Screening device for liquid organic fertilizer

A screening device and organic fertilizer technology, which is applied in the fields of screening, application, and solid separation, can solve the problems of low screening efficiency and poor screening effect of tung tree shells, etc., to improve the screening effect, ensure smoothness, and accelerate separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

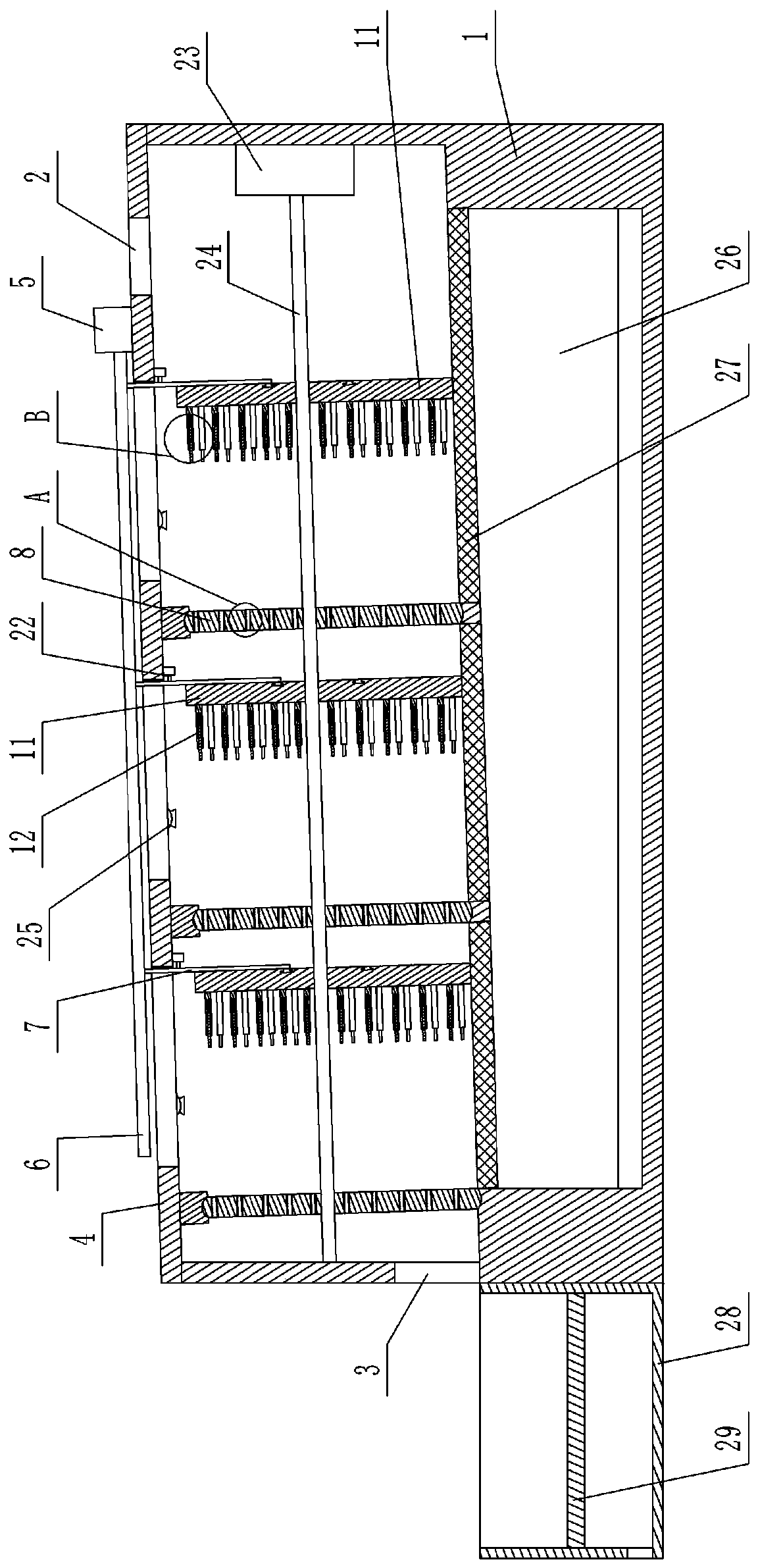

[0041] Screening device for liquid organic fertilizer, combined with attached figure 1 As shown, it is mainly composed of a box body 1, a cover plate 4, a material inlet 2, a material outlet 3, several sieve plates 8, several push plates 11, a motor 23, a rotating shaft 24, a pushing unit, and a sieving unit.

[0042] The top surface of the bottom of the box body 1 is inclined from the upper right to the lower left, and the inclination angle is 15-45°. The cover plate 4 is set on the top of the box body 1, and the cover plate 4 is arranged parallel to the top surface of the bottom of the box body 1; The 3 places of the discharge port are fixedly connected with a collecting tank 28, the left side of the upper part of the collecting tank 28 is equipped with a second nozzle, the middle part of the collecting tank 28 is clamped with a drainage net 29, and the bottom left side of the collecting tank 28 is provided with a drain.

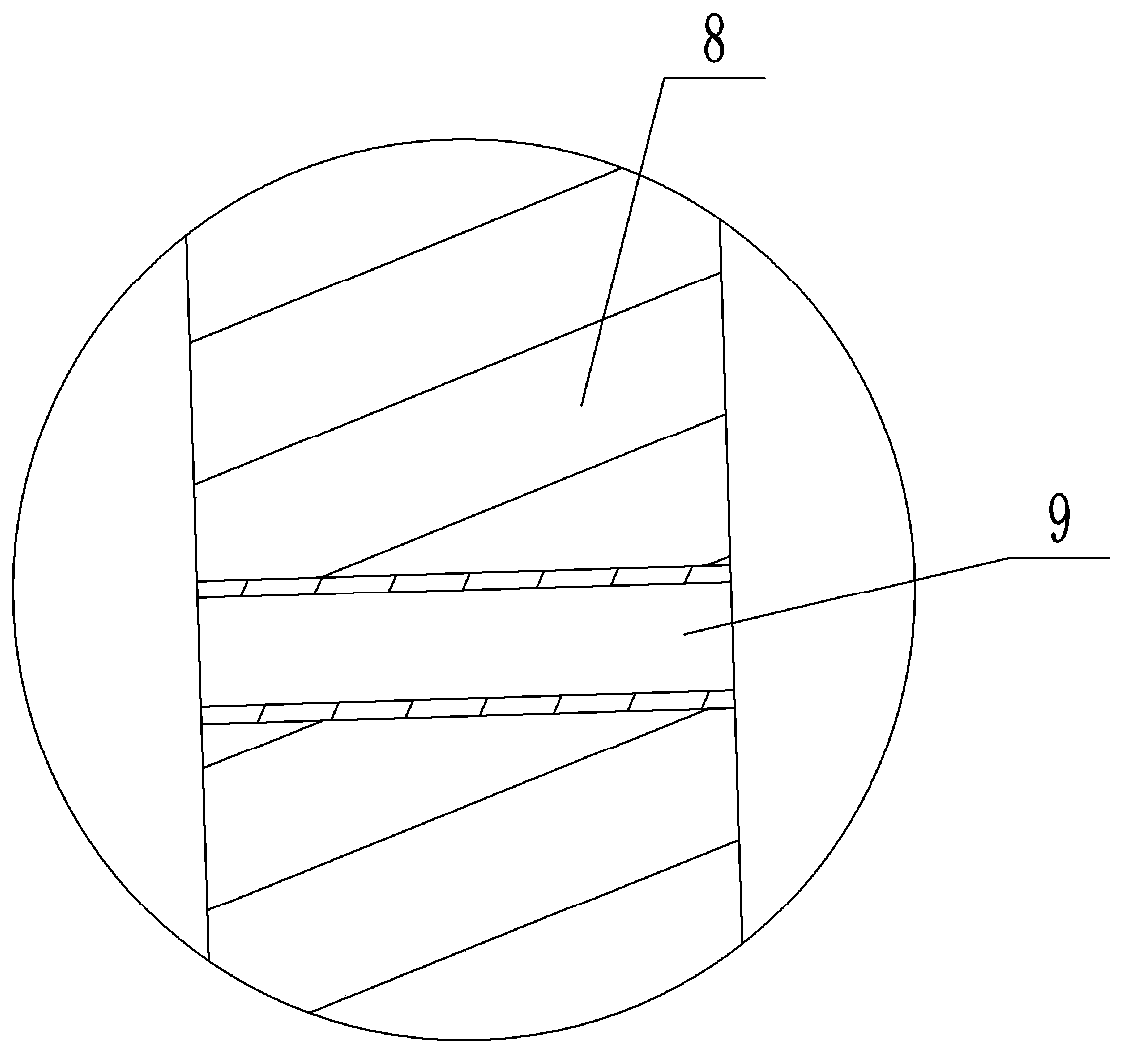

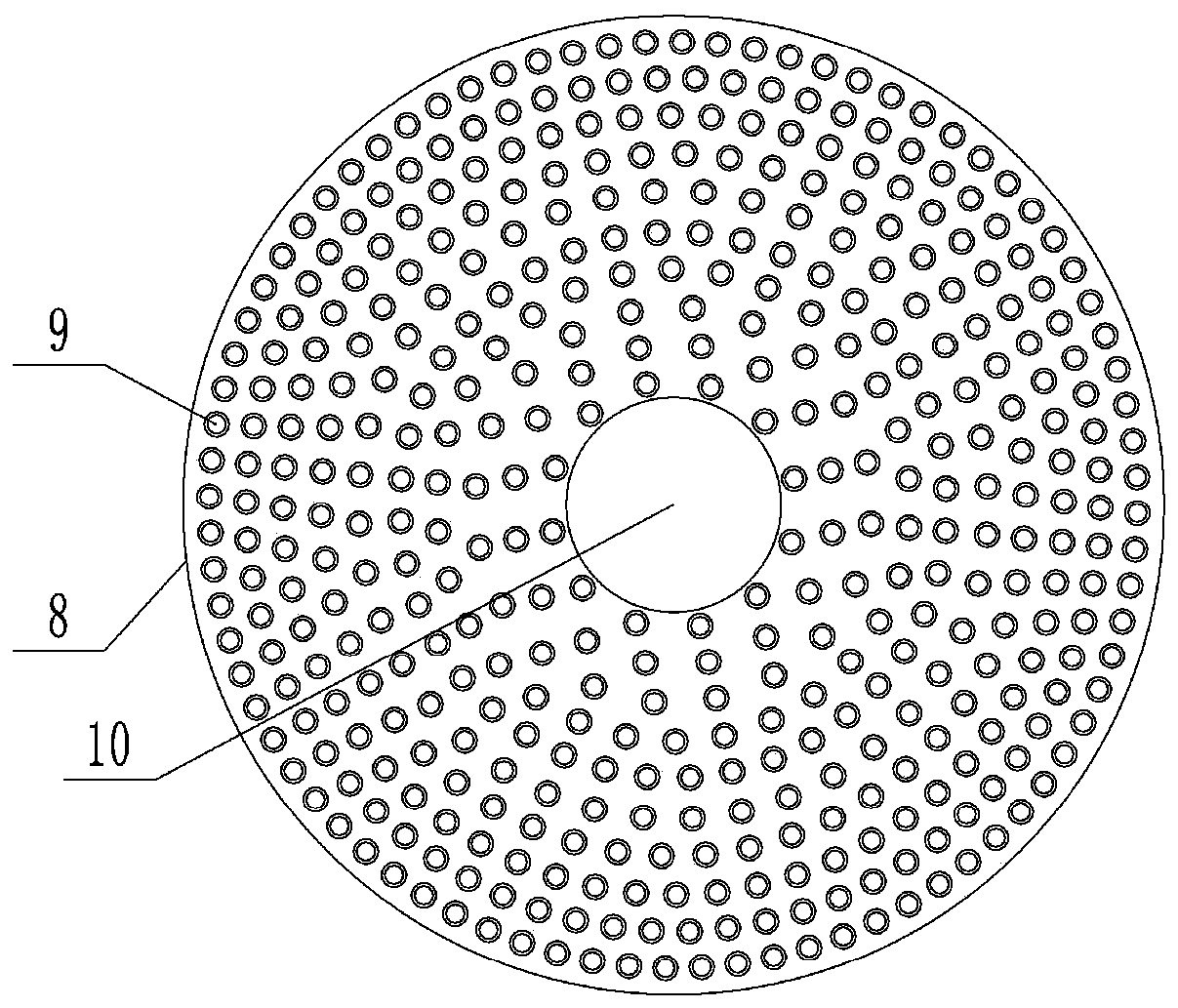

[0043] Several sieve plates 8 are arranged sequential...

Embodiment 2

[0057] The difference between this embodiment and embodiment 1 is that: Figure 7 As shown, the bottom of the connecting rod 7 is provided with two L-shaped struts 30, and the two struts 30 are welded with a T-shaped second slider, and the second slider is slidably connected in the annular limiting groove 15; The top side of the rod 7 is welded with reinforcing ribs, and the end of the reinforcing ribs away from the connecting rod 7 is welded on the push rod 6 .

[0058] By adding two struts 30 and two second sliders, the connecting rod 7 exerts more force on the push plate 11, so that the pushing effect of the connecting rod 7 on the push plate 11 is more stable, and the connecting rod 7 is extended. service life. The reinforcing rib can enhance the stability of the connecting rod 7, reduce the probability of the connecting rod 7 being broken due to driving the push plate 11 to move, and prolong the service life of the connecting rod 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com