Pipeline all-position automatic tungsten inert gas welding (TIG welding) machine and welding process thereof

An all-position, pipeline technology, used in welding equipment, welding accessories, manufacturing tools, etc., can solve the problems of low degree of automation, inability to balance welding quality and efficiency, and achieve low labor intensity, easy welding quality assurance, and stable wire feeding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to better illustrate the technical scheme of the present invention, the present invention will be further described below in conjunction with the accompanying drawings:

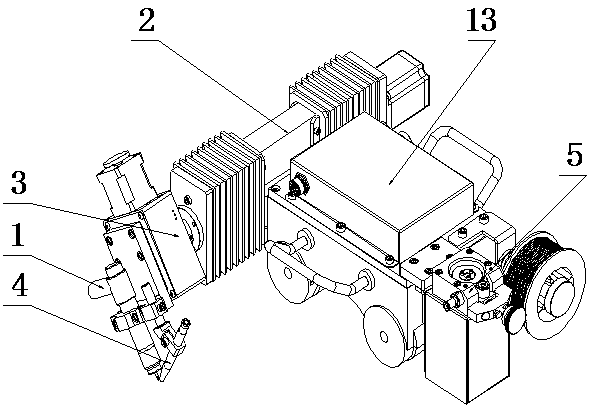

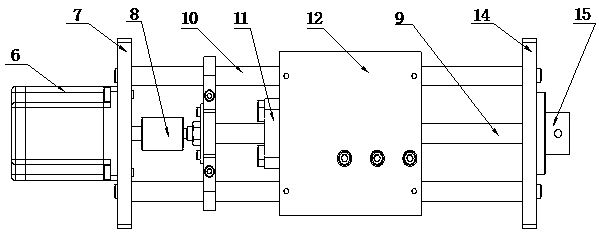

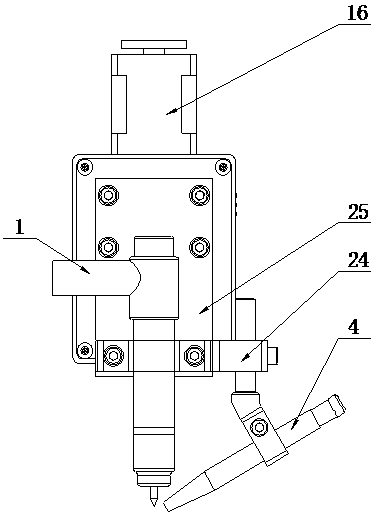

[0051] see figure 1 , an all-position automatic TIG welding machine for pipelines, including a welding trolley, which moves in a circle along the pipeline, a wire feeding mechanism 5 and a welding torch 1 are arranged on the body of the welding trolley, and a hot wire nozzle 4 is arranged at the end of the wire feeding mechanism 5 , the hot wire nozzle 4 is a copper tube, and one end of the hot wire nozzle 4 is connected to the heating power supply through a wire, and also includes a positive connecting wire, one end of the positive connecting wire is connected to the heating power supply, and the other end is a free end. When in use, the free end is contacted with the pipeline to be welded to form a loop, and the welding wire is heated when it passes through the hot wire nozzle 4 to ensure th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com