Pressurizing stacked disc filter

A filter and stacking disc technology, applied in the field of pressurized stacking disc filters, can solve the problems of inability to filter out extremely fine-grained coal particles, occupying a large space, difficult to maintain, etc., to achieve stable air pressure and reduce cracking and damage. , good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

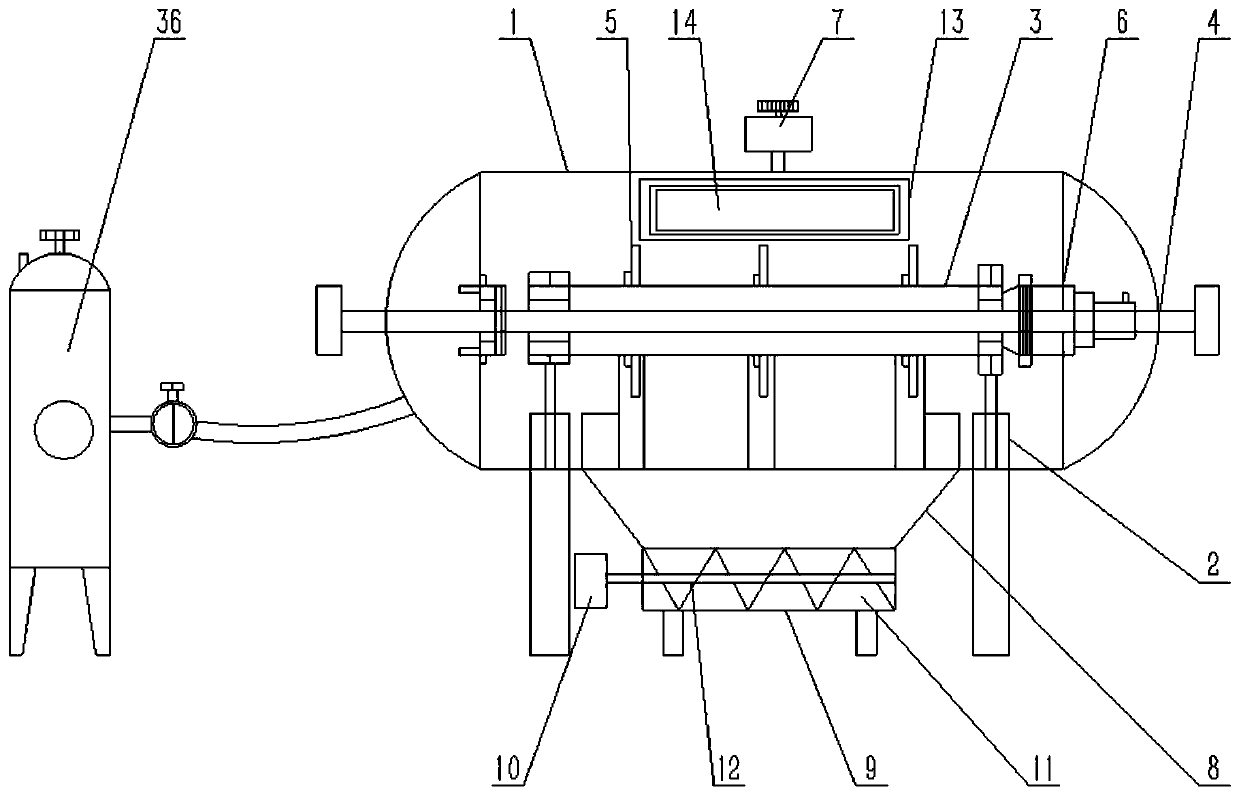

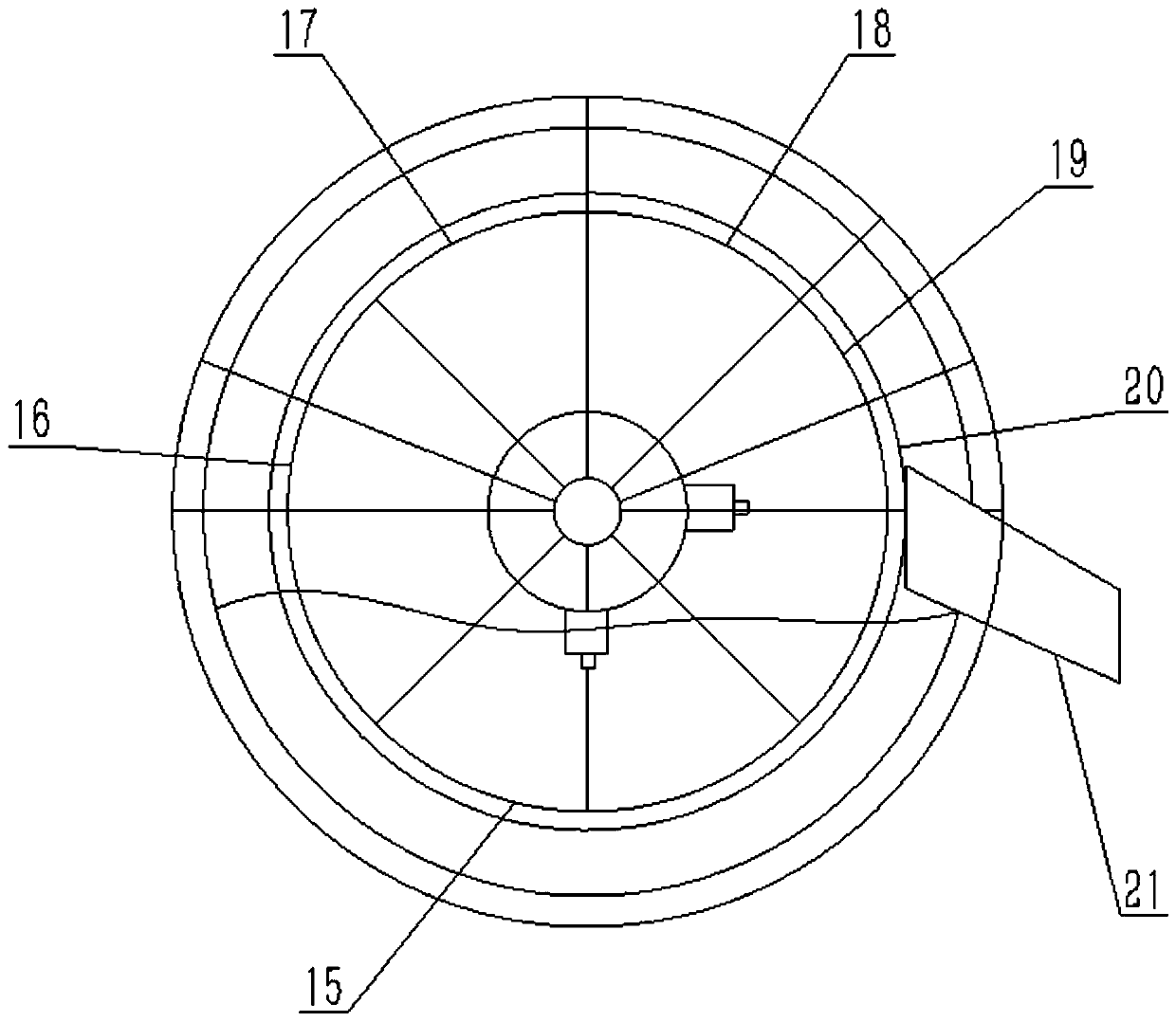

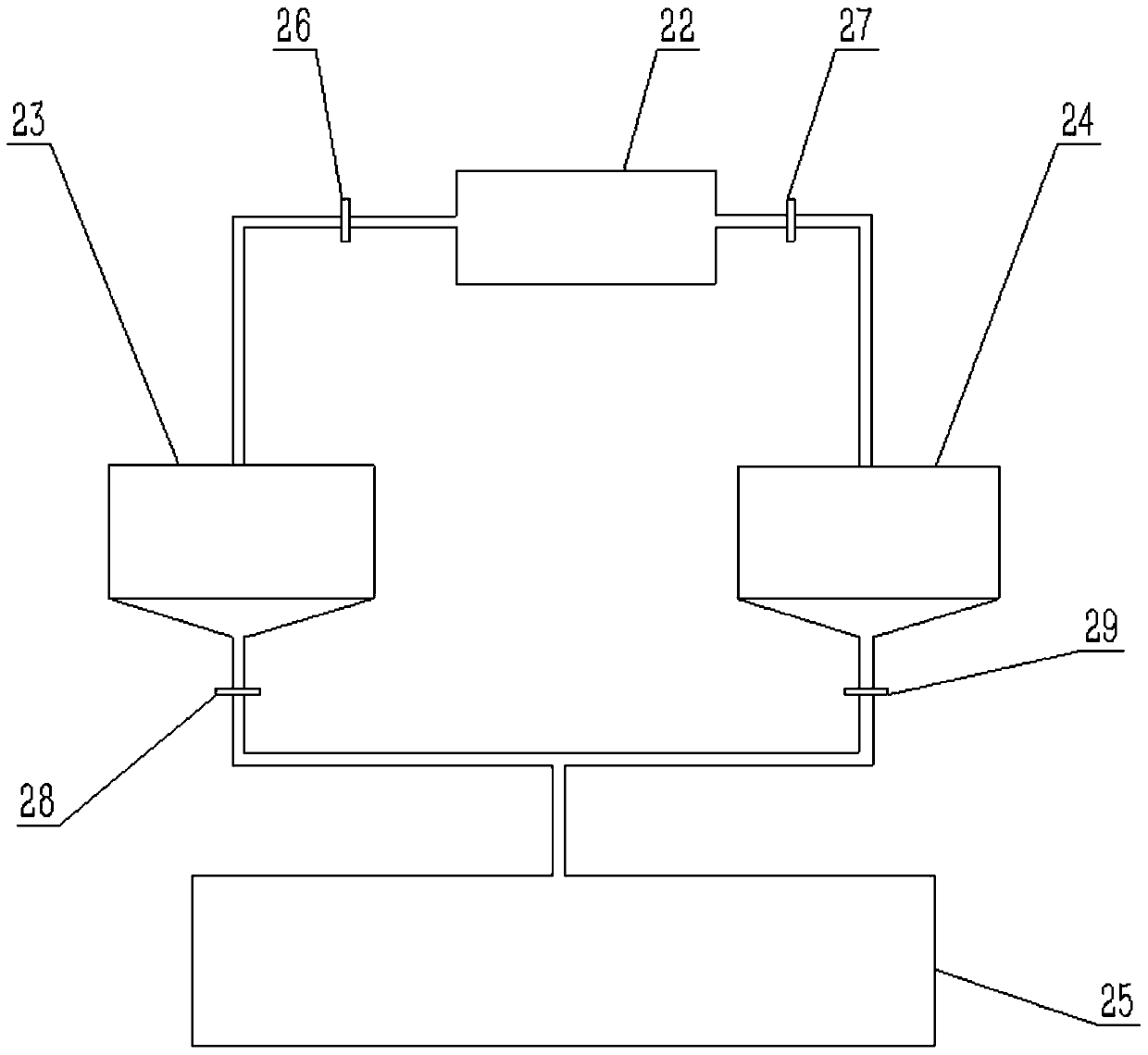

[0024] In conjunction with the accompanying drawings, a pressurized disc filter of the present invention is further described, and the present invention is further described in detail below in conjunction with the embodiments:

[0025] A pressurized stacked disc filter, including a pressurized chamber 1, a support frame 2 is arranged in the pressurized chamber 1, a slurry tank 3 is fixed on the support frame 2, and a main shaft 4 is horizontally and rotatably installed on the support frame 2 , a plurality of filter discs 5 are fixedly installed on the main shaft 4, a first motor 6 is installed on one end of the main shaft 4, the first motor 6 drives the main shaft 4 to rotate, a safety valve 7 is installed on the top of the pressurized chamber 1, and a bottom of the pressurized chamber 1 is provided There is a buffer bin 8, and a discharge device 9 is arranged below the buffer bin 8. The discharge device 9 includes a second motor 10, a discharge bin 11, and a screw rod 12. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com