Oxidant preparation assembly and sewage treatment equipment using same

A technology of oxidant and components, which is applied in the direction of oxidized water/sewage treatment, water/sewage treatment equipment, water/sewage treatment, etc., can solve the problems that cannot meet the high efficiency and high energy treatment of wastewater, and the cumbersome process of wastewater treatment, etc., and achieve good results , Strong oxidation performance and fast reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 01

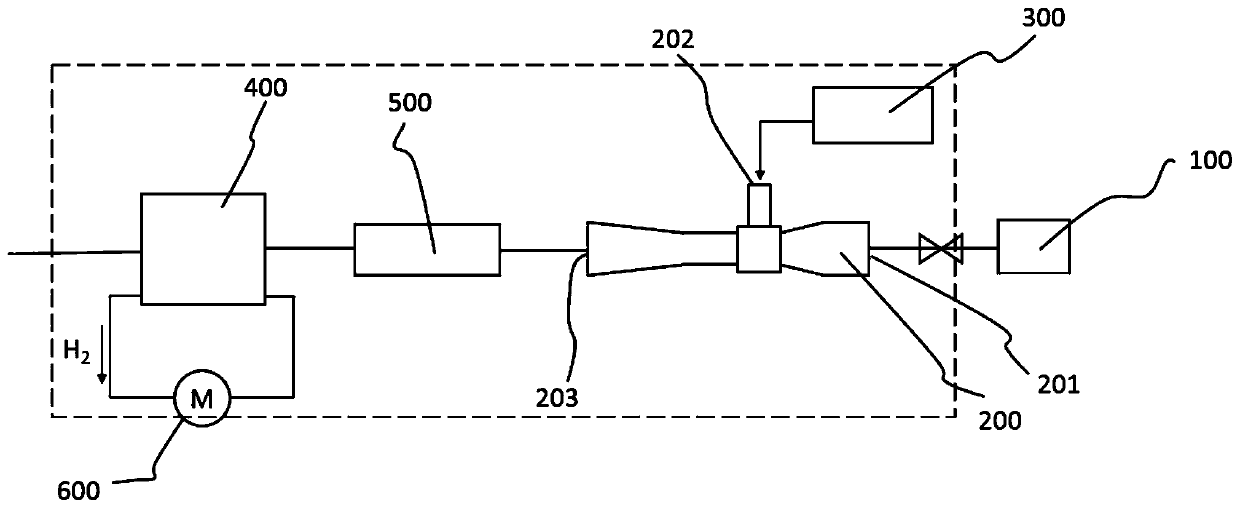

[0048] Such as figure 1 As shown, the oxidant preparation assembly includes a mixing unit 200, an oxygen supply unit 300, an electrolysis unit 400 and a super nanobubble generating unit 500, the mixing unit 200 is provided with a liquid inlet 201 and a liquid outlet 203, and the oxygen supply unit 300 is used to use The waste water passed into the mixing unit 200 is filled with oxygen-containing bubbles.

[0049] The electrolysis unit 400 is used to convert oxygen-containing bubbles into oxidizing substances with strong oxidizing properties.

[0050] Wherein, the super nanobubble generating unit 500 is connected to the liquid outlet 203 of the mixing unit 200, and the mixing unit 200, the super nanobubble generating unit 500 and the electrolysis unit 400 are connected in sequence.

[0051] The working principle of this embodiment is:

[0052] Wastewater enters the mixing unit 200 through the liquid inlet 201, and the oxygen supply unit 300 supplies oxygen-containing gas / wate...

Embodiment 02

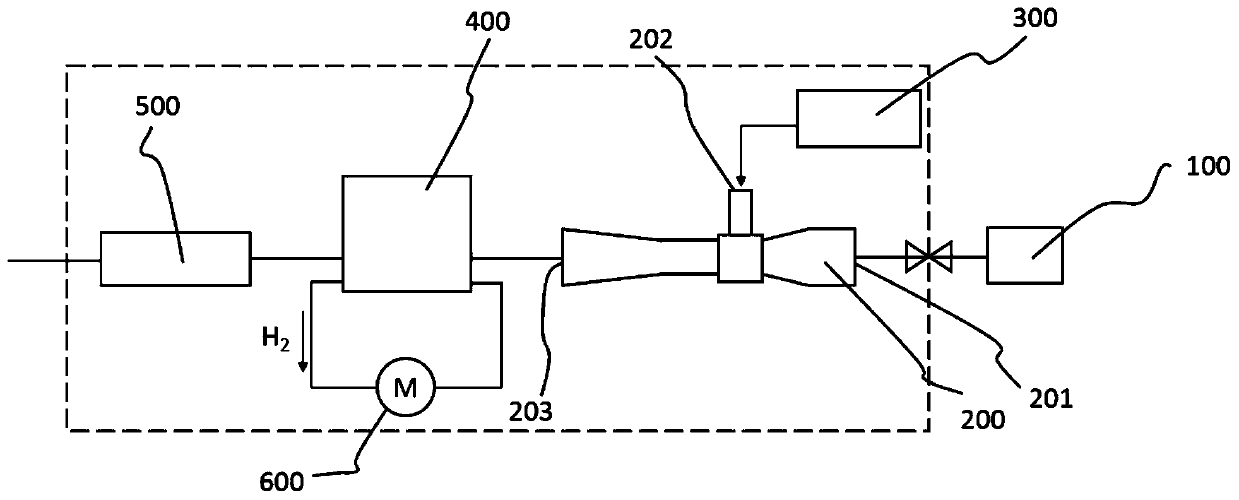

[0057] Such as figure 2 As shown, the oxidant preparation assembly includes a mixing unit 200, an oxygen supply unit 300, an electrolysis unit 400 and a super nanobubble generating unit 500, the mixing unit 200 is provided with a liquid inlet 201 and a liquid outlet 203, and the oxygen supply unit 300 is used to use The waste water passed into the mixing unit 200 is filled with oxygen-containing bubbles.

[0058] The electrolysis unit 400 is used to convert oxygen-containing bubbles into oxidizing substances with strong oxidizing properties.

[0059] Wherein, the electrolysis unit 400 is connected to the liquid outlet 203 of the mixing unit 200, and the mixing unit 200, the electrolysis unit 400 and the super nanobubble generating unit 500 are connected in sequence.

[0060] The working principle of this embodiment is:

[0061] Wastewater enters the mixing unit 200 through the liquid inlet 201, and the oxygen supply unit 300 supplies oxygen-containing gas / water containing o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com