Preparation method of high-temperature surface source radiation source

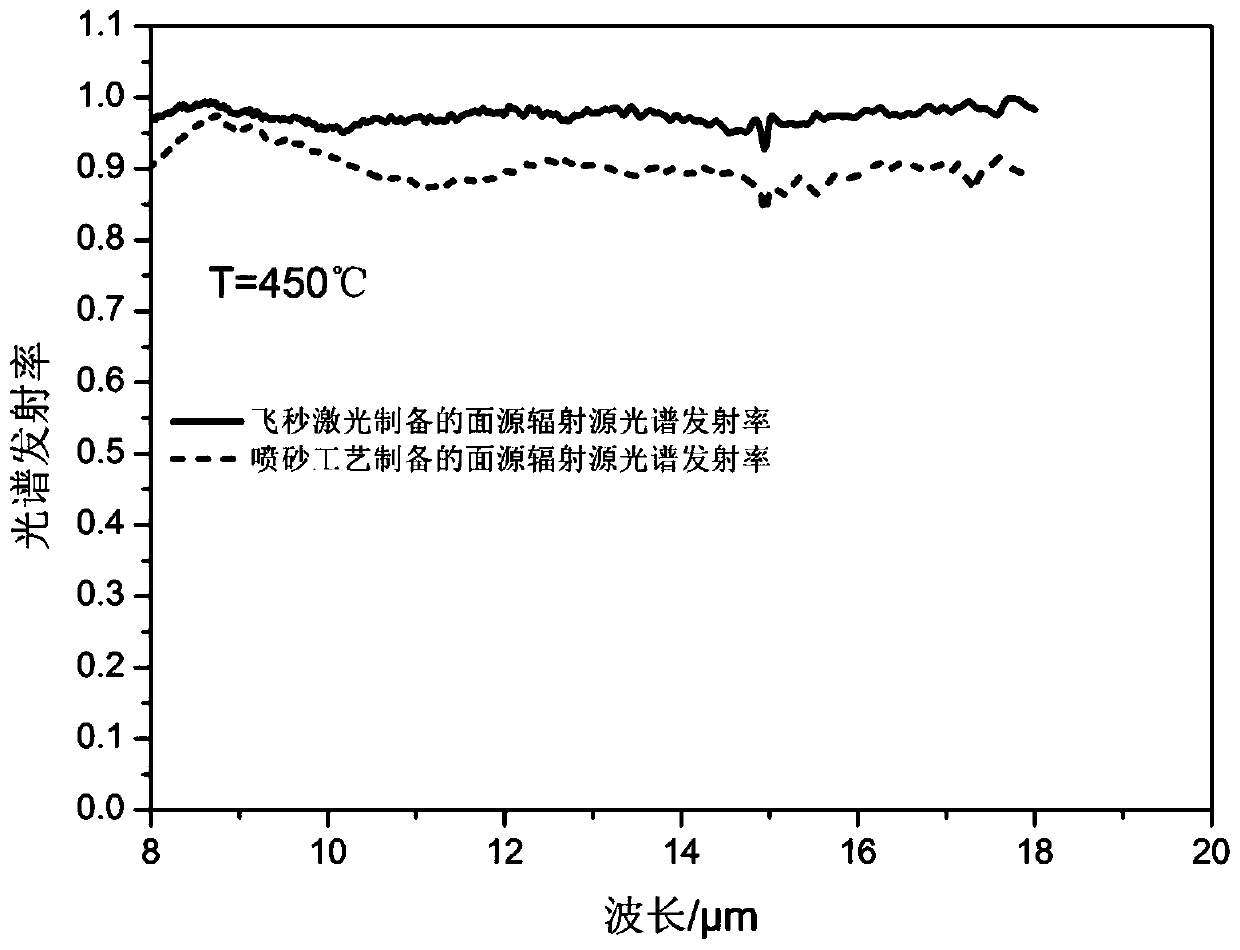

A radiation source and high-temperature surface technology, which is applied in the field of thermal radiation measurement, can solve the problems that the surface source radiation source cannot meet the emissivity requirements, and achieve precise and controllable laser parameters and translation stage parameters, high process repeatability, and improved optical efficiency. absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a high-temperature surface source radiation source, comprising the following steps in an embodiment of the method:

[0025] Step 1: Select an aluminum material as the surface source radiation source substrate, the thickness of the aluminum substrate material is 10mm, and clean the surface of the substrate.

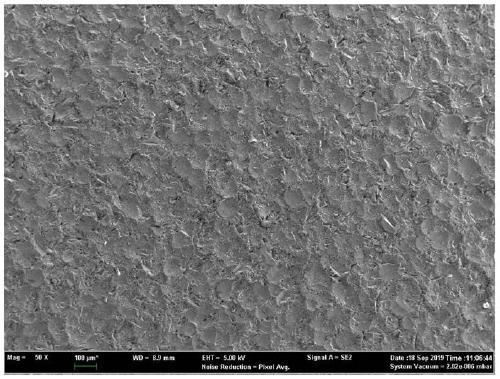

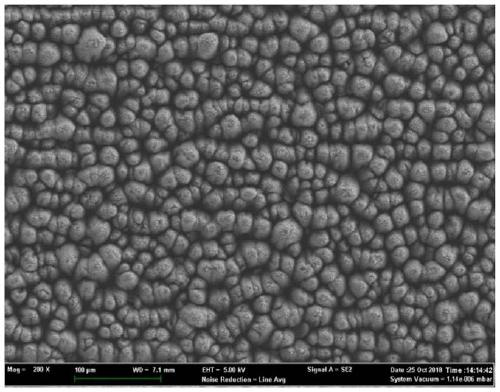

[0026] Step 2: Prepare a uniform microstructure on the surface of the substrate by femtosecond laser micromachining technology.

[0027] Step 3: Coating a layer of 10nm thick high temperature resistant paint on the surface of the microstructure substrate.

[0028] The parameters of the femtosecond laser in the above step 2 are pulse width 50fs, repetition frequency 1kHz, and maximum average power 3W. In actual work, the laser output power is 100mW, and the spot diameter is 200μm. Under this condition, the laser energy density is 3.18kJ / m 2 . When the microstructure is prepared, the movement of the three-dimensional translation stage is cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| processing temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com