An ultra-thin vapor chamber with gradient copper fiber capillary core mesh

A copper fiber and capillary core technology is applied in the field of ultra-thin vapor chambers to achieve the effects of improving mechanical strength, optimizing heat and mass transfer effects, and reducing tube wall thickness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

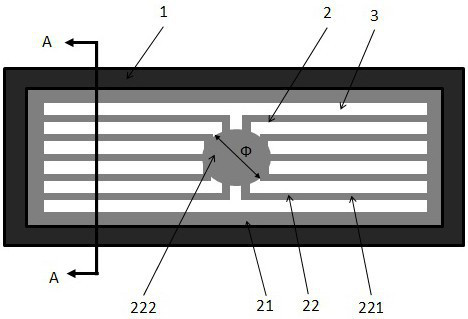

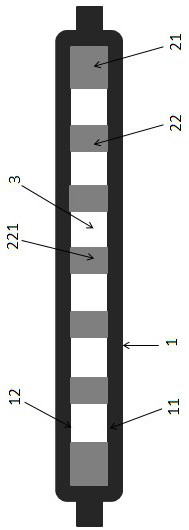

[0036] Such as figure 1 As shown, an ultra-thin vapor chamber with a gradient copper fiber capillary core mesh provided in this embodiment includes a board body 1 , and the board body 1 includes a first board body 11 and a second board body 12 . Wherein, the board body 1 is selected to have a length of 80 mm, a width of 60 mm, and a board wall thickness of 0.4 mm. figure 2 for figure 1 A cross-sectional view of an ultra-thin vapor chamber with a gradient copper fiber capillary mesh along line A-A shown.

[0037] In this embodiment, a copper fiber capillary core mesh 2 is provided between the inner surfaces of the first plate body 11 and the second plate body 12 . The first plate body 11 presses downward to form a concave cavity area, and the second plate body 12 presses upward to form a convex cavity area.

[0038]A steam channel 3 is formed between the first plate body 11 and the second plate body 12 and the copper fiber capillary core net 2 . The copper fiber capillar...

Embodiment 2

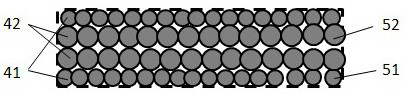

[0042] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, there are multiple groups of internal straight-edged capillary cores 221 in the ultra-thin vapor chamber, and the width Y of the steam channel 3 is kept at 3-8mm. In some cases, according to the specific heat dissipation space and requirements, the number of internal straight-edged capillary cores 221 is increased, and the width of the ultra-thin vapor chamber is increased. This design is a linear extension of the original design. Under the same thickness of the chamber, the heat transfer effect can be improved by increasing the width of the chamber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com