An optical polyester film

An optical polyester film and polyester film technology, applied in the field of polyester film, can solve the problems of low yield rate of deep-processed products, poor product appearance, and high production cost, so as to improve the yield rate of semi-finished products and finished products, improve yield rate, The effect of increased compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

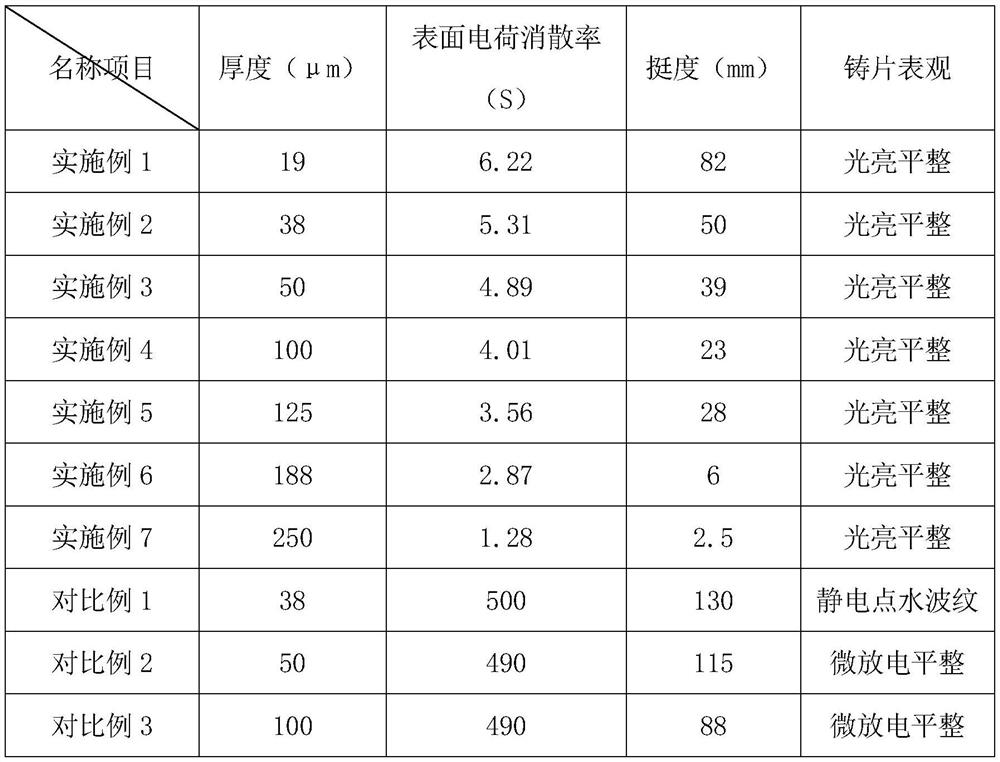

Examples

preparation example Construction

[0035] The preparation method of modified polyester I is:

[0036] Select film-grade bright polyethylene terephthalate (PET) slices with an intrinsic viscosity of 0.77dl / g~0.87dl / g as the base material, and then mix N,N-bishydroxyethyl lauramide and 2, 6-dihydroxybutyl naphthalate-5-sulfonimide potassium is mixed according to the mass ratio of 1:1~1:6, and sent to the twin-screw extruder together, and then vacuumized, after spinning and cooling , pelletizing and drying to obtain the modified polyester I of the present invention, the intrinsic viscosity of the modified polyester I is 0.66dl / g~0.76dl / g. The modified polyester I of the present invention is prepared by twin-screw extrusion granulation instead of synthesis. The main reason is that the esterification and polycondensation process will destroy polar groups such as dihydroxy groups and affect its effect.

[0037] The preparation method of modified polyester II is:

[0038] ① Add the required dibasic acid, diol, catal...

Embodiment 1

[0050] Preparation of modified polyester I:

[0051] Select film-grade bright polyethylene terephthalate (PET) slices with an intrinsic viscosity of 0.83dl / g as the base material, and then mix N,N-bishydroxyethyl lauramide and 2,6-naphthalene dicarboxylic acid Potassium dihydroxybutyl ester-5-sulfonimide is mixed according to the mass ratio of 1:1, and sent to the twin-screw extruder together, and then vacuumized, and is obtained by spinning, cooling, pelletizing, and drying. The modified polyester I described in the present invention has an intrinsic viscosity of 0.73dl / g.

[0052] Preparation of modified polyester II:

[0053] According to the molar ratio of terephthalic acid and ethylene glycol 1:1.3, the addition amount of ethylene glycol antimony is 180ppm, the addition amount of trimethyl phosphate is 35ppm, and the mass ratio of 1:1 has been dispersed by SG-A1821 and DL-411DF Magnesium acetate whiskers with a diameter of 0.02 μm and a length of 0.5 μm and potassium ti...

Embodiment 2

[0056] Preparation of modified polyester I:

[0057] Select film-grade bright polyethylene terephthalate (PET) slices with an intrinsic viscosity of 0.87dl / g as the base material, and then mix N,N-bishydroxyethyl lauramide and 2,6-naphthalene dicarboxylic acid Potassium dihydroxybutyl ester-5-sulfonimide is mixed according to the mass ratio of 1:1, and sent to the twin-screw extruder together, and then vacuumized, and is obtained by spinning, cooling, pelletizing, and drying. The modified polyester I described in the present invention has an intrinsic viscosity of 0.76dl / g.

[0058] Preparation of modified polyester II:

[0059] According to the molar ratio of terephthalic acid and ethylene glycol 1:1.3, the addition amount of ethylene glycol antimony is 180ppm, the addition amount of trimethyl phosphate is 35ppm, and the mass ratio of 2:1 is satisfied. SG-A1821 and DL-411DF Magnesium acetate whiskers with a diameter of 0.05 μm and a length of 0.5 μm and potassium titanate w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com