Dust suppression system applied to material pile greenhouse

A greenhouse and stockpile technology, applied in the direction of using liquid separation agent, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of unorganized dust emission, non-concentrated emission, large diffusion range, death, etc., to save treatment costs, Effect of reducing dust spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

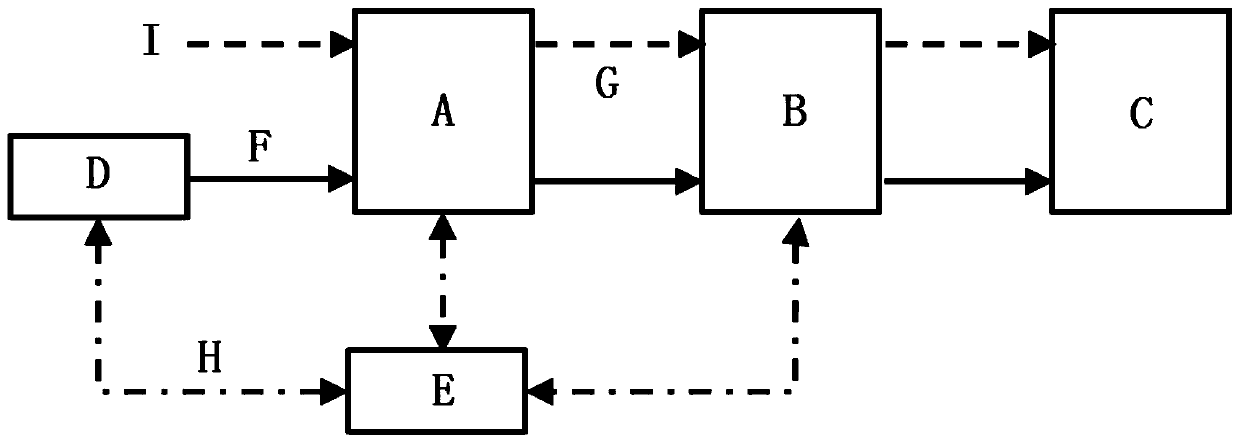

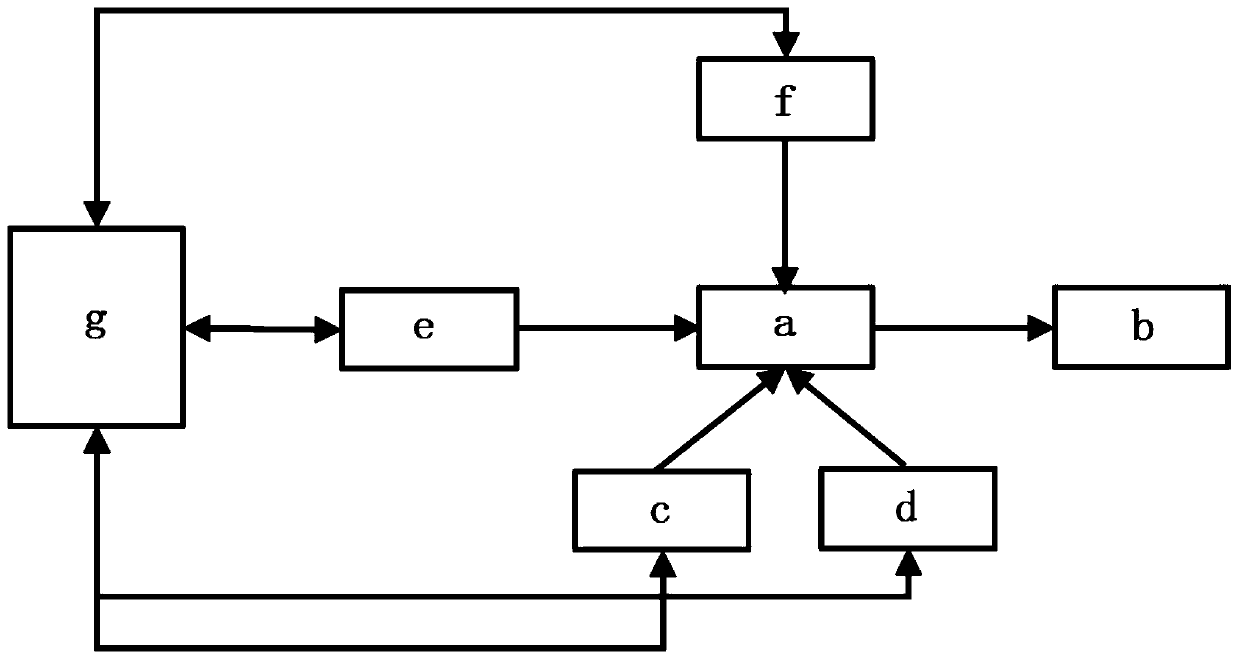

[0102] The dust suppression system of the present invention is installed in the stockpile greenhouse to suppress the unorganized dust.

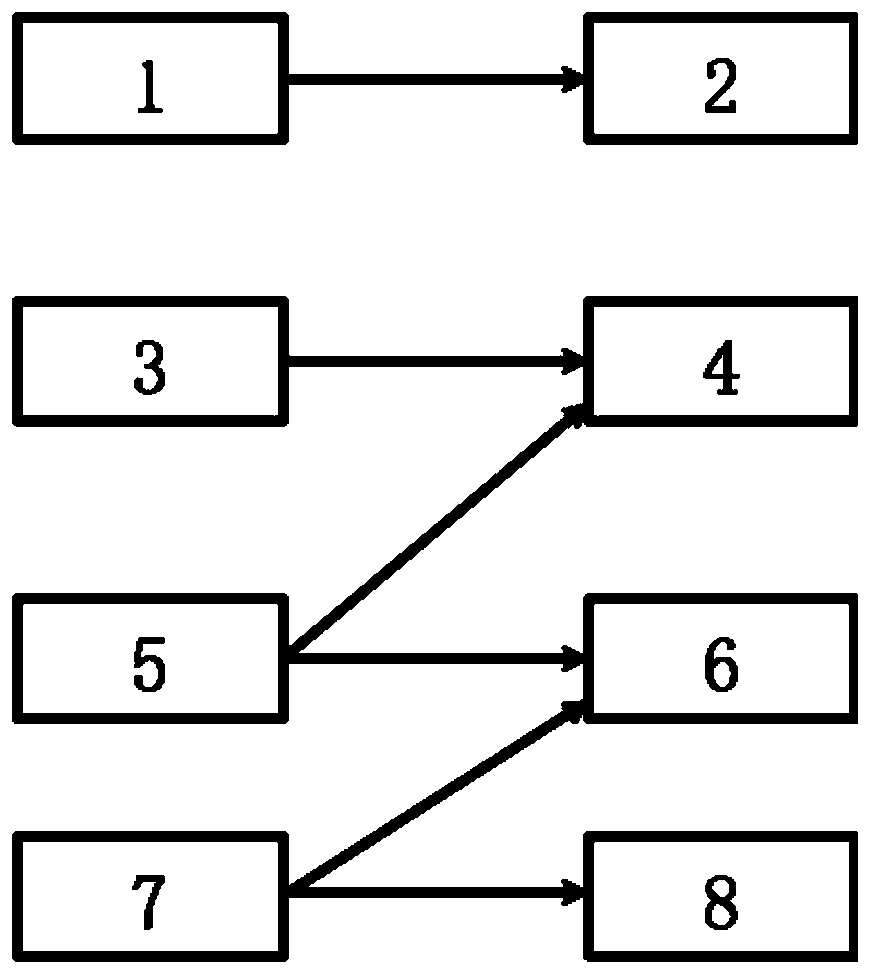

[0103] 1) The vehicle visual recognition module 1 and the high-pressure car washing module 2 are installed outside the entrance and exit of the material shed. The vehicle visual recognition module 1 is used to monitor, identify and record the vehicles entering and exiting the material shed, which can identify the vehicle license plate number and whether the truck box is covered , Add felt cloth to cover, judge and record whether the truck enters the car washing machine, etc., and prompt the vehicles leaving the greenhouse to enter the high-pressure car washing module 2 for cleaning. Then, the high-pressure car washing module 2 is used to automatically wash the vehicles out of the shed to prevent the dust carried by the vehicles from being scattered on the road and causing secondary dust pollution from the source.

[0104] 2) The dust concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com