Method for preparing feconicu high-entropy alloy and tic particles composite reinforced copper matrix composite material by vacuum arc melting

A technology of vacuum arc smelting and copper-based composite materials, applied in the field of arc smelting reaction synthesis, can solve the problems of high cost, ball-milling medium material pollution, complicated process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

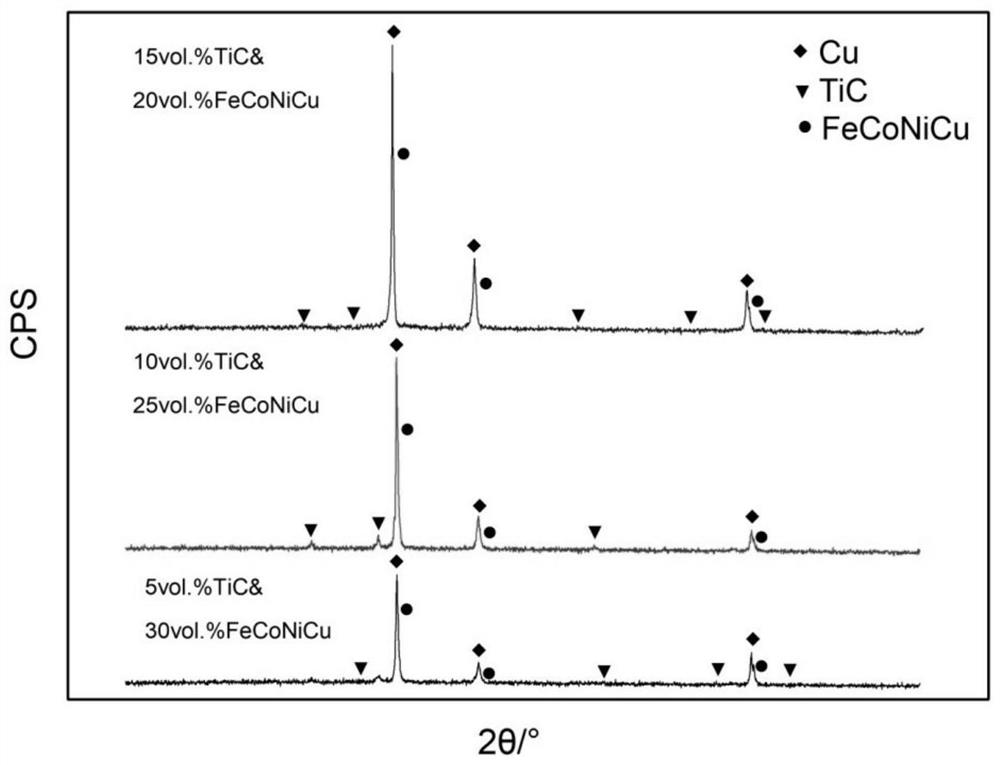

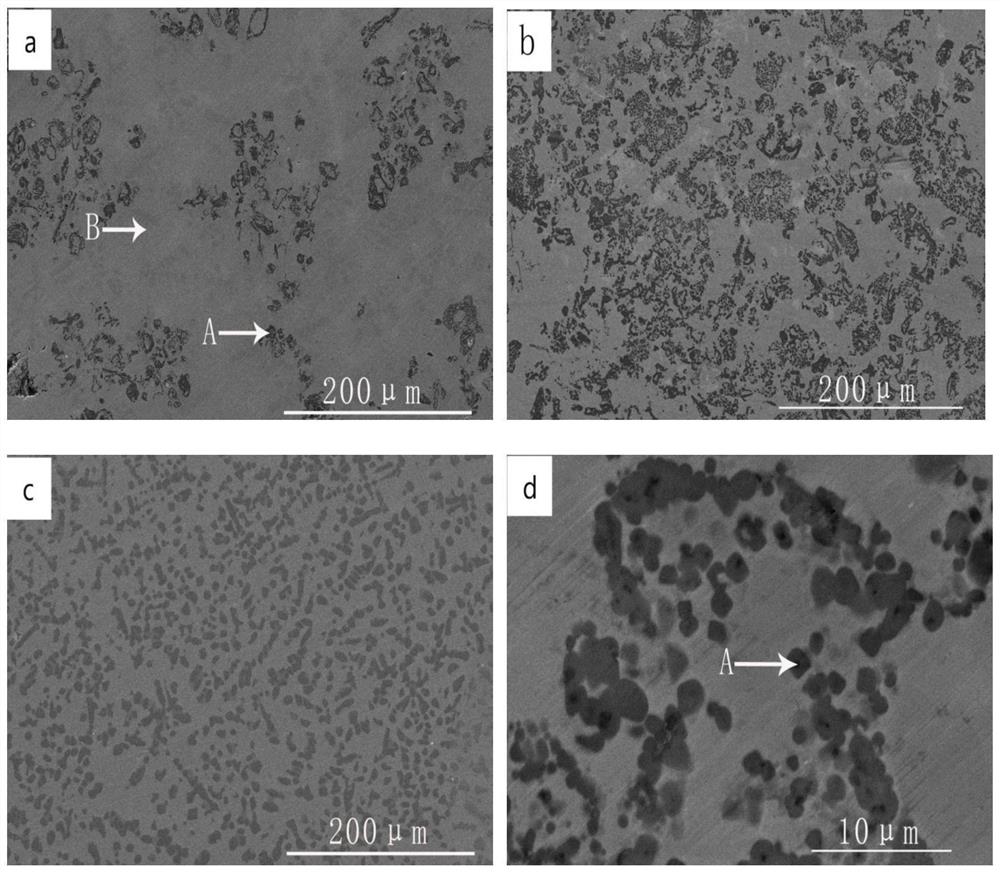

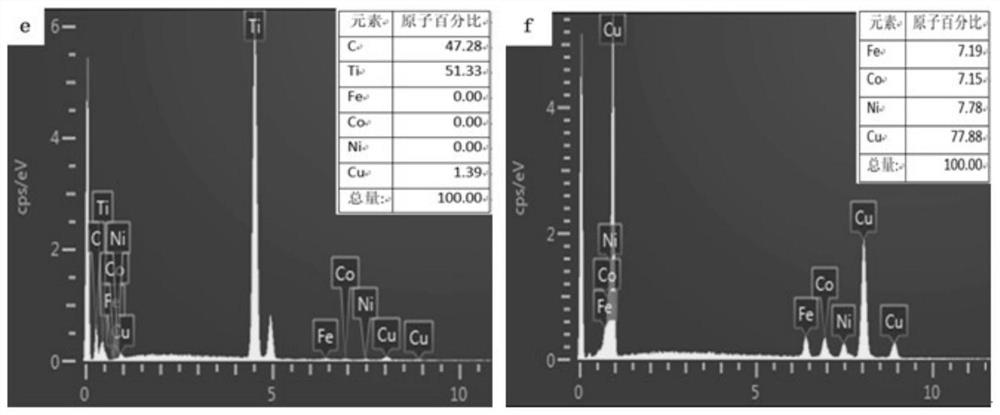

[0026] Example: Ti-C-FeCoNiCu-Cu system

[0027] (1) Prepare the reaction sample. Use Ti, C, Fe, Co, Ni, Cu elemental powder according to the reinforcement volume fraction (15vol.%TiC&20vol.% FeCoNiCu), to get a 20g reaction sample, you need 0.986g of Fe powder and 0.986g of Co powder 1.041g, Ni powder 1.036g, Cu powder 1.122g, Ti powder 1.423g, C powder 0.360g, Cu block 14.022g, then put the powder into the ball ink tank, ball milling with ball powder ratio 5:1, 250rpm speed ball milling, Then extrude into a billet with a pressure of 150MPa to make a compact sample;

[0028] (2) Vacuumizing the samples Put the compact sample and 14.022g copper block into the vacuum arc melting furnace, and vacuumize to 10 -4 ~10 -3 Pa;

[0029] (3) Reaction synthesis Adjust the current to control the size of the arc. The maximum current does not exceed 250mA. The melting process of the sample is clearly observed through the monitoring hole. After it is completely melted and mixed evenly, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com