Manufacturing method of fixed-point furnace metal fixed-point bottle

A production method and a fixed point technology, applied in the direction of furnaces, furnace components, furnace types, etc., can solve problems such as short life, achieve the effects of prolonging life, reducing production costs, and quickly adjusting air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a method for making a fixed-point furnace gold fixed-point bottle, and the specific steps are as follows:

[0047] Step 1, prepare high-purity gold raw materials, the purity of high-purity gold needs to be above 6N, that is, the purity should be above 99.9999%. Often available through procurement of raw materials from external suppliers. Determine the weight of the high-purity gold to be 2.5kg according to the volume of the gold fixed-point bottle to be made, and adopt granular high-purity gold with a diameter of 5mm, and melt the high-purity gold raw material in batches in the quartz bottle.

[0048] Step 2, preparing a high-purity quartz bottle for holding high-purity gold, the bottom of the quartz bottle is closed and the top is open. The size of the quartz bottle is matched with the corresponding fixed point holding furnace hearth. The preferred size of the quartz bottle is 620mm, or the standard empty quartz bottle provided by the manufac...

Embodiment 2

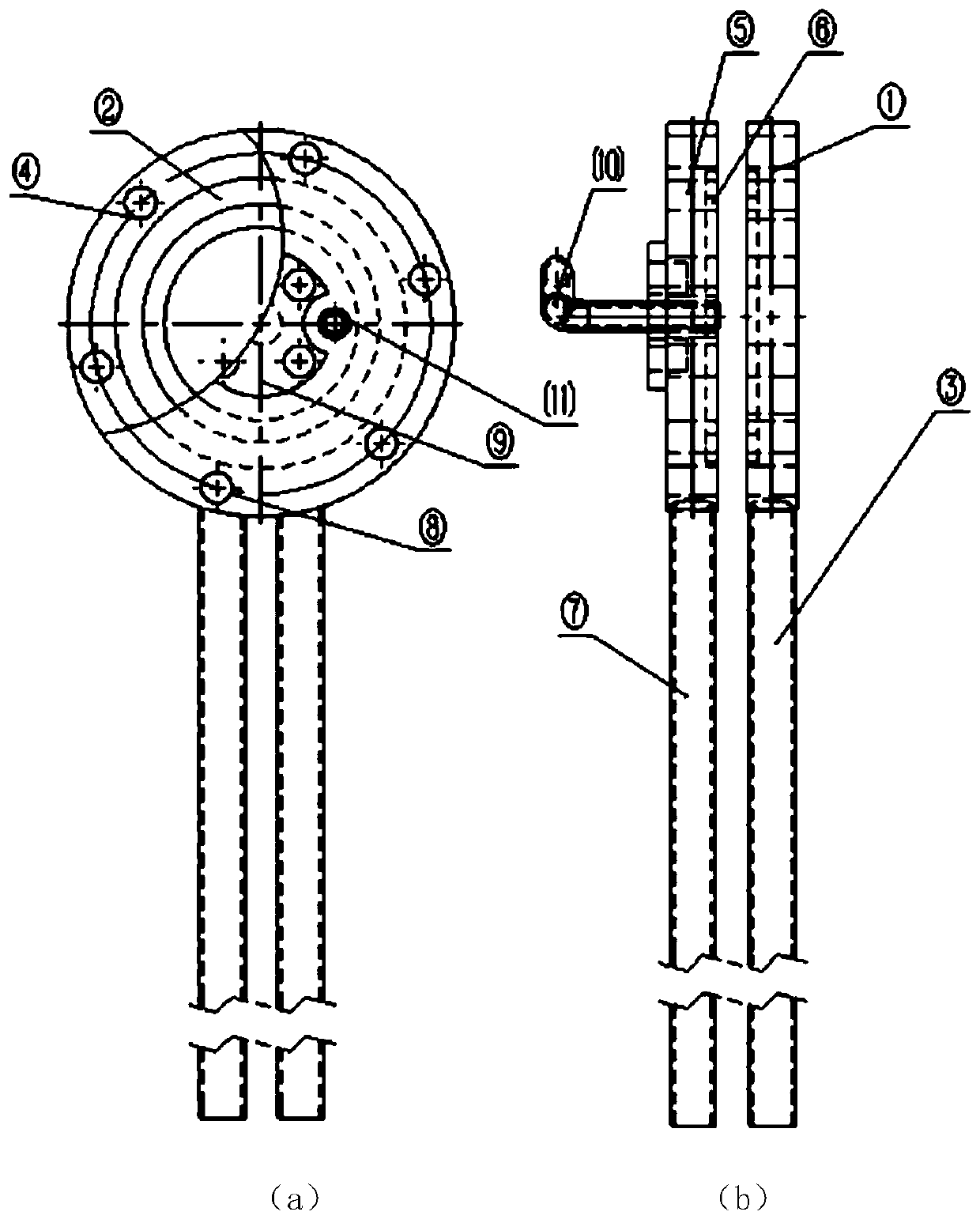

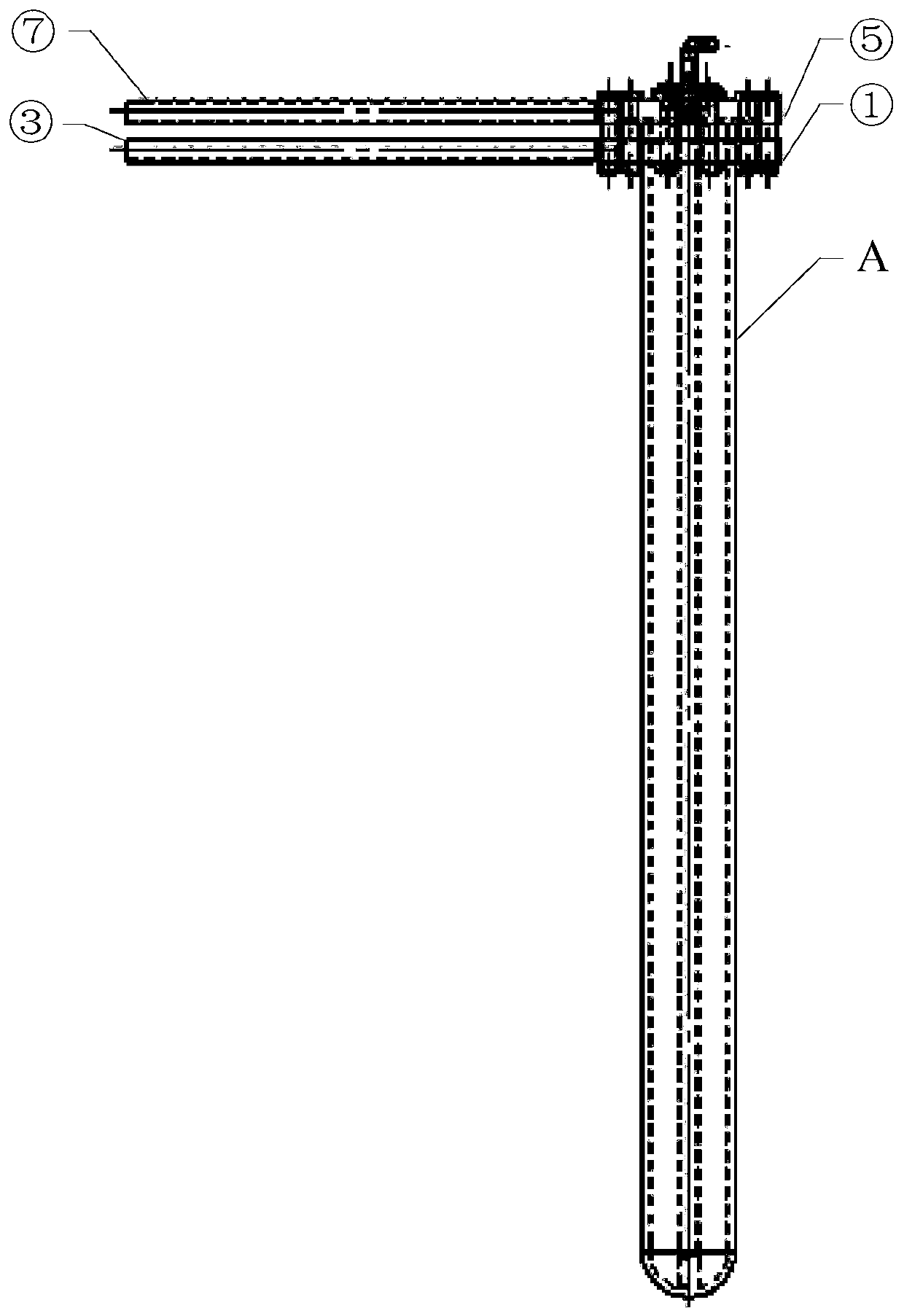

[0061] This embodiment provides a sealing protection kit, which includes a lower assembly body 1 and an upper assembly body 5 that are detachably and sealingly adapted to each other. A sealing sleeve is provided at the upper port of the fixed point vial. The main body 1 of the lower assembly is provided with 4 to 8 bolt holes 4 of the lower assembly, and all the bolt holes 4 of the lower assembly are evenly distributed along the circumferential direction of the main body 1 of the lower assembly; the main body of the upper assembly 5 is provided with 4 to 8 bolt holes of the upper assembly 8. All the bolt holes 8 of the upper assembly are evenly distributed along the circumferential direction of the upper assembly main body 5; through the bolts sequentially penetrate the upper assembly bolt holes 8 and the corresponding lower assembly bolt holes 4 to realize the detachable connection between the upper assembly main body 5 and the lower assembly main body 1 . The lower componen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com