Externally-wrapped friction block for high-speed train brake

A technology for high-speed trains and friction blocks, applied to friction linings, slack adjusters, mechanical equipment, etc., can solve the problems of outsourcing friction blocks and achieve the effects of reducing the risk of thermal fatigue, reducing weight, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings of the description.

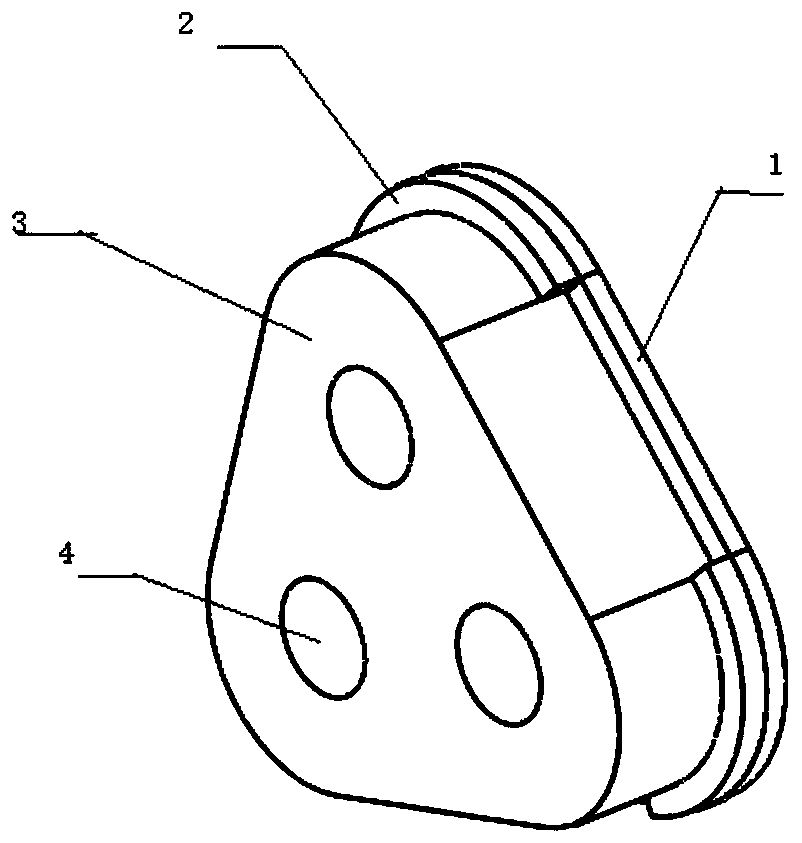

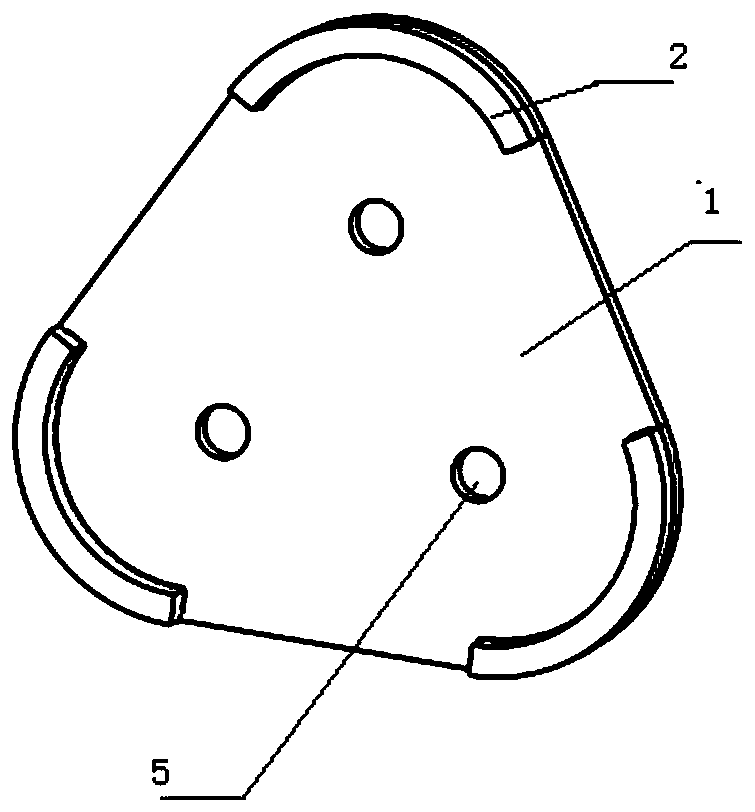

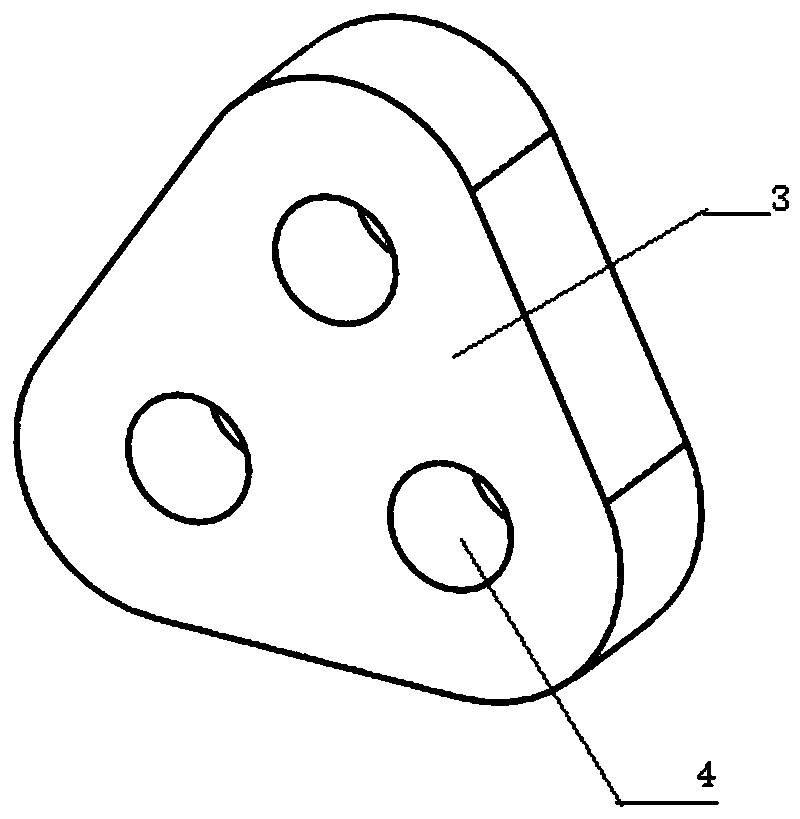

[0024] Such as Figure 1-5 As shown, the outsourced friction block for high-speed train brakes includes: friction block steel back bottom plate 1, friction block steel back arc claw 2, friction block compact 3, first through hole 4, second through hole 5; On a plane of the friction block steel back bottom plate 1, the friction block steel back arc-shaped claws 2 are arranged according to the distribution of each end with the center of the end face as the origin, and the second through hole 5 is vertically penetrated on the friction block steel back bottom plate 1, and the friction block A first through hole 4 matching the second through hole 5 is vertically penetrating through the green compact 3 , and the friction block green body 3 and the friction block steel back base plate 1 are formed by pressure sintering.

[0025] Fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com