Automatic wharf production operation support system

An automated terminal and support system technology, applied in the field of automated terminal production operation support systems, can solve problems such as easy-to-miss tasks, heavy and complex, limited working environment for terminal staff, avoid omissions or delays, improve gate entry efficiency, The effect of simplifying the entry process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

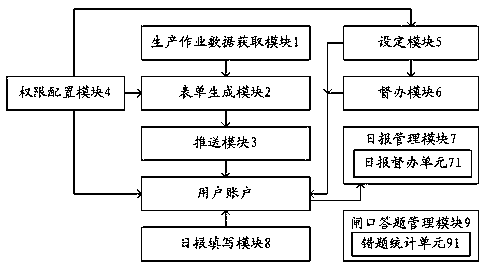

[0022] The automatic terminal production operation support system proposed by the present invention, such as figure 1 As shown, it includes a production operation data acquisition module 1, a form generation module 2 and a push module 3; wherein, the production operation data acquisition module 1 is used for acquiring production operation data from each production operation module; the form generation module 2 is used for The production job data acquired by the job module generates a job form; the push module 3 is used to send the job form to the set user mailbox according to the set time.

[0023] Each production operation module is related to the terminal production operation, such as ship dynamics, ship status in port, summary of day and night production plans, day shift production plan, AGV, infrastructure, berth, carrier, route,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com