Production process control method, device and system

A production process and control method technology, applied in the field of control, can solve the problems of complex process node layout of the production line, production product errors, product entering wrong nodes, etc., to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] In order to facilitate the understanding of this embodiment, the operating environment for implementing a production process control method disclosed in the embodiment of the present application is firstly introduced in detail.

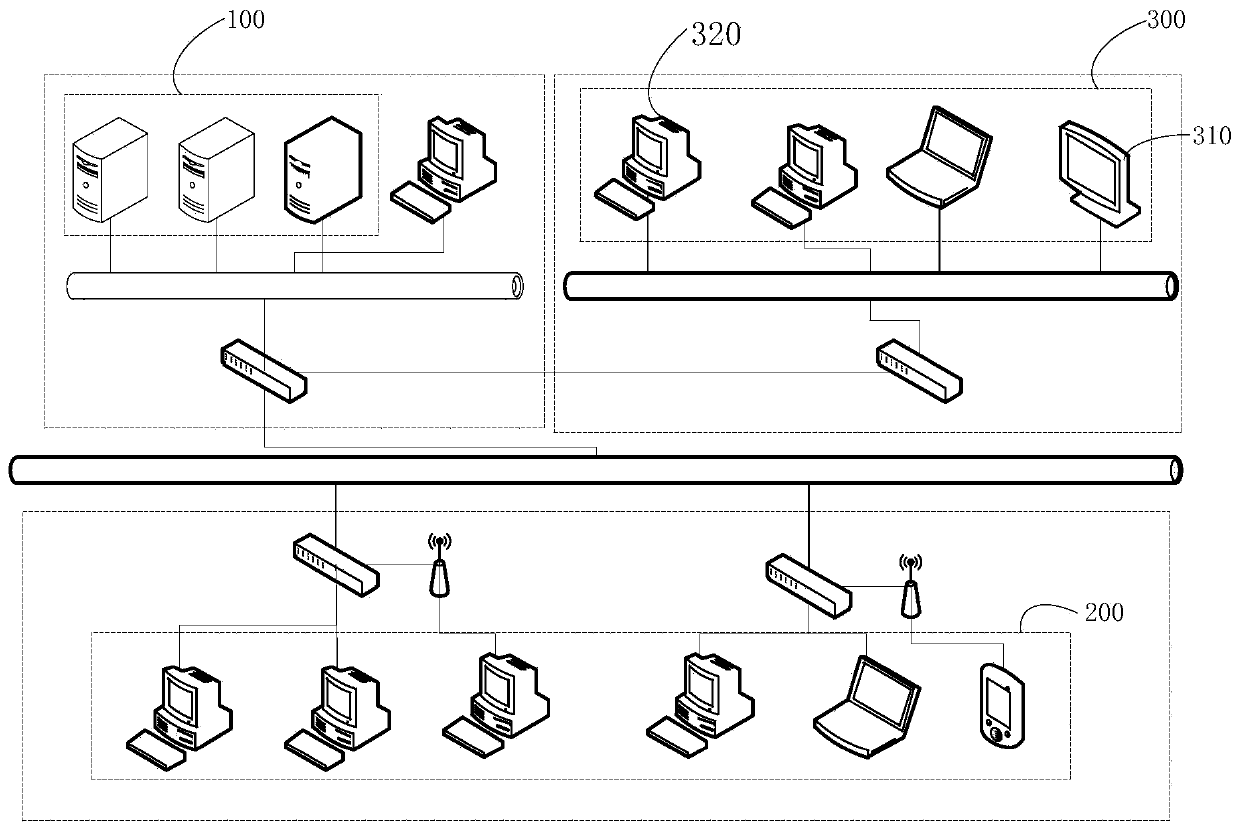

[0062] Such as figure 1 As shown, it is an interactive schematic diagram of the production process control system provided by the embodiment of the present application. In this embodiment, the production process control system may include: one or more production line servers 100 (three production line servers are shown in the figure), and multiple client terminals 200 (two client terminals are shown in the figure). The production line server 100 communicates with a plurality of client terminals 200 through a network for data communication or interaction. The production line server 100 may be a file server, a database server, a Web server, and the like. The client terminal 200 may be a personal computer (personal computer, PC), a tablet comput...

Embodiment 2

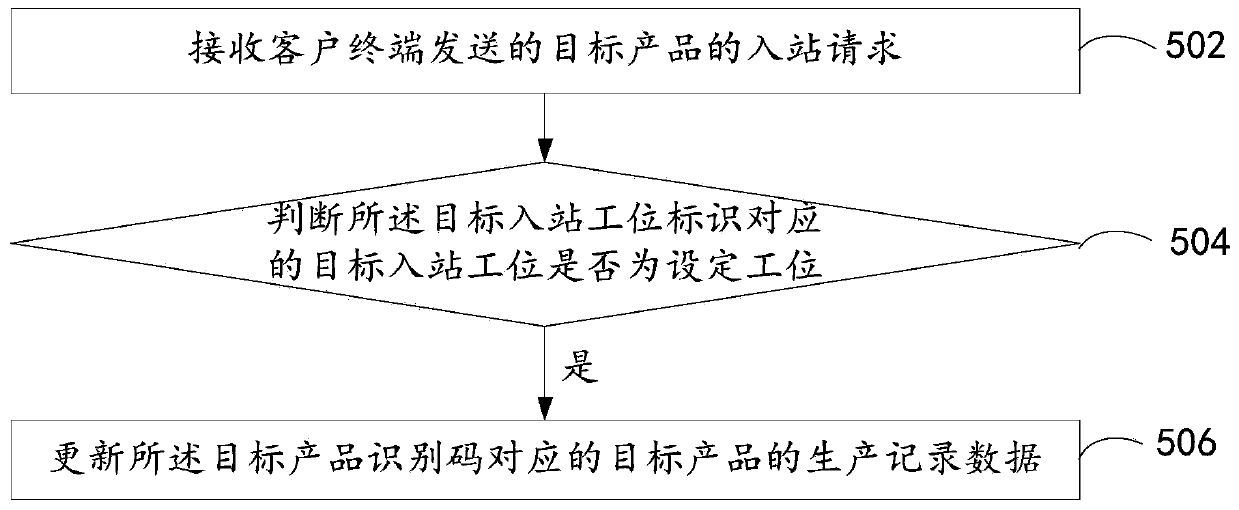

[0076] see image 3 , is a flow chart of the production process control method provided in the embodiment of the present application. The production process control method in this embodiment can be applied to a production line server. The following will be image 3 The specific process shown will be described in detail.

[0077] Step 502, receiving an inbound request for a target product sent by a client terminal.

[0078] Wherein, the inbound request carries inbound data. The inbound data includes target inbound station identification and target product identification code.

[0079] Exemplarily, after any product enters a station of one of the production lines, the customer terminal on the station can obtain the product identification code of the product by scanning the identification code of the product.

[0080] In this embodiment, the client terminal of each station can be bound to the station, and when the client terminal sends a request to the production line server...

Embodiment 3

[0132] Based on the same application concept, the embodiment of this application also provides a production process control device corresponding to the production process control method. Since the problem-solving principle of the device in the embodiment of the application is similar to the aforementioned embodiment of the production process control method, this application For the implementation of the device in the embodiment, reference may be made to the description in the embodiment of the above method, and repeated descriptions will not be repeated.

[0133] see Figure 7 , is a schematic diagram of the functional modules of the production process control device provided in the embodiment of the present application. Each module in the production process control device in this embodiment is used to execute each step in the above method embodiment. The production process control device includes: a first receiving module 601, a first judging module 602 and an updating modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com