Device and method for remotely controlling gas production rate of coal-bed gas wells

A technology for remote control of coalbed methane wells, which is applied to wellbore/well valve devices, earthwork drilling and production, wellbore/well components, etc. It can solve problems such as labor costs, casing pressure changes, and inability to be adjusted in time. To achieve the effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

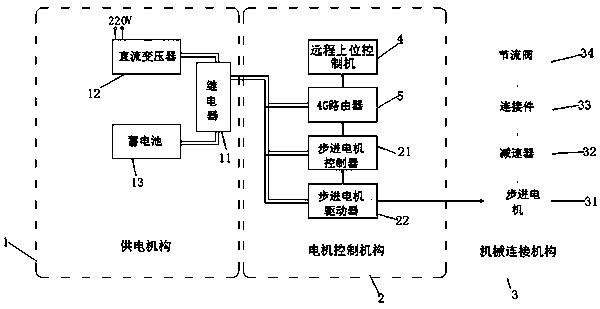

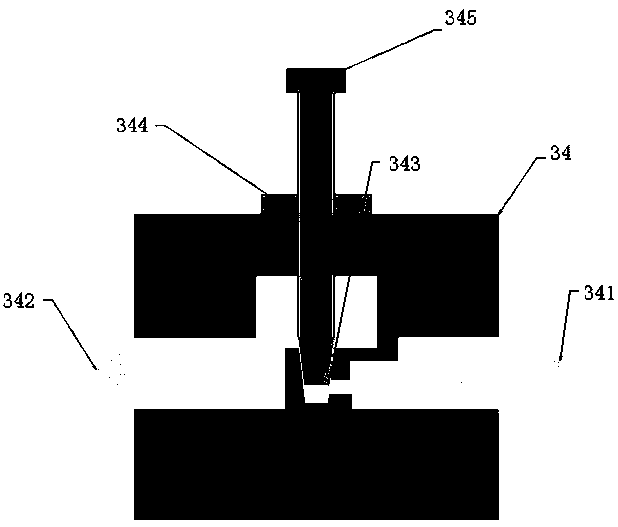

[0016] Such as figure 1 As shown, the device for remotely controlling the gas production of a coalbed methane well in the present invention includes: a power supply mechanism 1, a motor control mechanism 2, and a mechanical connection mechanism 3; 32, connecting piece 33 and throttle valve 34; gas inlet 341 and gas outlet 342 for the circulation of coal bed gas are arranged on the throttle valve 34, and a controllable cone 343 is set to extend into the interior from the through hole at the top of the throttle valve , the through hole is provided with a screw thread and a sealing ring 344, and the side wall of the controllable cone 343 is provided with threads, and the screw thread is matched with the thread to move rela...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap