Glass kiln upper and lower layer electrode propelling device and method

A glass furnace and propulsion device technology, applied in glass furnace equipment, glass manufacturing equipment, furnaces, etc., can solve problems such as unreachable, large propulsion error, and inability to meet the melting requirements of furnace glass liquid, so as to avoid dislocation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0035] The orientation words used in the examples such as "up, down, left, right, top, bottom" usually refer to the corresponding structure of the upper and lower electrode propulsion devices of the glass furnace under the use state of "up, down, left, right, top, bottom "; "front and rear" refer to the positional relationship relative to the glass furnace; "advancing direction" refers to the direction in which the furnace electrode is pushed from the outside to the inside relative to the glass furnace.

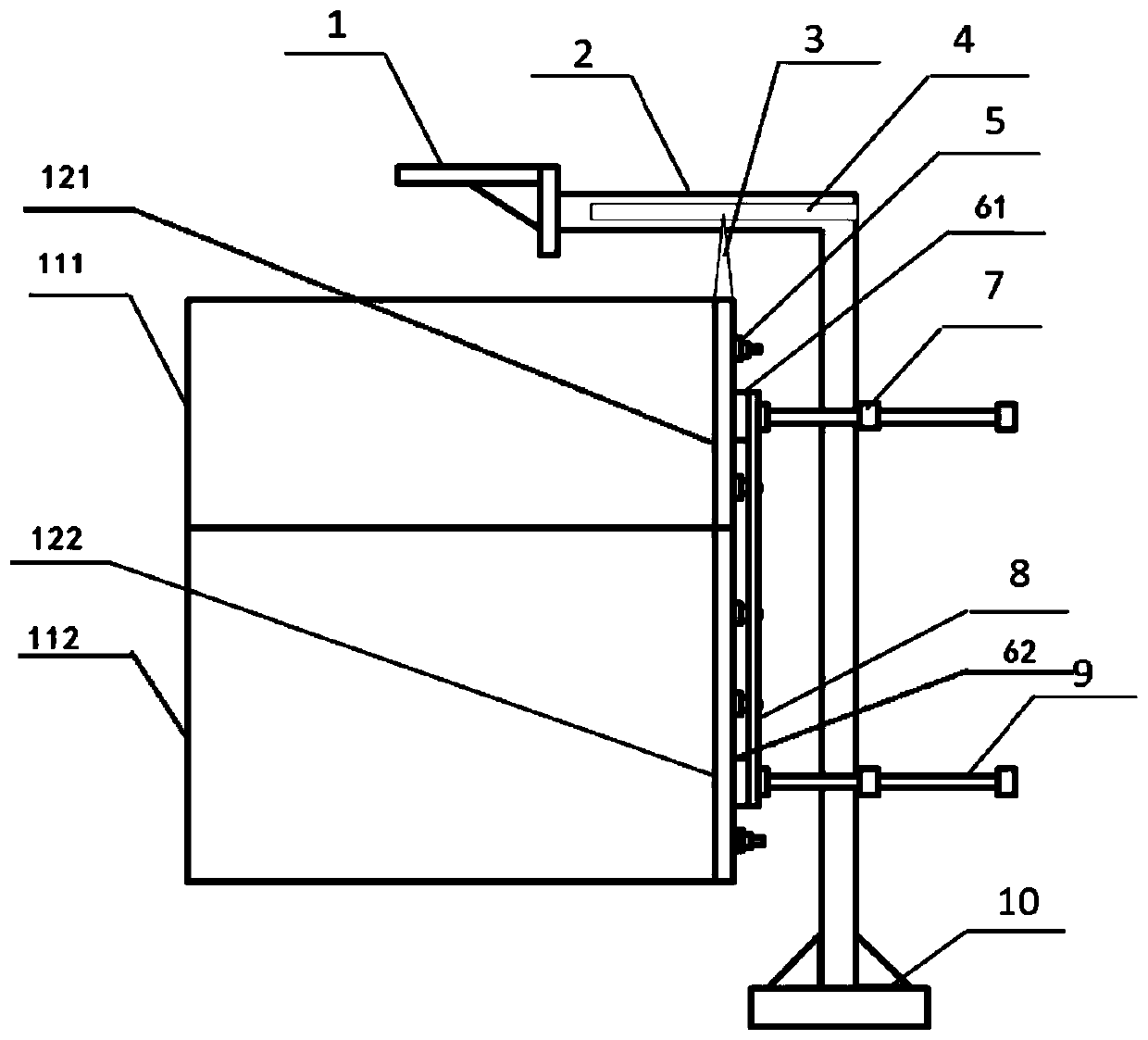

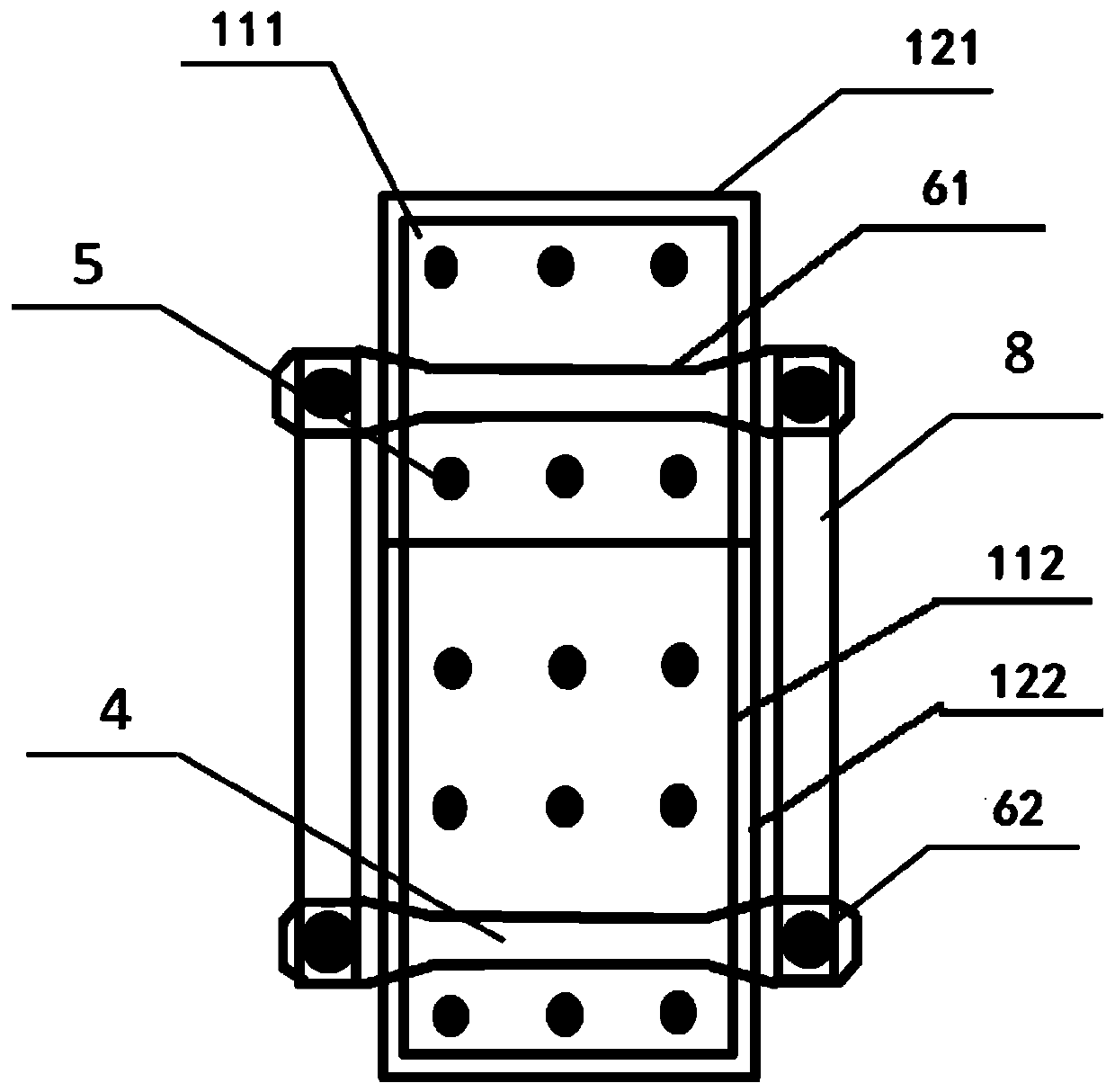

[0036] The invention relates to a propelling device and method for upper and lower electrodes of a glass furnace. Such as figure 1 with figure 2 As shown, the upper water cooling plate 121 and the lower water cooling plate 122 divide the kiln electrodes into upper and lower layers, the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com