A diesel ultra-deep desulfurization device and a diesel hydrogenation reaction system

A hydrogenation reaction and deep desulfurization technology, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrocarbon oil treatment products, etc., can solve the problems of low sulfur adsorbent, easy penetration, complex regeneration system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

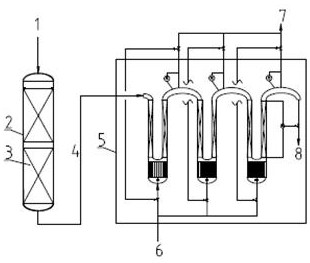

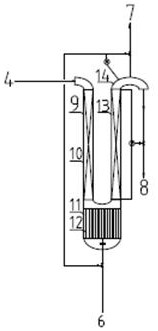

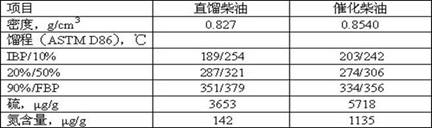

[0051] Attached figure 1 The method, wherein the amount of hydrogen in the hydrogenation reactor is 0.405% of the mass of the raw material oil (the sum of fresh raw material oil and circulating oil), and the reaction conditions of the fixed bed hydrogenation reactor are as follows: the reaction temperature is 310-355 ℃, the reaction pressure is 6.0MPaG, and the liquid hourly volume space velocity is 4.5h -1 . The sulfur content in the feedstock oil after fixed-bed hydroupgrading was 576 μg / g.

[0052] The feedstock oil after fixed-bed hydrotreating enters the deep hydrodesulfurization unit, which includes three “U-shaped” tubular reactors connected in series, in which the membrane tube micro-disperser disperses hydrogen into 50nm hydrogen bubbles, nano The amount of hydrogen injected per micron is 0.128% of the mass of the raw oil ("U-shaped" tubular reactor feed); the reaction conditions in the hydrogenation reaction section are as follows: the reaction temperature is 310-3...

Embodiment 2

[0055] Attached figure 1 The method, wherein the amount of hydrogen in the hydrogenation reactor is 0.389% of the mass of the raw material oil (the sum of fresh raw material oil and circulating oil), and the reaction conditions of the fixed bed hydrogenation reactor are as follows: the reaction temperature is 320-360 ℃, the reaction pressure is 6.0MPaG, and the liquid hourly volume space velocity is 5.0h -1 . The sulfur content in the feedstock oil after fixed-bed hydroupgrading was 355 μg / g.

[0056] The feedstock oil after fixed-bed hydrotreating enters the deep hydrodesulfurization unit, which includes five “U-shaped” tubular reactors connected in series in sequence, in which the membrane tube microdisperser disperses hydrogen into 500nm hydrogen bubbles, and the nano The amount of hydrogen injected per micron is 0.152% of the mass of raw oil ("U-shaped" tubular reactor feed); the reaction conditions in the hydrogenation reaction section are as follows: the reaction tempe...

Embodiment 3

[0059] Attached figure 1 The method, wherein the amount of hydrogen in the hydrogenation reactor is 0.402% of the mass of the raw material oil (the sum of fresh raw material oil and circulating oil), and the reaction conditions of the fixed bed hydrogenation reactor are as follows: the reaction temperature is 320-360 ℃, the reaction pressure is 6.0MPaG, and the liquid hourly volume space velocity is 5.0h -1 . The sulfur content in the feedstock oil after fixed-bed hydroupgrading was 47 μg / g.

[0060] The feedstock oil after fixed-bed hydrotreating enters the deep hydrodesulfurization device, which includes seven "U-shaped" tubular reactors connected in series, in which the membrane tube microdisperser disperses hydrogen into 50nm hydrogen bubbles, and the nano The amount of hydrogen injected per micron is 0.164% of the mass of the feedstock oil (feed to the "U-shaped" tubular reactor); the reaction conditions in the hydrogenation reaction section are as follows: the reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com