Flue gas afterburning type waste heat steam injection boiler, method and system for producing high-pressure superheated steam

A technology of superheated steam and flue gas, which is applied in the field of supplementary-fired steam injection boilers, which can solve problems such as difficulty in producing steam with higher pressure levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

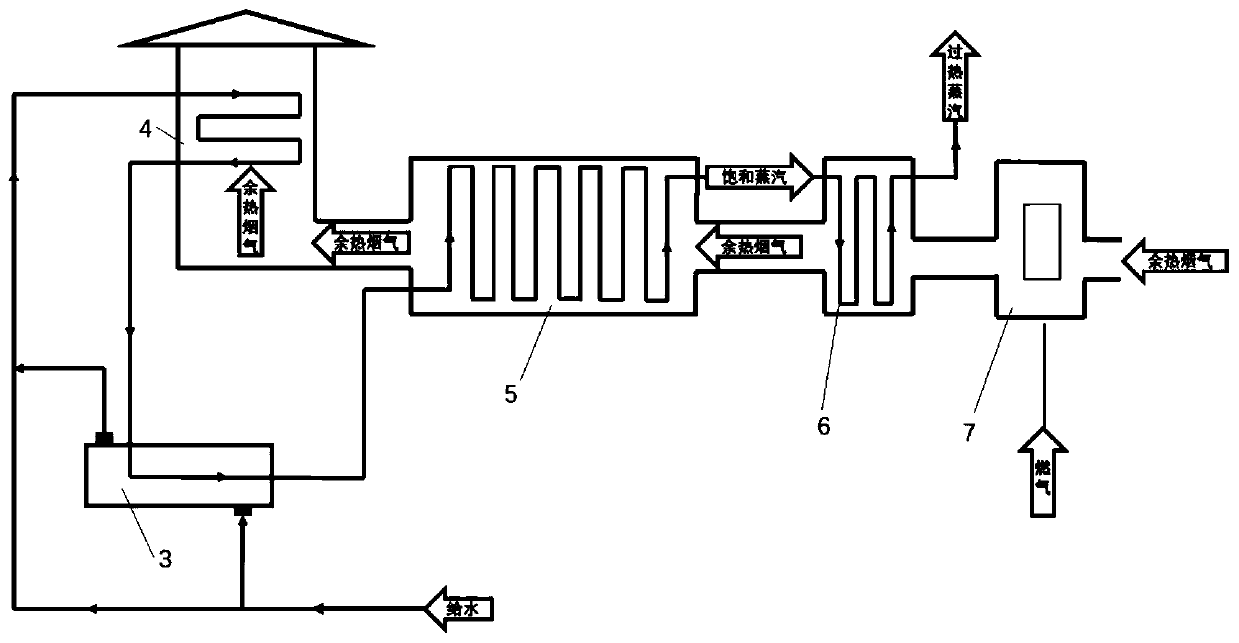

[0072] refer to figure 1 , this embodiment provides a flue gas supplementary combustion type waste heat steam injection boiler for producing high-pressure superheated steam, including: an economizer 4, a feed water preheater 3 (optional), a furnace 5, and the entrance of the flue gas channel of the furnace , a flue is provided, and the flue is followed by a superheating section 6 and a supplementary combustion section 7. It should be understood that the superheating section 6 can also be replaced by a superheater, or the superheater is arranged in the flue, and the post-combustion section 7 includes a post-combustion burner, and the post-combustion burner is located in the flue.

[0073] The chamber of the economizer 4 is provided with a water pipe through which water is supplied and water inlets and outlets at both ends of the water pipe. The chamber is also provided with a flue gas inlet and a flue gas outlet. The water pipe exchanges heat with the flue gas in the chamber th...

Embodiment 2

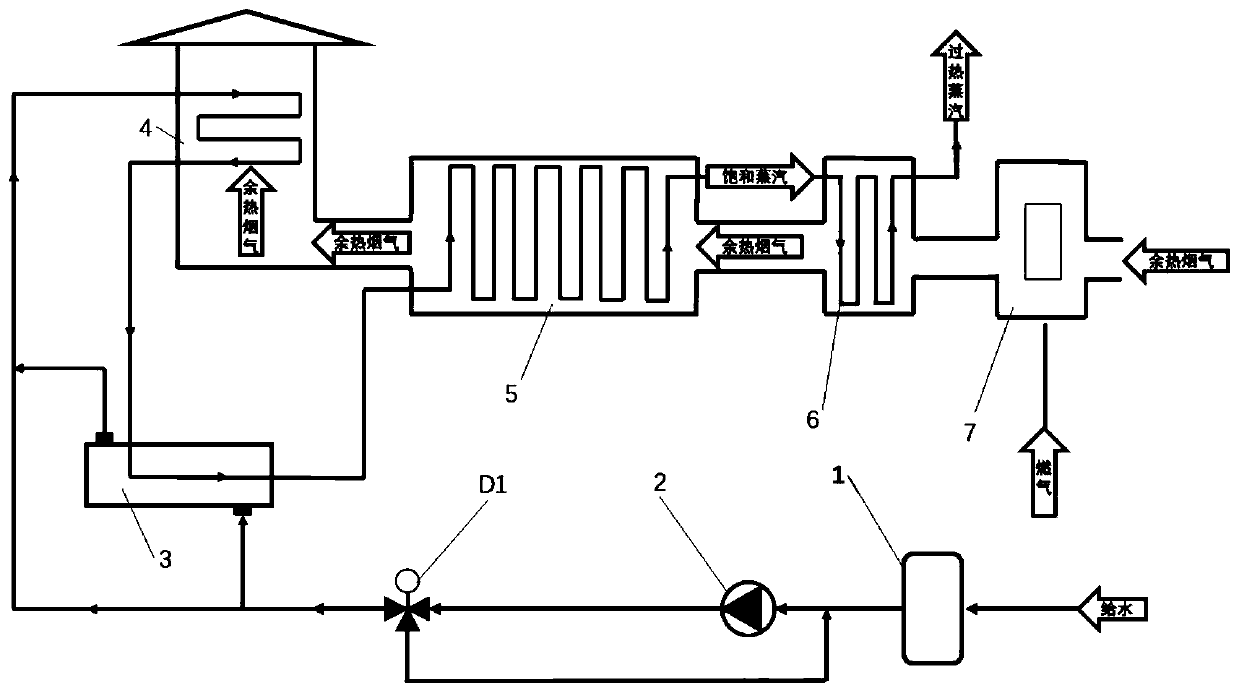

[0084] refer to figure 2 And embodiment 1, this embodiment provides a system for producing superheated steam, including water supply equipment 1 , pressurization equipment 2 , feedwater preheater 3 , economizer 4 , and furnace 5 .

[0085] The water supply equipment 1 includes a water supply pipeline for providing demineralized water. The pressurization equipment 2 is located on the water supply pipeline for pressurizing the demineralized water. Downstream of the pressurization equipment, the water supply pipeline is divided into a first water supply branch and a second water supply A branch, the first feedwater branch passes through the feedwater preheater 3 , and the part of the first feedwater branch inside the feedwater preheater 3 forms a first channel. The first feedwater branch and the second feedwater branch merge downstream of the feedwater preheater 3 and enter the water inlet of the economizer 4 together.

[0086] The water outlet of the economizer 4 is connected ...

Embodiment 3

[0091] In this embodiment, the flue gas comes from a gas turbine. The gas consumption of a 6630kW gas turbine of a certain brand is 2059Nm 3 / h, power generation efficiency is 32.2%, according to gas calorific value 35.5MJ / Nm 3 Calculated, including mechanical loss and other irreversible losses, there are 13766kWh (67.8%) of energy per hour that cannot be effectively utilized.

[0092] Taking the steam data required for heavy oil production in an oilfield in Xinjiang as an example, the steam demand is 10MPa high-pressure saturated steam. The flue gas waste heat steam injection boiler of this application is matched with the 6630kW gas turbine of this brand. The 505°C high temperature flue gas generated by the gas turbine power generation has a flow rate of 93153kg / h and enters the furnace of the flue gas supplementary combustion type waste heat steam injection boiler of this application. Initially The feed water temperature is 20°C, and the exhaust gas temperature of the econ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com