Double-drive bicycle with variable front-drive structure

A bicycle and front-drive technology, which is applied to vehicle components, vehicle gearboxes, and rider drives, can solve the problems of inconvenient front and rear drive switching, small driving force, and complex structure, and achieve improved drive capability, practicability, and simple structure , the effect of smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

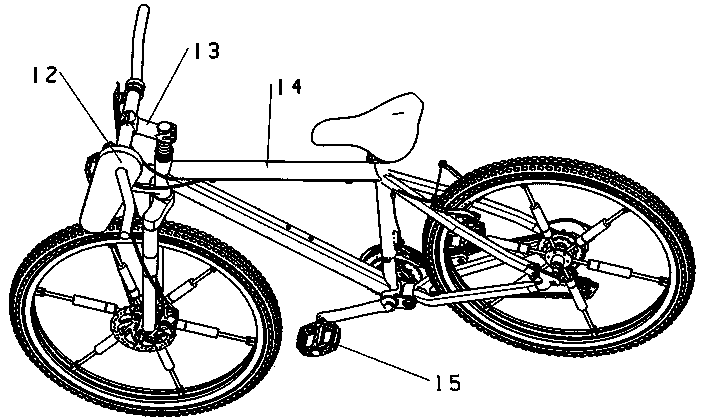

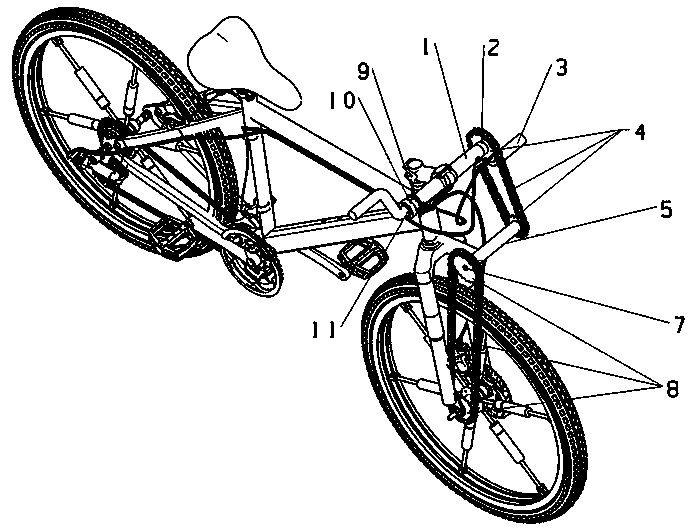

[0032] See attached Figure 1-7 , a dual-drive bicycle with a variable front-drive structure, mainly comprising a vehicle frame 14, front and rear wheels, a vehicle seat, and a pedal 15; , the pedal 15 is installed under the vehicle seat, the pedal 15 can drive the sprocket, and the flywheel of the rear wheel is driven by the chain; it is characterized in that: the top of the front end of the vehicle frame 14 is connected with a cylinder 1 through a cross bar 13, and the cross bar 13 and the cylinder 1 Tighten in the form of buckles; relative movement and rotation are not allowed; the front end of the frame 14 is provided with a T-shaped cylinder 5, and the frame 14 and the T-shaped cylinder 5 are tightened in the form of buckles, so that relative movement and rotation cannot occur ; There is a primary transmission device 4 between the left side of the cylinder 1 and the T-shaped cylinder 5; a secondary transmission device 8 is provided between the right side of the T-shaped c...

Embodiment 2

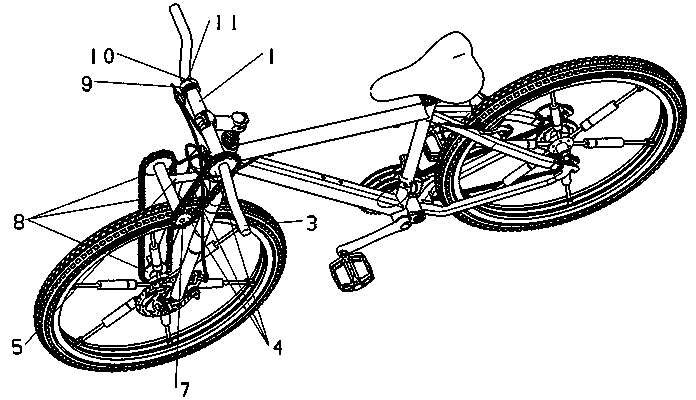

[0036] Different from Embodiment 1, a locking mechanism is provided between the right crank 3 and the cylinder 1; the locking mechanism includes a locking cylinder 9, a slider 10 and a spline 11, wherein the locking cylinder 9 and The cylinder 1 is fixedly connected by screws; the inside of the locking cylinder 9 is provided with a chute, the spline 11 is fixedly connected with the right crank 3 by welding, the right side of the slider 10 is provided with a spline groove to cooperate with the spline 11, and the slider The left side of 10 is provided with boss and chute to cooperate, and the cooperation between the boss on slide block 10 left side and locking cylinder 9 chutes has damping existence, can not slide by oneself.

[0037] When using the rear drive mode, the slider 10 moves to the spline 11, the spline groove on the right side of the slider 10 cooperates with the spline 11, and the boss on the left side of the slider 10 cooperates with the chute of the locking cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com