Unsteady plasma excitation layout design method for inhibiting compressor stall

A plasma and unsteady technology, applied in the field of plasma, can solve the problem of insufficient stalling capacity of the compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings.

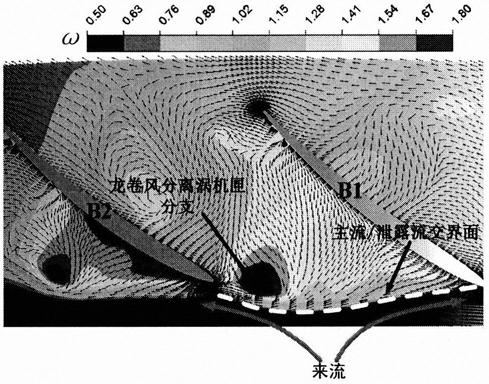

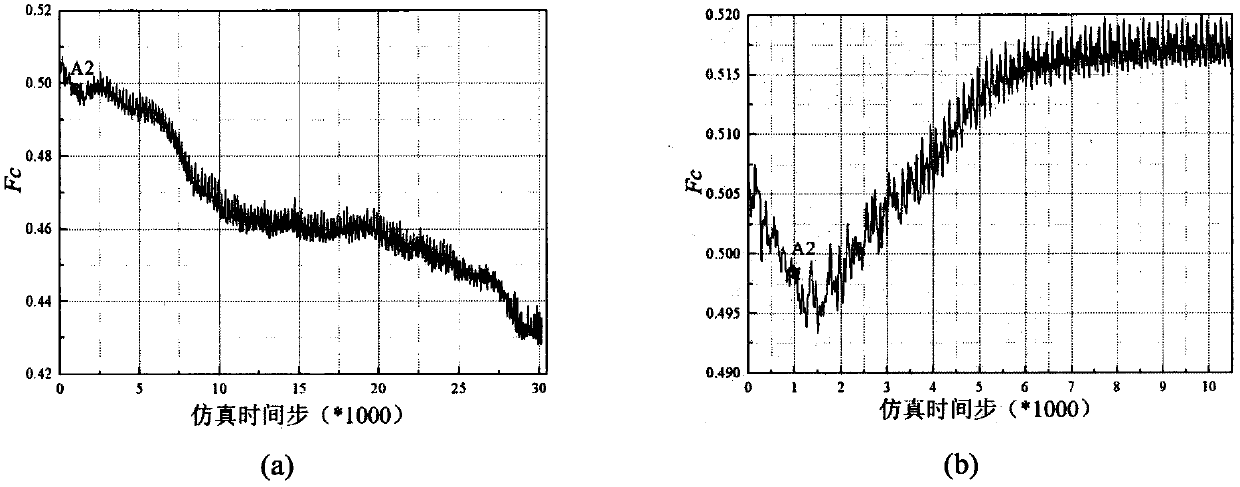

[0048] 1. The determination method of the change law of the unsteady plasma excitation body force direction

[0049] At present, the research on the plasma flow control of compressor stall is mainly based on the sine wave DBD plasma excitation, and the plasma excitation used in the present invention refers to the sine wave DBD plasma excitation.

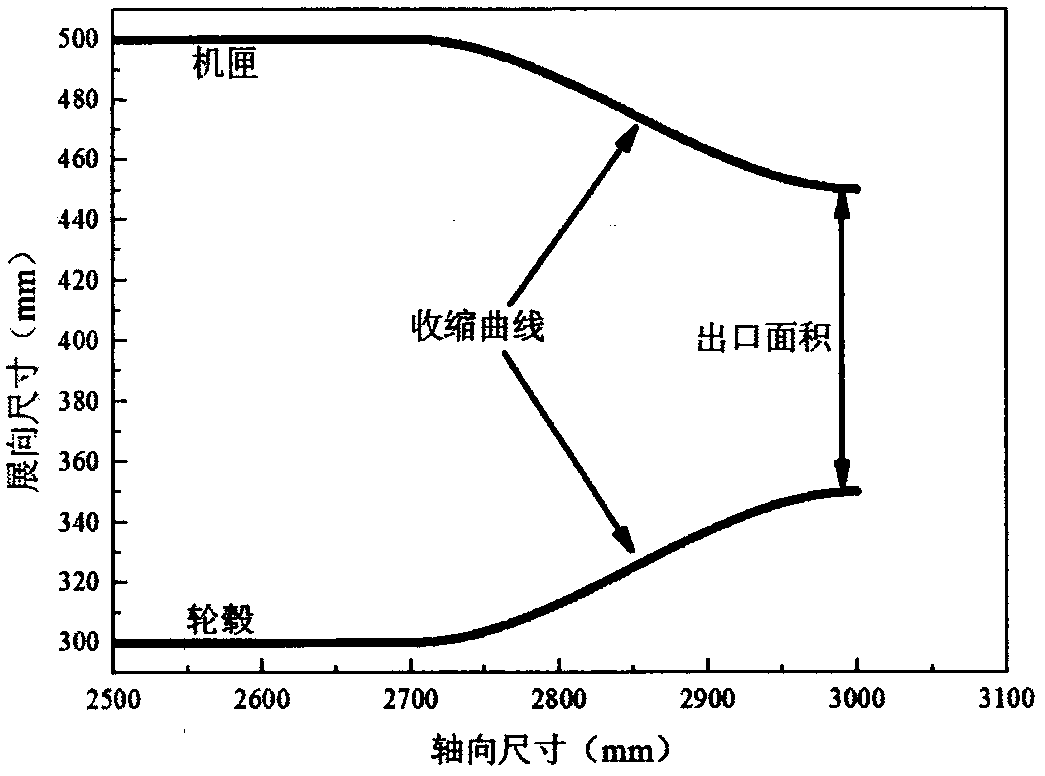

[0050] The invention uses numerical simulation and experiment, and the adopted experimental device includes a plasma power supply and a plasma excitation casing. The numerical simulation method provides the flow characteristics of the rotor tip near the stall point. Based on the flow characteristics of the rotor tip near the stall point, the unsteady plasma excitation layout is designed, and the plasma excitation casing is formed by processing. The plasma excitation casing is provided with a plasma power supply. High pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com