MXene/graphene composite heat-conducting fluid and preparation method and application thereof

A graphene composite, heat-conducting fluid technology, applied in chemical instruments and methods, materials for heat exchange, etc., can solve the problems of low thermal conductivity of water, low heat transfer efficiency, affecting the efficiency of temperature control and crack prevention, and achieve good pumping. Good performance and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

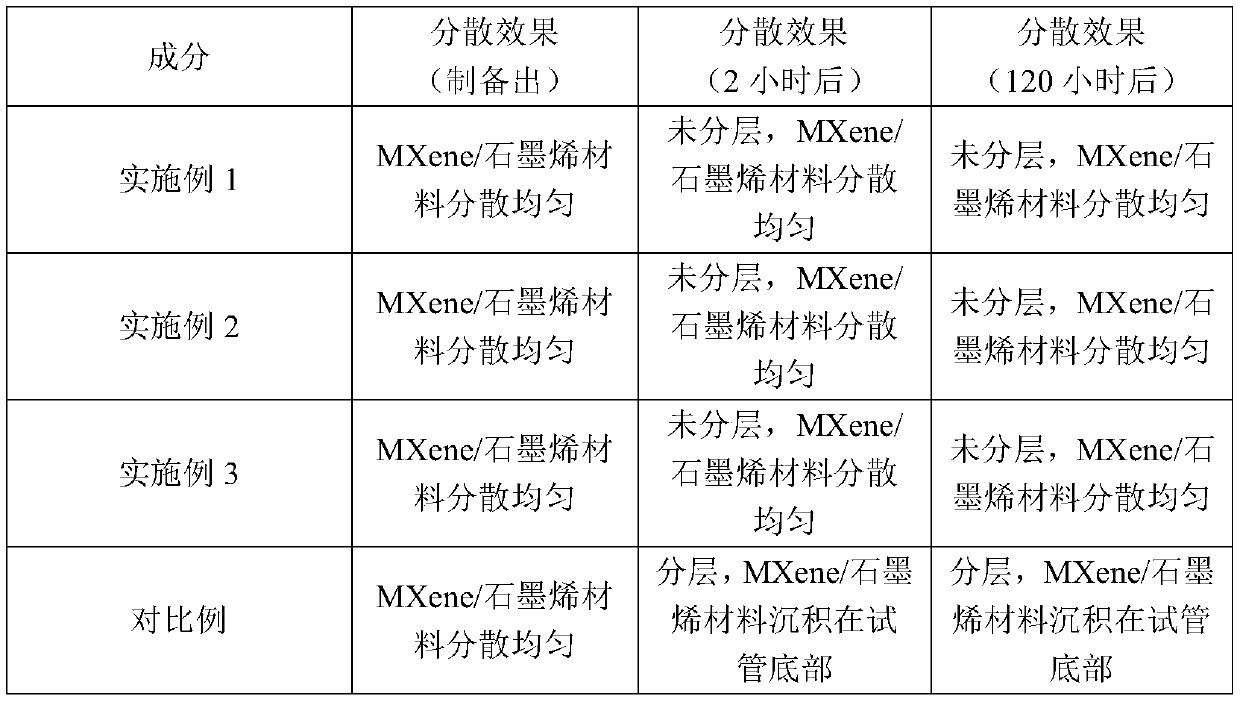

Embodiment 1

[0015] 0.1667g Ti 3 C 2 Tx, 0.3333g graphene and 0.5g sodium dodecylbenzenesulfonate were added to 49g water, stirred at a stirring rate of 600rpm for 30min and mixed evenly, and then ultrasonically dispersed for 60min to obtain uniformly dispersed and stable MXene / graphene heat transfer fluid. In the MXene heat-conducting fluid, MXene / graphene is 1%, MXene:graphene=0.5:1, sodium dodecylbenzenesulfonate is 1%, and water is 98%. Pass the MXene / graphene heat transfer fluid as the heat transfer medium into the cooling water pipe in the concrete for heat dissipation.

Embodiment 2

[0017] 0.1667g Ti 3 C 2 Tx, 0.3333g graphene and 0.5g hexadecyltrimethylammonium bromide were added to 49g water, stirred at a stirring rate of 600rpm for 30min, mixed evenly, and then ultrasonically dispersed for 60min to obtain uniformly dispersed and stable MXene / Graphene heat transfer fluid. In the MXene heat-conducting fluid, MXene / graphene is 1%, MXene:graphene=0.5:1, cetyltrimethylammonium bromide is 1%, and water is 98%. The MXene / graphene heat transfer fluid is used as a heat transfer medium to pass into the cooling water pipe in the concrete for heat dissipation.

Embodiment 3

[0019] 0.25g Ti 3 C 2 Tx, 0.25g graphene and 0.5g sodium dodecylbenzene sulfonate were added to 49g water, stirred at a stirring rate of 600rpm for 30min, mixed evenly, and then ultrasonically dispersed for 60min to obtain uniformly dispersed and stable MXene / graphene heat transfer fluid. In the MXene heat-conducting fluid, MXene / graphene is 1%, MXene:graphene=1:1, sodium dodecylbenzenesulfonate is 1%, and water is 98%. Pass the MXene / graphene heat transfer fluid as the heat transfer medium into the cooling water pipe in the concrete for heat dissipation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com