Dust collection polar plate for plasma organic waste gas treatment

An organic waste gas and plasma technology, applied in electrode structure, electrostatic separation, electrode cleaning, etc., can solve the problems of poor particle treatment effect, detachment from the attraction of the electrode plate, reducing the stability of plasma treatment equipment, etc., and achieves high treatment efficiency. Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

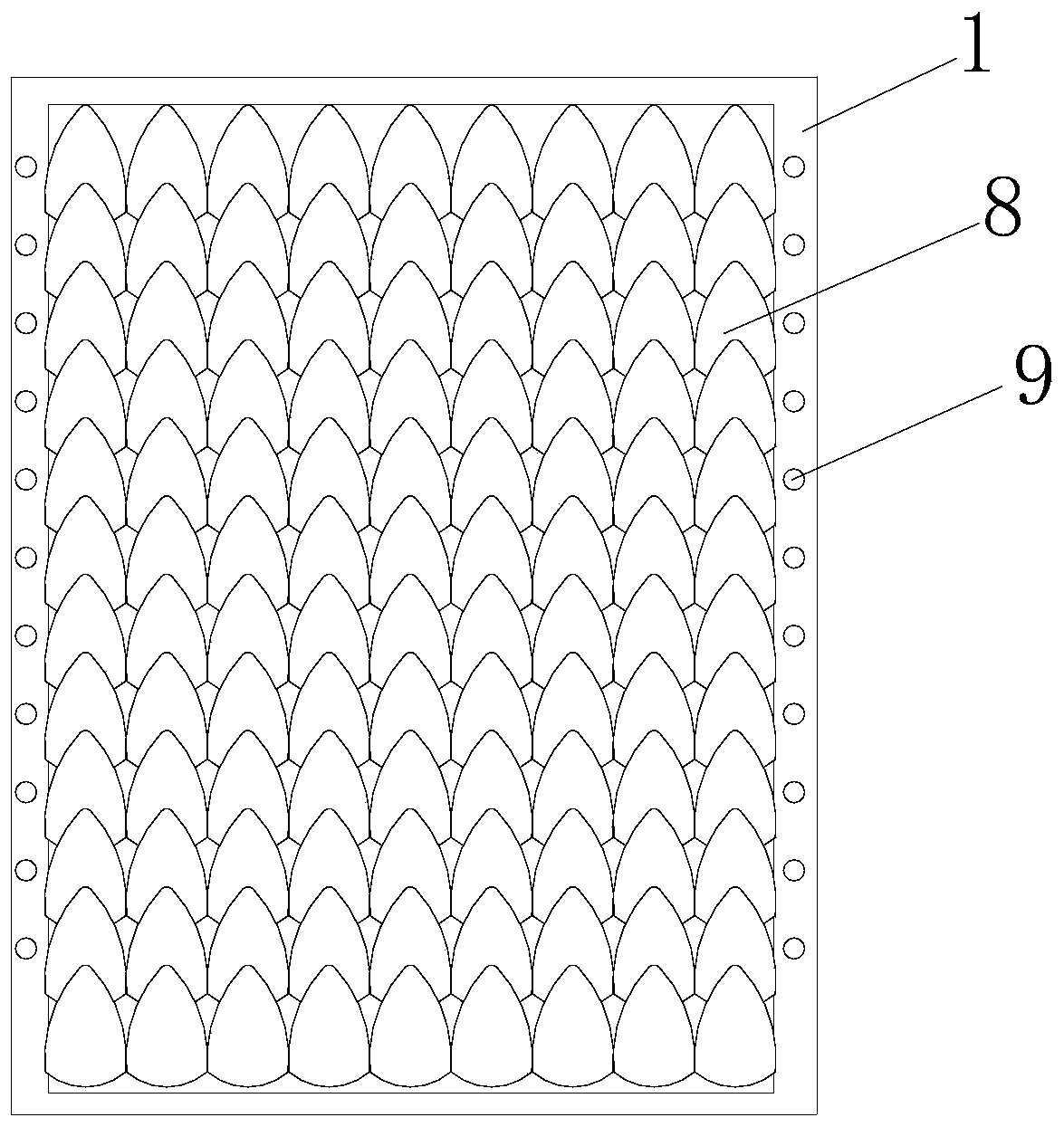

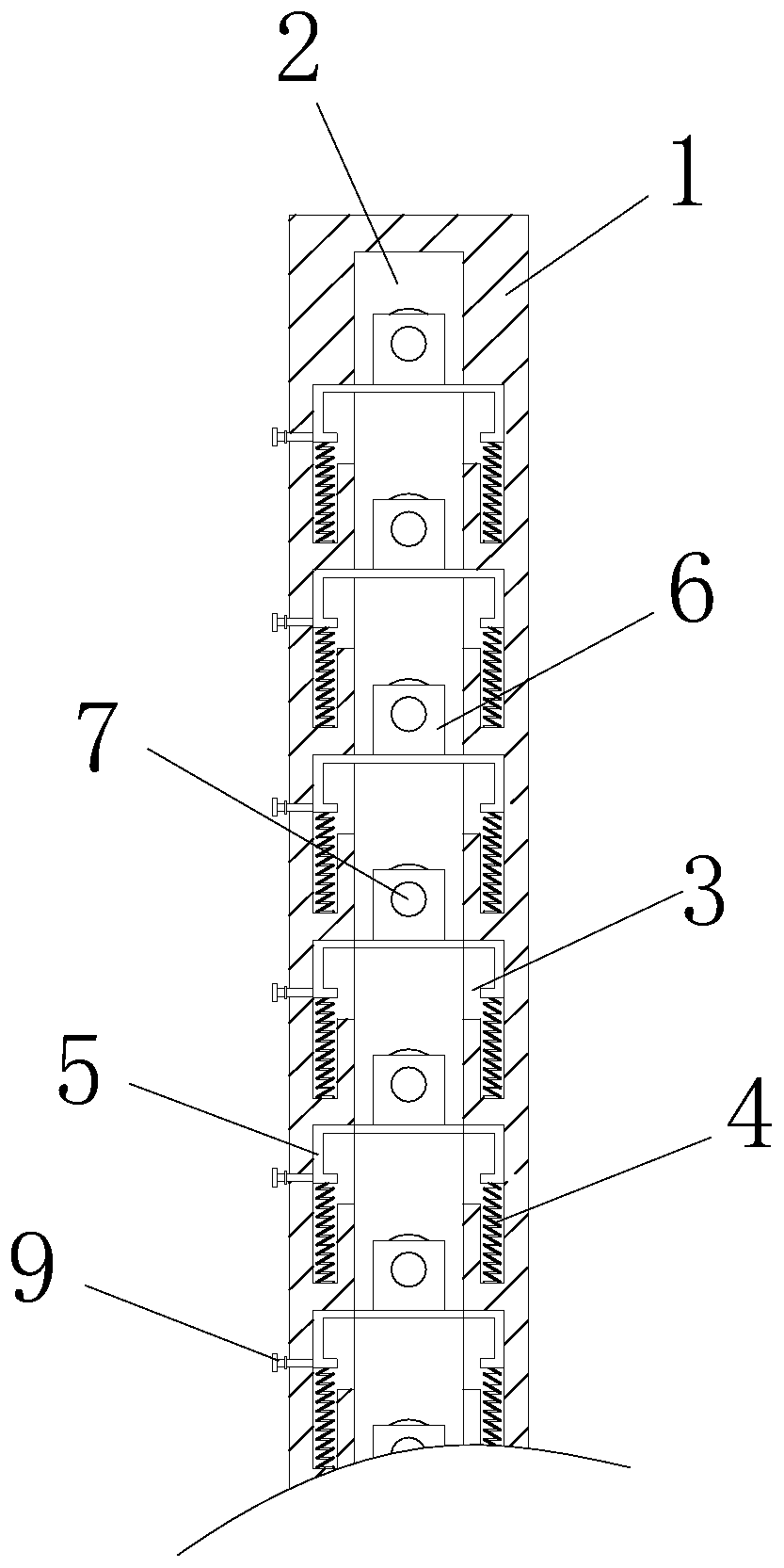

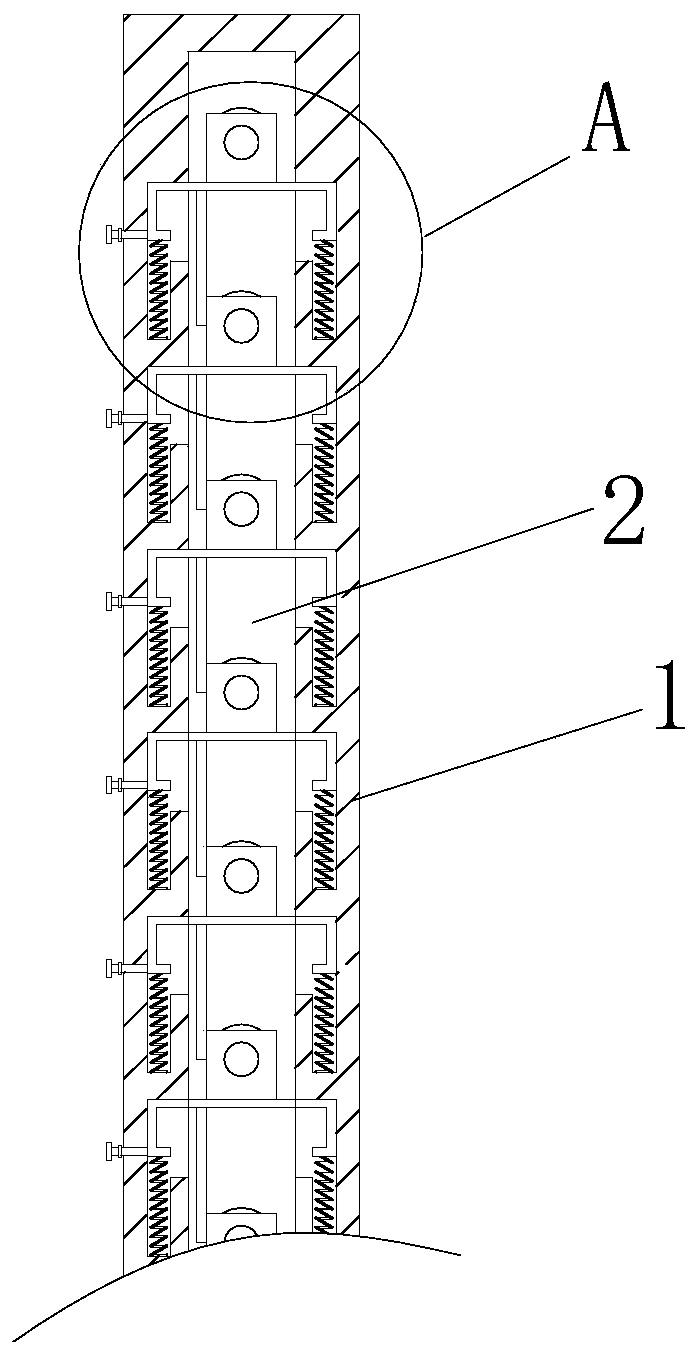

[0032] Example 1: Please refer to Figure 1-2, The present invention proposes a dust collector plate for plasma organic waste gas treatment, comprising a frame body 1, the frame body 1 is a rectangular body with a hollow center, and the inner walls of the left and right sides of the frame body 1 are provided with sliding holes 2. The sliding holes 2 is a rectangular hole, the front and rear inner walls of the two sliding holes 2 are provided with thirteen groups of chutes 3, and the number of each group of chutes 3 is two and located on the front and rear inner walls of the sliding holes 2, respectively, and the chutes 3 are inverted L. The inner wall of the bottom surface of the chute 3 is fixedly connected with a return spring 4, and the unfixed end of the return spring 4 in each set of chute 3 is fixedly connected with a movable plate 5. The shape of the movable plate 5 is a C-shaped body, and the movable plate 5 The top surface is provided with a rectangular protrusion 6, ...

Embodiment 2

[0033] Example 2: Please refer to Figure 3-4 , On the basis of the first embodiment, the bottom surface of the movable plate 5 is fixedly connected with a frosted plate 10, the frosted plate 10 and the rectangular protrusion 6 are staggered left and right, and the frosted plate 10 is attached to the front side of the circular rod 7 under the movable plate 5, and the frosted The plate 10 has two functions. First, it is attached to the round rods 7 in the next row, so as to limit the rotation of the round rods 7. When the electrode sheet 8 is pushed by the rising exhaust gas and its own weight changes, it can also keep the electrode sheet 8. Secondly, when the electrode sheet 8 is lowered due to the accumulation of particles, the matte plate 10 is attached to the round rod 7 to drive the electrode sheet 8 in the next row to be in an unfolded state, so that the concave surface of the electrode sheet 8 is the same as the one in the previous row. The positions of the electrode she...

Embodiment 3

[0034] Example 3: Please refer to Figure 5 , On the basis of the first embodiment, the electrode sheet 8 is in the shape of scales, and the scale-shaped electrode sheet 8 can reduce the frictional force generated when contacting with the exhaust gas, thereby reducing the degree of friction on the electrode sheet 8 after being in contact with the exhaust gas for a long time. The back side of the sheet 8 is concave, the back side of the electrode sheet 8 is fixedly connected with an insulating pad 11, the shape and size of the insulating pad 11 are adapted to the electrode sheet 8, and the back side of the insulating pad 11 is fixedly connected with a slideway plate 12. The shape of the slide plate 12 is a fan-shaped body, and the bottom end of the sliding plate and the insulating pad 11 have an included angle of 30 degrees. Provides acceleration, thereby accelerating particle removal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com