Anti-radiation total temperature measuring probe

A technology for measuring probes and radiation protection, which is used in the temperature measurement of moving fluids, measuring devices, and measuring heat. It can solve the problems of small air inlet and outlet, difficult to widely apply, and small airflow insensitive angle range, so as to prolong the service life. , easy to promote and use, reduce the effect of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

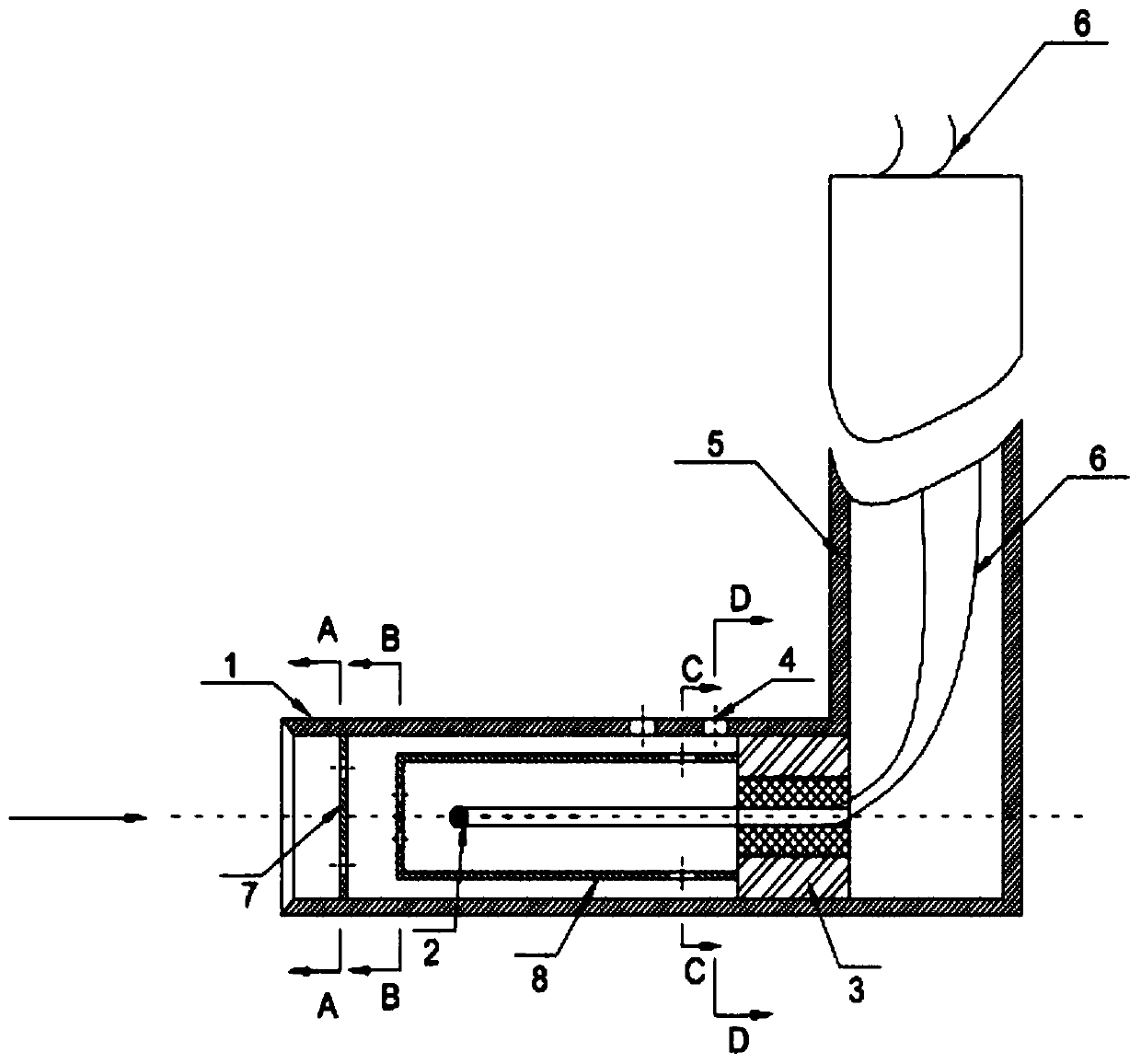

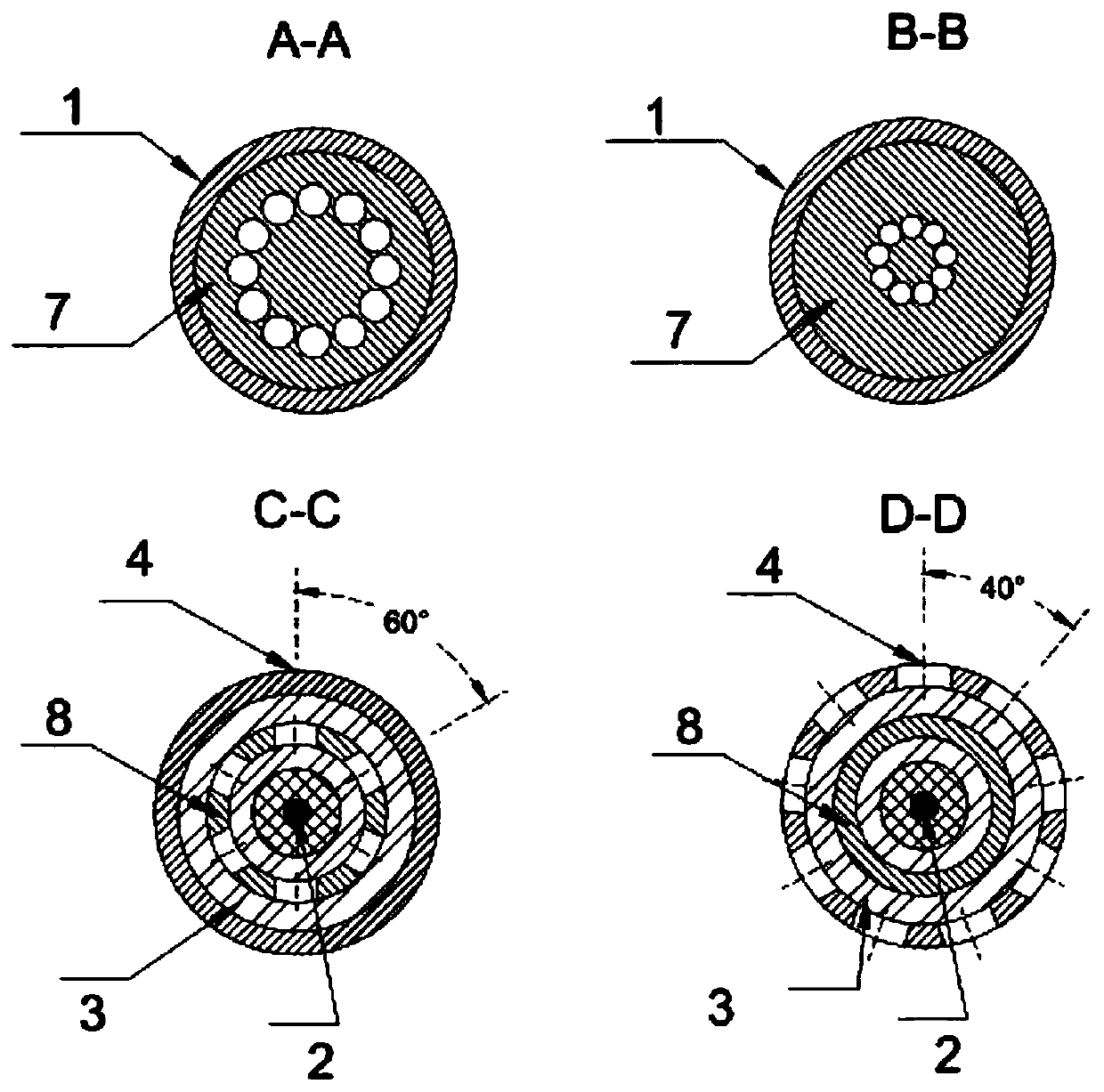

[0017] Such as figure 1 As shown, the radiation-proof total temperature measurement probe of the present invention includes a stagnation cover (1), a temperature sensor (2), a heat insulation seal (3), a convection heat exchange hole (4), and a probe support rod (5) , The temperature measurement lead (6), the shielding cover (7) and (8), the temperature sensor (2) is a thermocouple, and the flow direction is shown by the arrow in the figure. The stagnation cover (1) and the probe support rod (5) The connection is an "L" shape, in which the diameter of the stagnation cover (1) is 7 mm, and the diameter of the probe support rod (3) is 7 mm. One end of the stagnation cover (1) is provided with an air inlet with a diameter of 6 mm and a 60° chamfer. There are 18 convection heat exchange holes (4) on the side wall of the stagnation cover (1). The shape of the holes is Circular, with a hole diameter of 2 mm. Along each axial position of the stagnation cover (1), 9 convection heat exc...

Embodiment example 2

[0020] Such as figure 1 As shown, the radiation-proof total temperature measurement probe of the present invention includes a stagnation cover (1), a temperature sensor (2), a heat insulation seal (3), a convection heat exchange hole (4), and a probe support rod (5) , Temperature measuring lead (6), shielding cover (7) and (8), temperature sensor (2) is an optical fiber sensor, the direction of incoming flow is shown by the arrow in the figure, the stagnation cover (1) and the probe support rod (5) The connection is an "L" shape, in which the diameter of the stagnation cover (1) is 8 mm, and the diameter of the probe support rod (3) is 8 mm. One end of the stagnation cover (1) is provided with an air inlet. The diameter of the inlet hole is 7 mm and has a 60° chamfer. There are 18 convection heat exchange holes (4) on the side wall of the stagnation cover (1). The hole shape is Circular, with a hole diameter of 1.5 mm. Along each axial position of the stagnation cover (1), 9 co...

Embodiment example 3

[0023] Such as figure 1 As shown, the radiation-proof total temperature measurement probe of the present invention includes a stagnation cover (1), a temperature sensor (2), a heat insulation seal (3), a convection heat exchange hole (4), and a probe support rod (5) , Temperature measurement lead (6), shielding cover (7) and (8), temperature sensor (2) is a thermal resistance, the direction of flow is shown by the arrow in the figure, the stagnation cover (1) and the probe support rod (5) The connection is in an "L" shape, in which the diameter of the stagnation cover (1) is 6 mm, and the diameter of the probe support rod (3) is 6 mm. One end of the stagnation cover (1) is provided with an air inlet, the diameter of the inlet hole is 5 mm, and the opening has a 60° chamfer. There are 18 convection heat exchange holes (4) on the side wall of the stagnation cover (1), and the hole shape is Circular, with a hole diameter of 1 mm. Along each axial position of the stagnation cover (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com