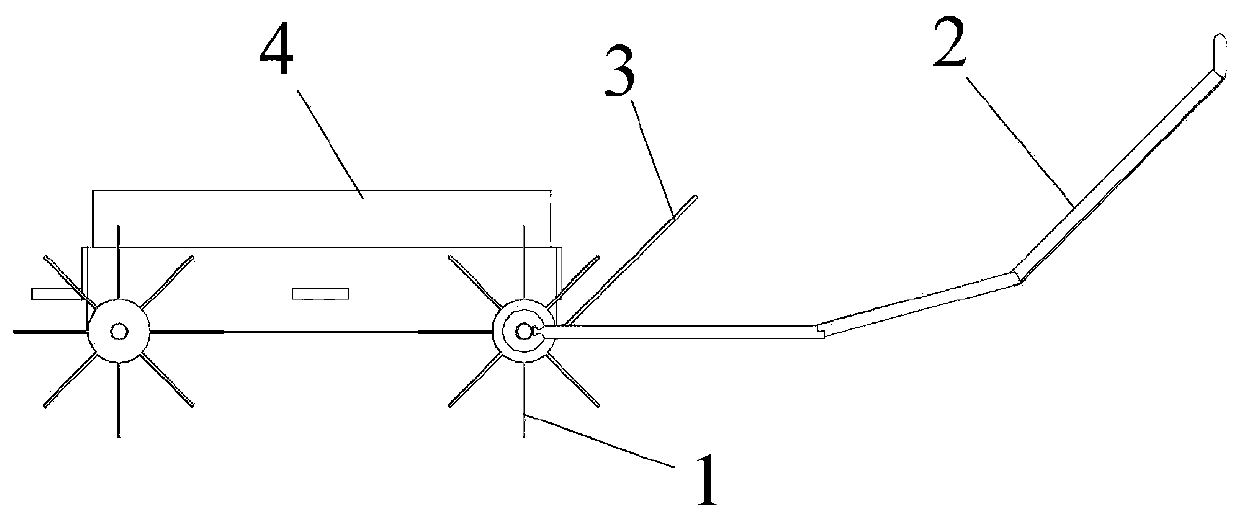

[0056] see figure 1 , a group of offshore soil seabed jet disturbance devices, including a shallow jet vehicle and a deep jet hammer, the shallow jet vehicle includes a trailer 9 and front and rear axle barrels 7 fixedly connected to the bottom of the trailer 9, respectively, The inside of the drag bucket 9 has a counterweight 4, and the insides of the front and rear axle barrels 7 are hollow, and the bottoms of the front and rear axle barrels 7 are respectively provided with multiple rows of spray holes 8 communicating with the inside, and the front and rear axle barrels 7 The upper part of the barrel is provided with the first water inlet 10 communicating with the inside and is connected with the first water injection pipe 12, and the two ends of the front and rear axle barrels 7 are respectively equipped with rotating shafts 11, and the traveling wheels 1 are installed on the rotating shafts 11. , the rotating shafts at the two ends of the front axle bucket are connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com