Optical fiber differential pressure sensing system with high static pressure and low differential pressure

A technology of differential pressure sensing and optical fiber sensor, which is applied to the measurement of pressure difference between multiple valves, the detection of fluid flow by measuring the pressure difference, and the use of optical devices to eliminate temperature drift, improve sensitivity, and improve measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

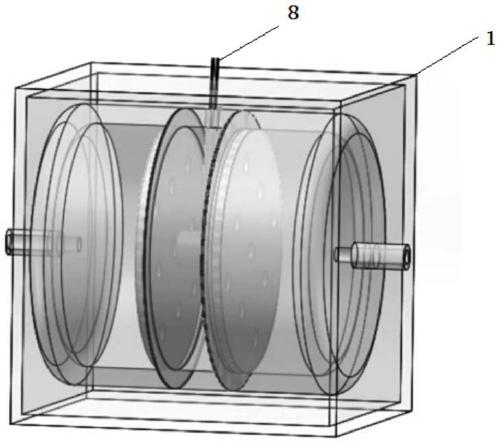

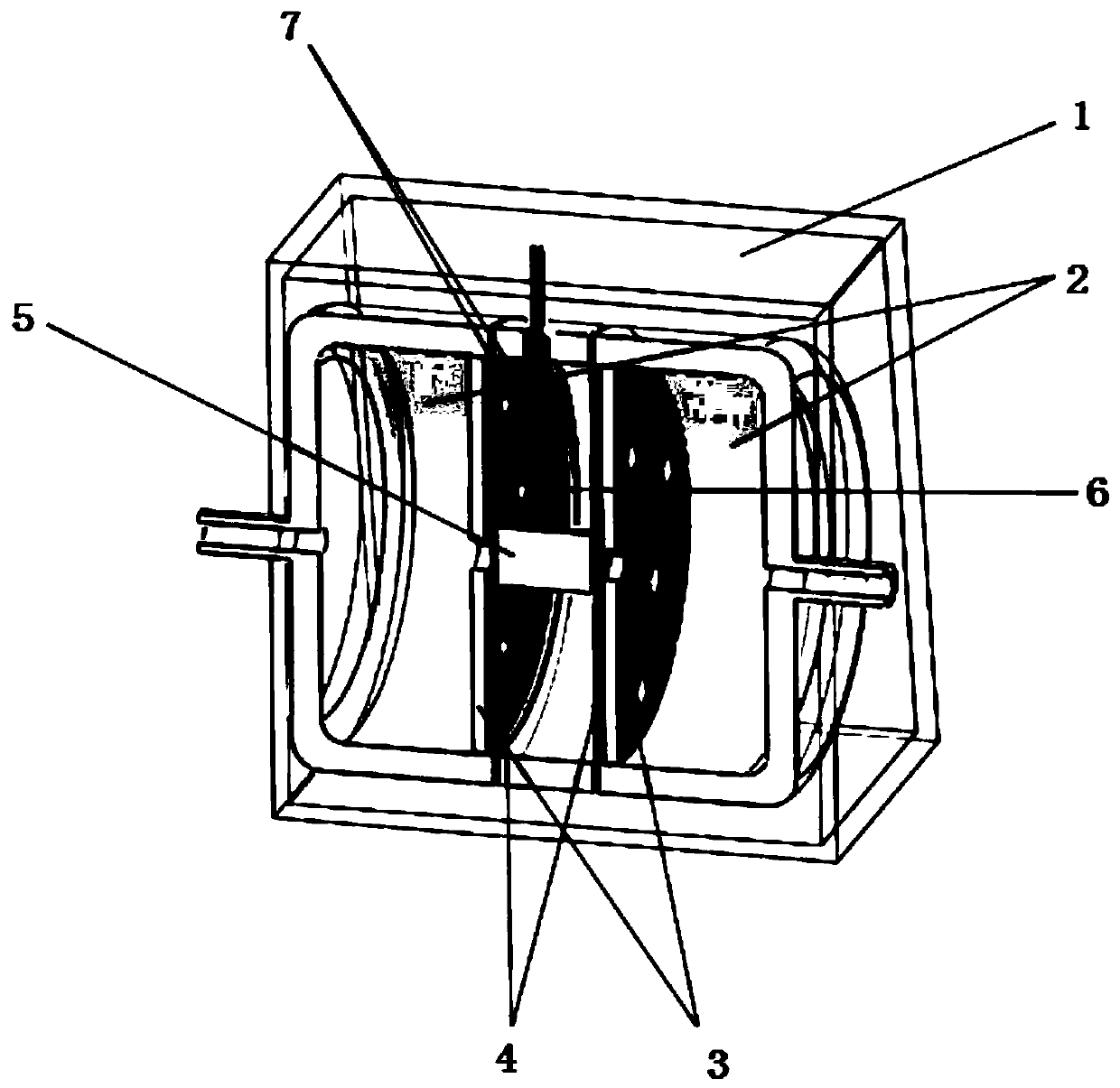

[0038] Such as Figure 1-Figure 2 As shown, a highly sensitive high static pressure and low differential pressure optical fiber differential pressure sensor of the present invention seals and divides the pressure pipe 2 into three chambers through two pressure sensitive diaphragms 4, and the third chamber in the middle adopts a connection The rod 5 is connected with two pressure-sensitive diaphragms 4, so that the pressure difference between the two chambers at both ends is converted into the displacement change of the connecting rod 5. By connecting a cantilever arm 6 to the connecting rod 5, when the displacement of the connecting rod 5 occurs The change causes the cantilever arm 6 to deform, and two optical fiber sensors 7 are used to measure the positive and negative deformation of the cantilever arm 6 to eliminate temperature drift, amplify the differential pressure drift to twice the original value, and improve the measurement accuracy of the sensor. The scheme adopted i...

Embodiment 2

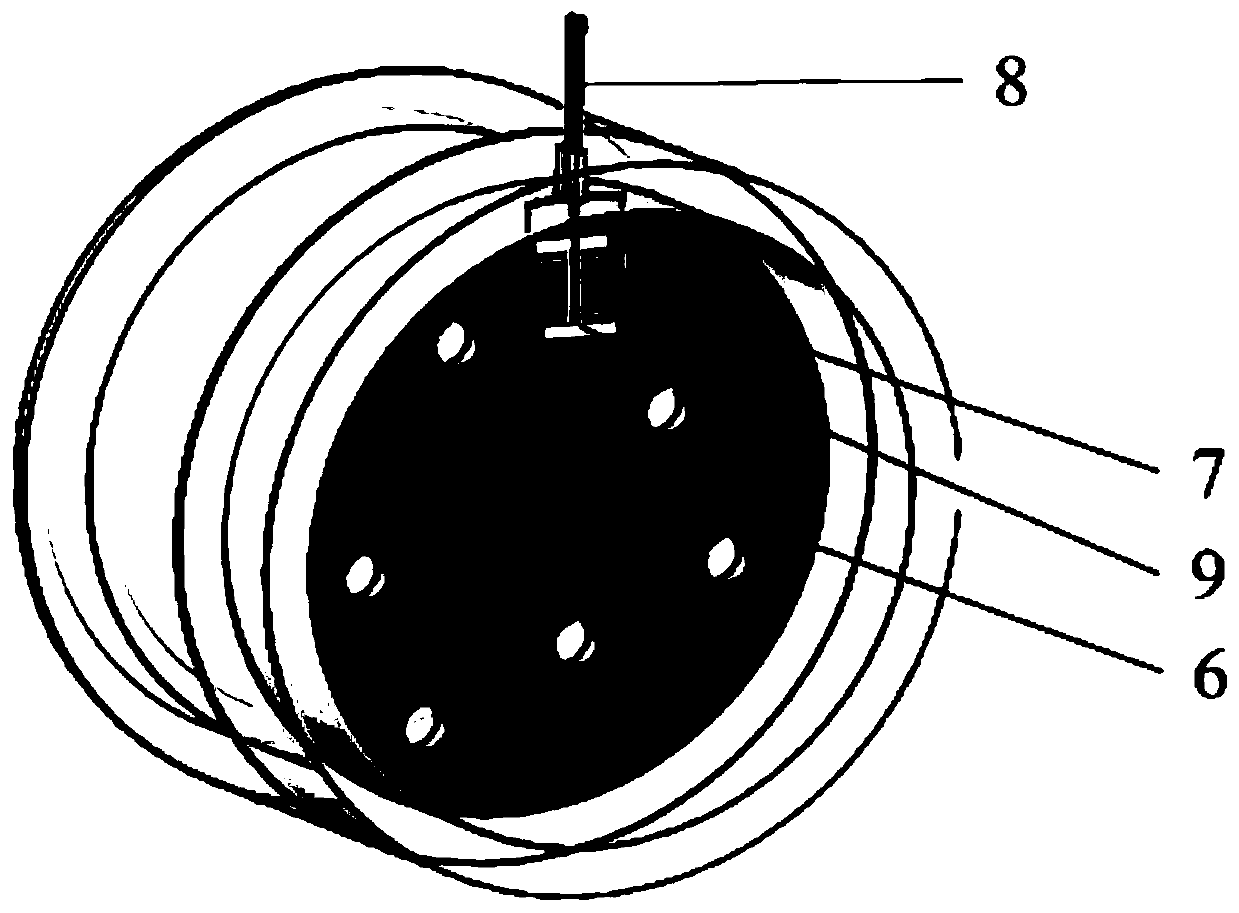

[0042] Such as Figure 4-Figure 5As shown, a high static pressure and low differential pressure optical fiber differential pressure sensing system of the present invention senses pressure through a pressure sensitive diaphragm 3, which reduces the process of intermediate transmission, and uses two optical fiber sensors 7 to pair the pressure sensitive diaphragm The deformation of 3 is measured positively and negatively, eliminating temperature drift, amplifying the differential pressure drift to twice the original value, and improving the measurement accuracy of the sensor. The scheme adopted is as follows:

[0043] An optical fiber differential pressure sensing system with high static pressure and low differential pressure, comprising a packaging case 1, and an optical fiber differential pressure sensing system located in the packaging case 1, the optical fiber differential pressure sensing system includes two optical fiber sensors 7. Pressure-sensitive diaphragm 4, two displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com